Electric heating equipment for heating crude oil and temperature control method of electric heating equipment

An electric heating and electric heating tube technology, applied in mechanical equipment, pipeline systems, gas/liquid distribution and storage, etc., can solve the problems of geographical limitations, low heat conversion efficiency, exhaust emissions, etc., to avoid heat loss, High heat conversion efficiency, fire elimination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

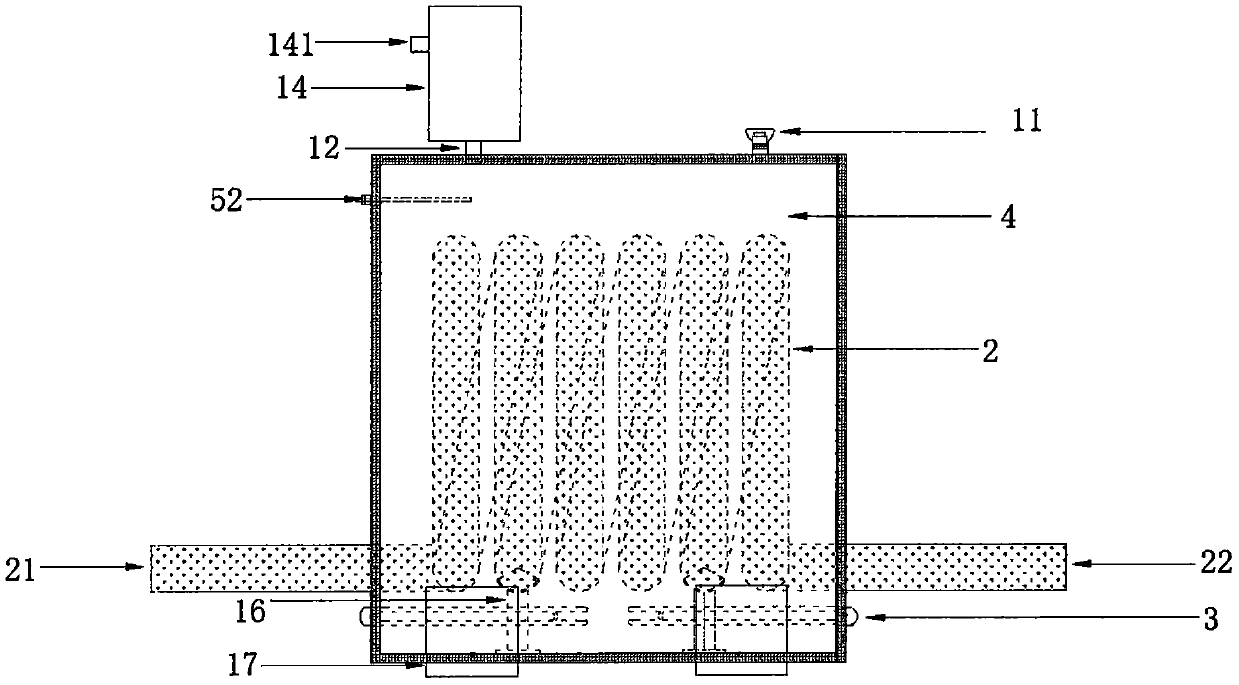

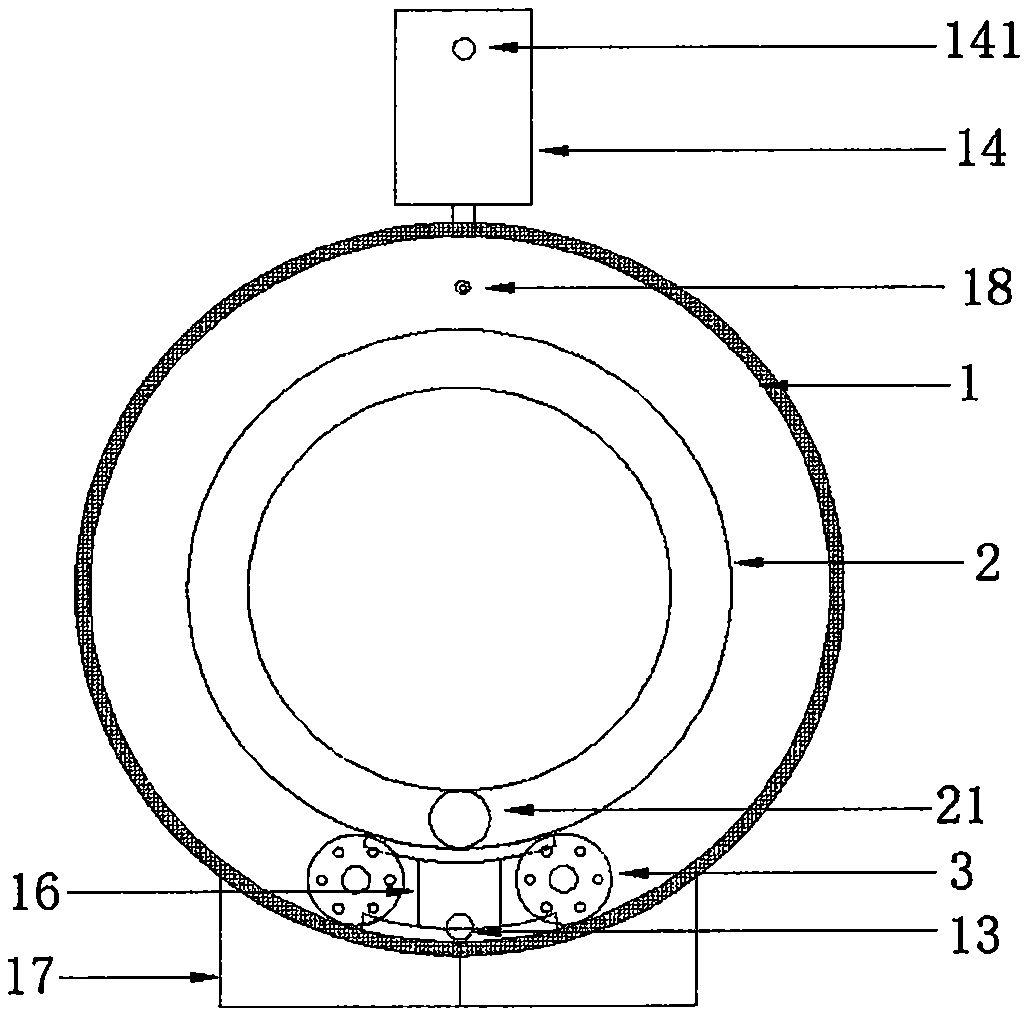

[0036] Figure 1 to Figure 3 It is a structural schematic diagram of the electric heating equipment used for crude oil heating in this embodiment, as Figure 1-3 As shown, the electric heating equipment includes a furnace body 1, an oil delivery coil 2, a plurality of electric heating tubes 3, and a heat-conducting medium 4;

[0037] The oil delivery coil 2 and the electric heating pipe 3 are installed in the inner cavity of the furnace body 1, and the inner cavity of the furnace body 1 is filled with the heat conduction medium 4, and the oil delivery coil Both the coil pipe 2 and the electric heating tube 3 are submerged in the heat-conducting medium 4;

[0038] The oil delivery coil 2 is in a spiral shape, and the oil delivery coil 2 is used as a flow heating chamber for heating crude oil, one end of which is an oil inlet 21, and the other end is an oil outlet 22, and the oil delivery coil 2 The two ends pass through the two sides of the furnace body 1 to the outside of th...

Embodiment 2

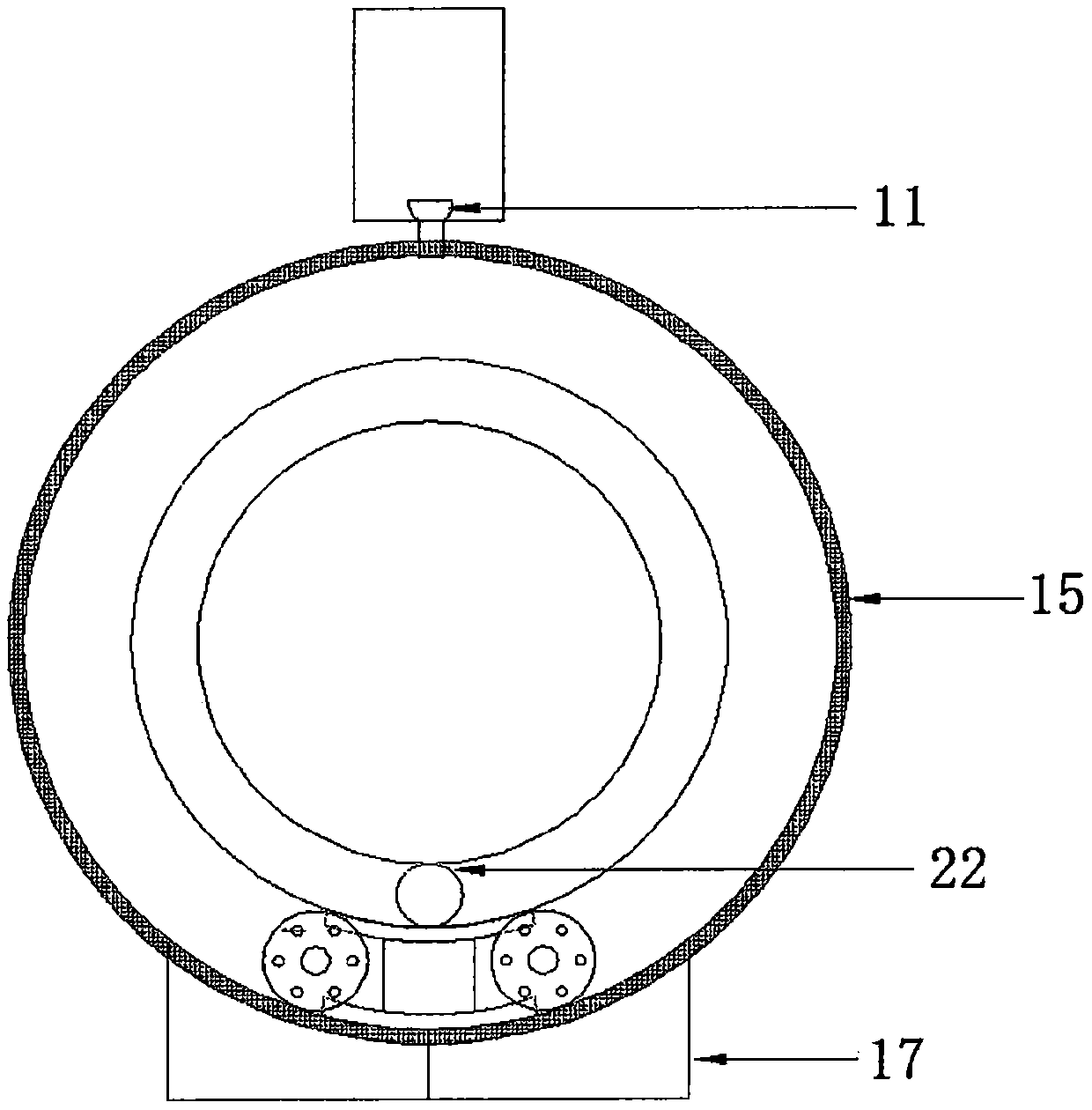

[0097] Figure 6 to Figure 8 It is a structural schematic diagram of the electric heating equipment used for crude oil heating in this embodiment, as Figure 6 to Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that a casing 6 is added outside the furnace body 1, and the casing 6 is provided with an oil inlet and an oil outlet for the oil delivery coil 2 respectively. The inlet 611 and the outlet 612 through the mouth, the shell 6 is also provided with a liquid filling port 613 for the liquid filling pipe 11 to pass through, an exhaust port 614 communicated with the exhaust hole 141 through a hose, and The sewage outlet 615 for the sewage pipe 13 to pass through; the top of the housing is a triangular rainproof cover 64 for rain protection, and a housing door 65 is installed on one side of the housing.

[0098] The interior of the shell 6 is divided into three layers in the horizontal direction, which are respectively a furnace body layer 621, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com