Pressure-sensitive adhesive tape, preparation method thereof, and resin composition used for preparing pressure-sensitive adhesive tape

A technology of resin composition and pressure-sensitive adhesive tape, applied in pressure-sensitive adhesive tape and preparation thereof, in the field of resin composition for preparing pressure-sensitive adhesive tape, and can solve the problem of high dielectric constant of optical pressure-sensitive adhesive tape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

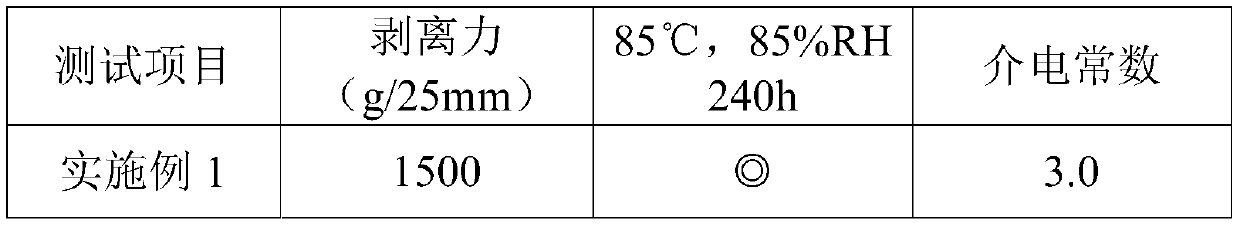

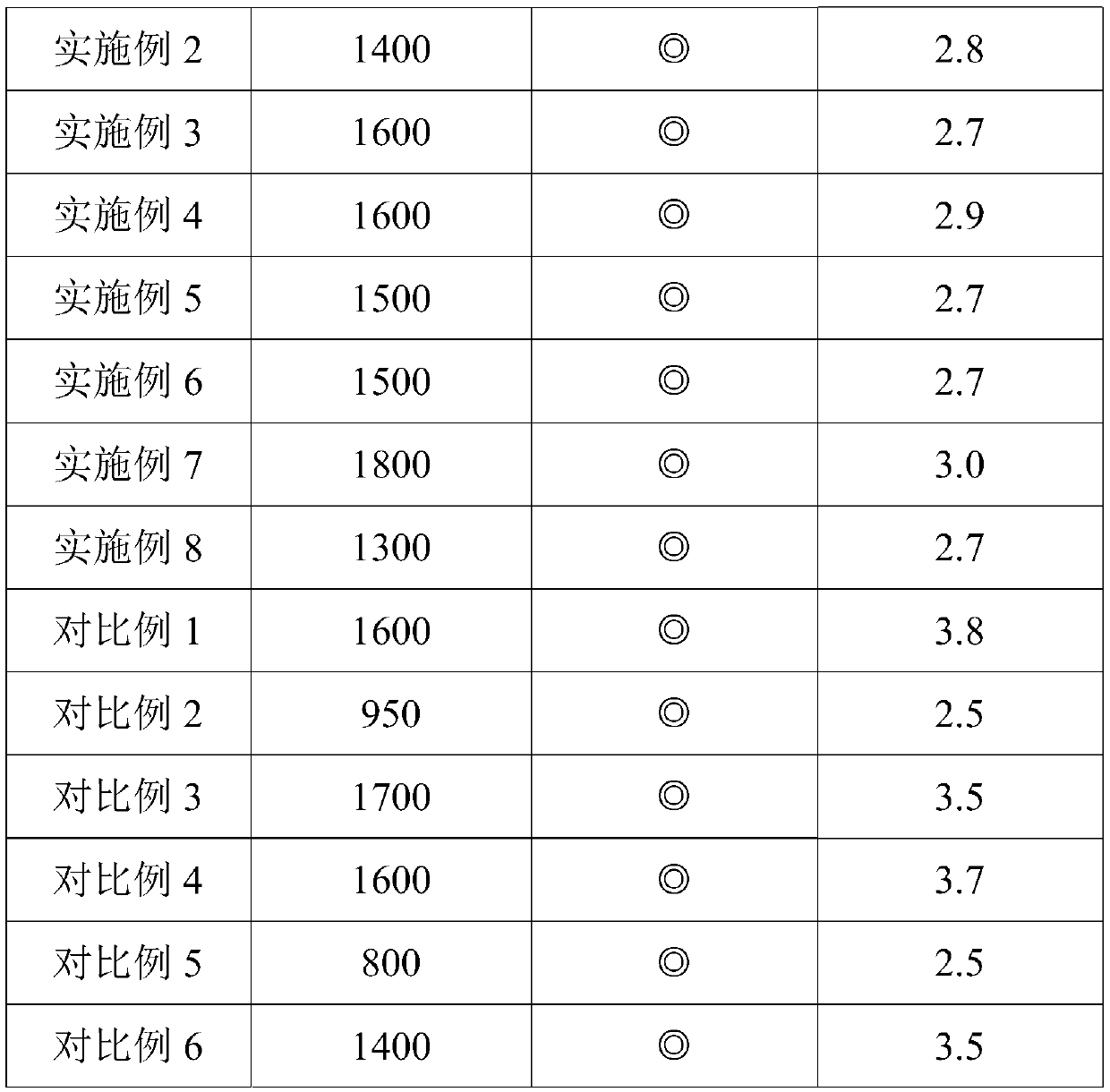

Examples

preparation example Construction

[0073] The embodiment of the present invention also provides a preparation method according to any one of the above-mentioned pressure-sensitive adhesive tapes, including:

[0074] The soft monomer, hard monomer and functional monomer are polymerized to generate a first polyacrylic resin, the polyacrylic resin includes the first polyacrylic resin, and the soft monomer, hard monomer Among the monomers and functional monomers, the mass fraction of polar monomers is 5% to 30%;

[0075] After mixing the first polyacrylic resin with the photopolymerizable monomer, photoinitiator, and curing agent in proportion, a first mixture is formed;

[0076] The first mixture is treated by scraping, drying and UV light (only when the raw material contains photopolymerizable monomers, UV light is required, the same below) to obtain the first tape layer;

[0077] The soft monomer, hard monomer and functional monomer are polymerized to generate a second polyacrylic resin, the polyacrylic resin i...

Embodiment 1

[0095] Take 50g of resin A, add 0.1g of curing agent HDI trimer (hexamethylene diisocyanate), stir evenly, and scrape it on PET (film-forming plate made of polyethylene terephthalic acid plastic) with a hand scraper. film, the solvent is dried in an oven to obtain adhesive tape A1 (ie, the first adhesive tape layer and the third adhesive tape layer above, the same below), and both sides are covered with a release film with a thickness of 25 microns.

[0096] Take 50g of resin B, add 0.1g of curing agent HDI trimer, stir evenly, scrape the film on the PET with a hand scraper, and dry the solvent in an oven to obtain tape B1 (that is, the second tape layer above, and the bottom tape layer below). Same), both sides are covered with release film, the thickness is 100 microns.

[0097] Take tape B1 and A1 and paste them into a two-layer structure A1B1, and then paste a layer of A1 on the other side of B1 to form a three-layer adhesive tape of A1B1A1 (that is, the pressure-sensitive...

Embodiment 2

[0099] Take 50g of resin A, add 5g of photopolymerizable monomer trimethylolpropane triacrylate (TMPTA), 0.1g of photoinitiator 1173, 0.1g of curing agent HDI trimer, stir evenly, and use a hand scraper on the PET Scratch the film, dry the solvent in an oven, and then irradiate with UV light to obtain adhesive tape A2, which is covered with release film on both sides and has a thickness of 25 microns.

[0100] Take 50g of resin B, add 5g of photopolymerizable monomer trimethylolpropane triacrylate (TMPTA), 0.1g of photoinitiator 1173, 0.1g of curing agent HDI trimer, stir evenly, and use a hand scraper on the PET Squeegee the film, dry the solvent in an oven, and then irradiate with UV light to obtain adhesive tape B2, which is covered with a release film on both sides and has a thickness of 100 microns.

[0101] Take the adhesive tape B2 and A2 to form a two-layer structure A2B2, and then attach a layer of A2 to the other side of B2 to form a three-layer adhesive tape of A2B2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com