ECT sensor for monitoring moisture transmission inside concrete member

A concrete specimen and concrete technology, applied in the field of ECT sensors, can solve the problems of inability to visualize concrete moisture transmission, inability to quantitatively monitor concrete moisture content, complex structure, etc., to achieve non-destructive monitoring, improve data acquisition speed, and simplify size and quantity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

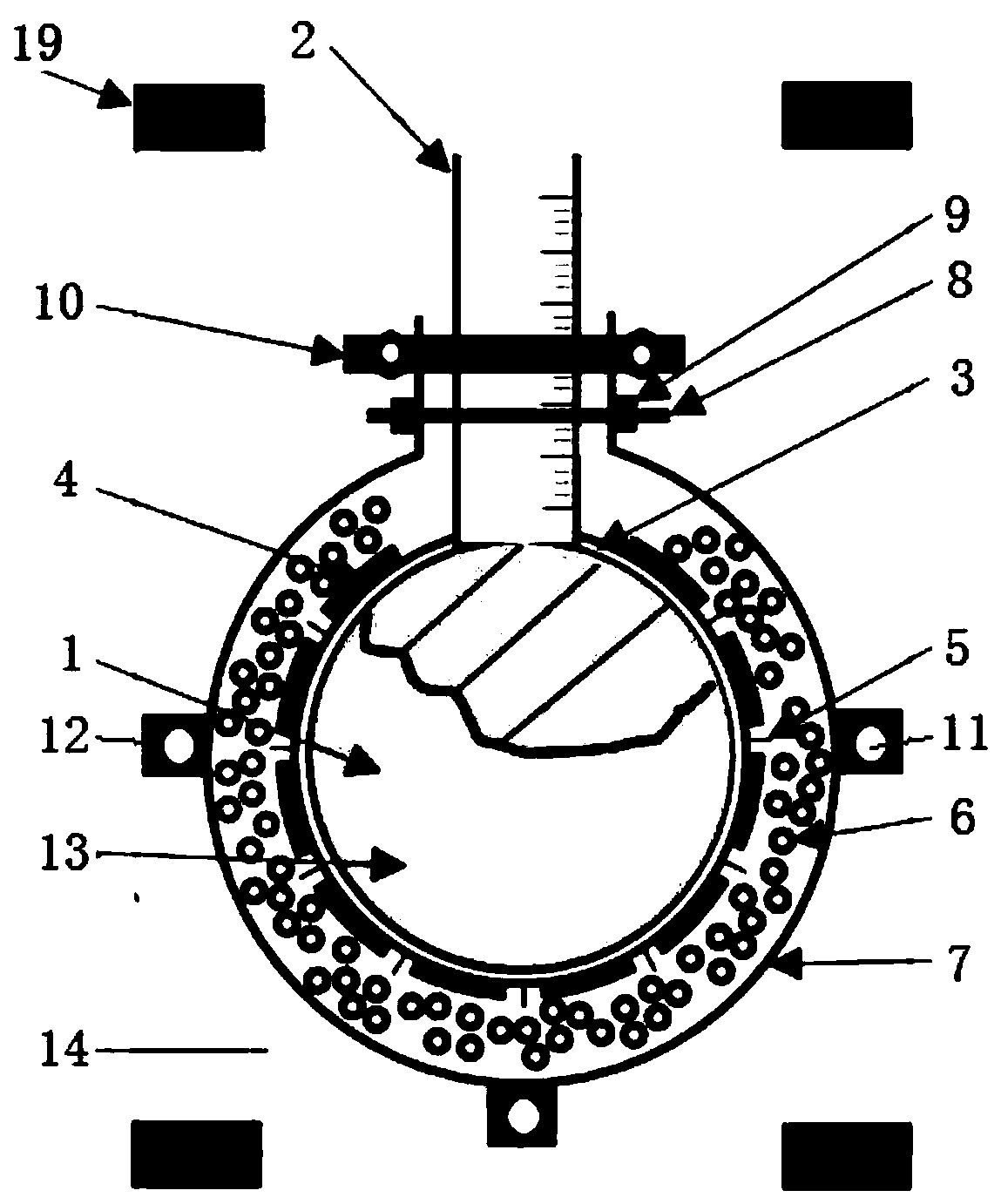

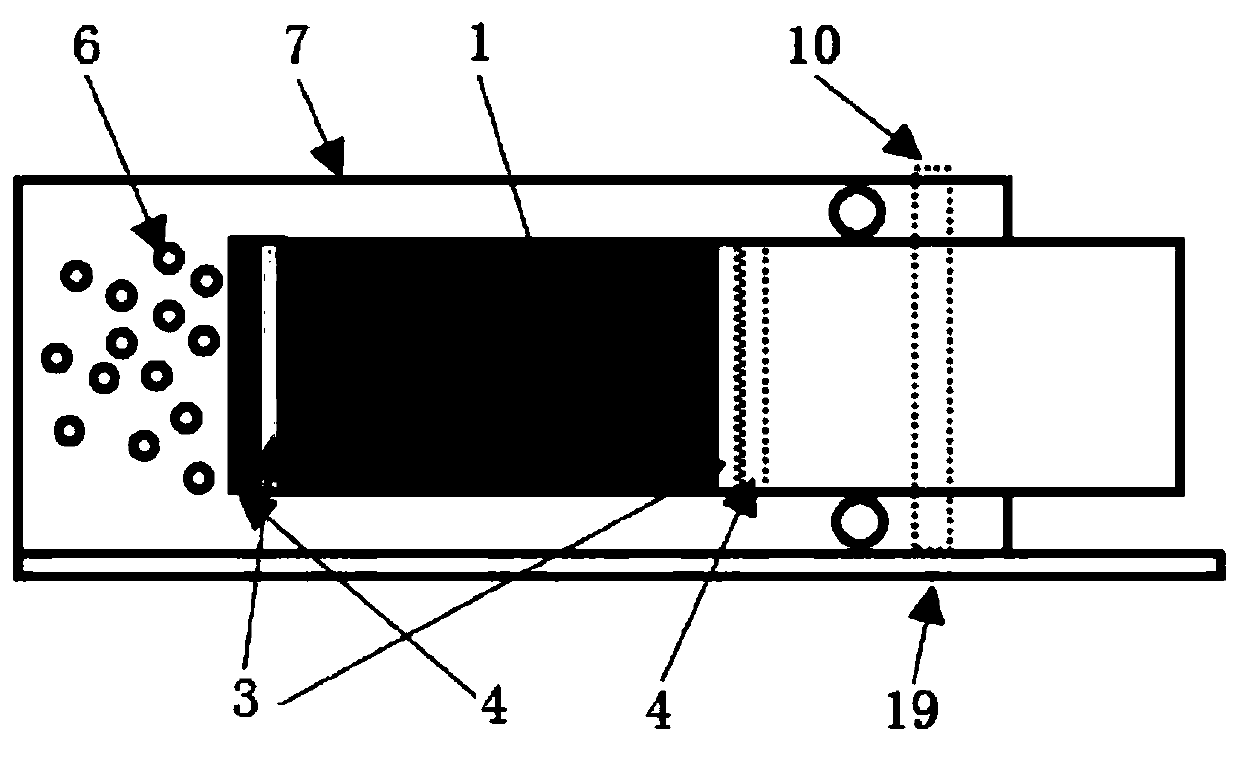

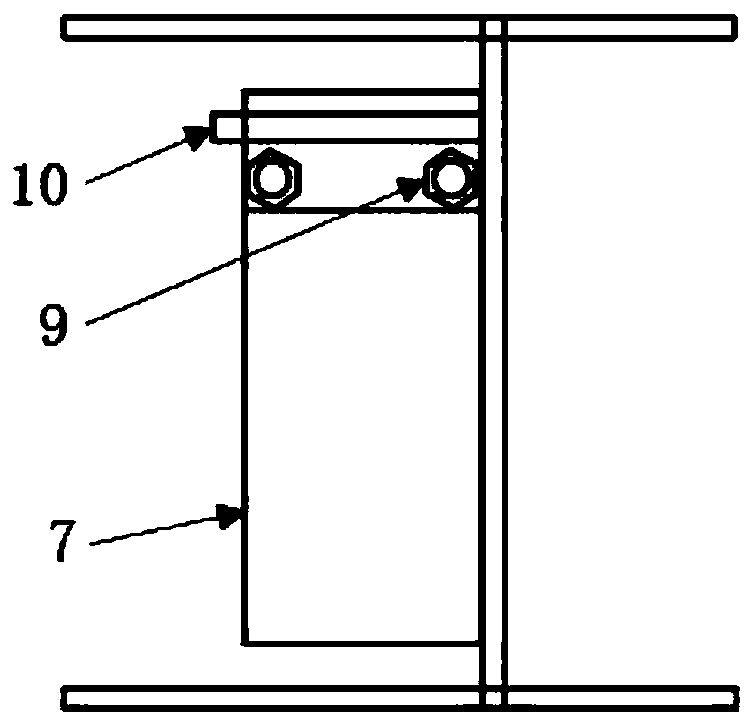

[0023] The main structure of the ECT sensor for monitoring the moisture transmission inside the concrete member involved in this embodiment includes a concrete specimen 1, a water storage tank 2, an insulating pipe 3, an electrode plate 4, a radial shielding electrode 5, an insulating layer 6, a clamp 7, and a threaded rod 8. Nut 9, connector 10, through hole 11, iron sheet 12, top plate 13, bottom plate 14, pad 15, lead hole 16, electrode lead 17, fixing hole 18 and buttress 19; concrete specimen with cylindrical structure A water storage tank 2 is pasted on the side surface of 1, and an insulating tube 3 is laid on the side surface of the concrete specimen 1 where the water storage tank 2 is not pasted. There is a radial shielding electrode 5, the outer periphery of the electrode plate 4 and the radial shielding electrode 5 is covered with an insulating layer 6, the outer periphery of the insulating layer 6 is provided with a clamp 7, the clamp 7 is provided with an opening, ...

Embodiment 2

[0026] The process of performing two-dimensional unsaturated moisture transmission imaging inside cracked concrete with the ECT sensor for monitoring moisture transmission inside concrete members involved in this embodiment includes:

[0027] 1. Connect the electrode lead wire 17 to the port of the PTL300E data acquisition box, and the data acquisition box is connected to the imaging computer through the RS232 port, so that the ECT sensor for monitoring the moisture transmission inside the concrete member, the PTL300E data acquisition box and the imaging computer form an ECT system. , grounding and measuring three measurement modes and linear back projection algorithm: Perform image reconstruction, where C is the normalized capacitance vector, S is the normalized sensitive field matrix, is the normalized permittivity vector;

[0028] 2. Determine the capacitance value of the ECT sensor for monitoring the moisture transmission inside the concrete member without installing co...

Embodiment 3

[0034] The principle of the moisture transmission imaging of the ECT sensor for monitoring the moisture transmission inside the concrete member involved in this embodiment is: different substances have different dielectric constants, and the relative dielectric constant of water is about 80, which is much larger than that of dry concrete ( About 6-8), therefore, after water enters the dry concrete, its relative permittivity changes significantly, which in turn causes a change in the capacitance value. The change in the measured capacitance value reflects the distribution of moisture inside the dry concrete. Multi-electrode The capacitance signals of moisture at different positions measured by the array sensor are used as projection data, and the image reflecting the moisture distribution inside the dry concrete can be reconstructed through the image reconstruction algorithm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com