Seasoning sauce for steaming sweet and sour spareribs and cooking process of sweet and sour spareribs

A technology of sweet and sour pork ribs and seasoning sauce, which is applied in the field of food manufacturing. It can solve problems such as difficulty in controlling the amount of auxiliary materials, unfavorable health of cooks, and sweet and sour pork ribs tend to be acidic, so as to reduce the time and cost of cooking dishes and meet consumer needs. And market demand, the effect of long-lasting fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

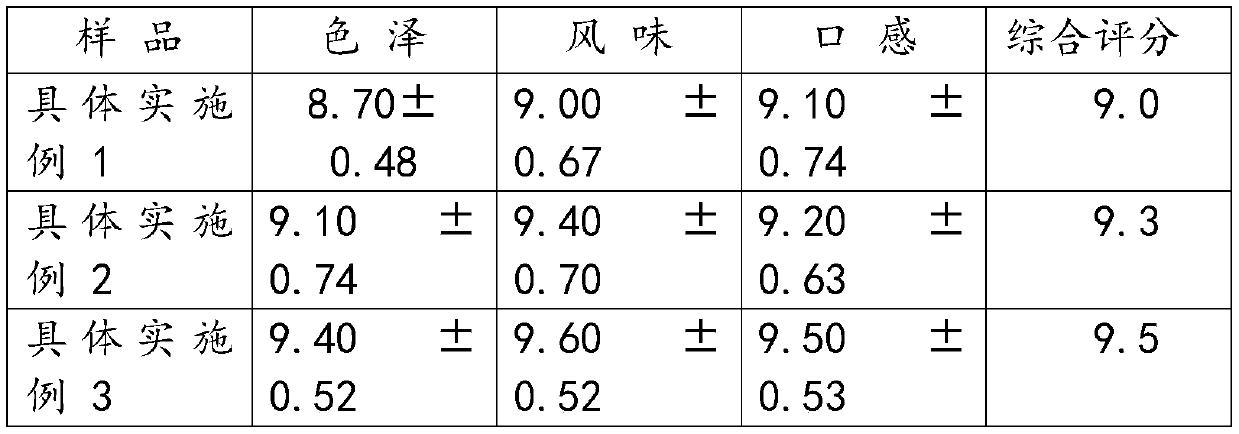

specific Embodiment 1

[0030] A seasoning sauce for steaming sweet and sour pork ribs, the raw materials in the formula and their weight percentages are: 9.0% sour plum sauce, 1.0% hawthorn, 1.0% rice wine, 28% vinegar, 40% white sugar, 12% soy sauce, Edible salt 1.4%, caramel syrup 2.0%, water 1.6%, starch 4.0%.

[0031] Be processed into sweet and sour pork ribs seasoning sauce according to above-mentioned formula, and its processing technology package comprises the following steps:

[0032] (1) Weighing of raw materials: Weigh sour plum sauce, vinegar, white sugar, soy sauce, edible salt, caramel syrup, water, and starch.

[0033] (2) Stir evenly: start stirring, put the weighed material into the mixing tank, pre-mix evenly, and the stirring speed is 80 rpm.

[0034] (3) Cooking: heating the material to a certain temperature and starting to keep warm, the said cooking temperature is 100°C, and the said keeping time is 10 minutes.

[0035] (4) Cooling: Cool the material to a certain temperature,...

specific Embodiment 2

[0043] A recipe for sweet and sour sparerib seasoning sauce, the raw materials in the recipe and their percentages by weight are: 12% sour plum sauce, 1.0% hawthorn, 2.0% rice wine, 30% vinegar, 38% white sugar, 7.0% soy sauce, edible salt 0.50%, caramel syrup 3.0%, water 0.50%, starch 6.0%.

[0044] Be processed into sweet and sour pork ribs seasoning sauce according to above-mentioned formula, and its processing technology package comprises the following steps:

[0045] (1) Weighing of raw materials: Weigh sour plum sauce, vinegar, white sugar, soy sauce, edible salt, caramel syrup, water, and starch.

[0046] (2) Stir evenly: start stirring, put the weighed material into the mixing tank, pre-mix evenly, and the stirring speed is 80 rpm.

[0047] (3) Cooking: heating the material to a certain temperature and starting to keep warm, the said cooking temperature is 85°C, and the said keeping time is 30 minutes.

[0048] (4) Cooling: Cool the material to a certain temperature,...

specific Embodiment 3

[0056] A recipe for sweet and sour pork rib seasoning sauce, the raw materials in the recipe and their weight percentages are: 10% sour plum sauce, 1.0% hawthorn, 0.8% rice wine, 29.5% vinegar, 40% white sugar, 9.0% soy sauce, edible salt 1.0%, caramel syrup 2.5%, water 1.0%, starch 5.2%.

[0057] Be processed into sweet and sour pork ribs seasoning sauce according to above-mentioned formula, and its processing technology package comprises the following steps:

[0058] (1) Weighing of raw materials: Weigh sour plum sauce, vinegar, white sugar, soy sauce, edible salt, caramel syrup, water, and starch.

[0059] (2) Stir evenly: start stirring, put the weighed material into the mixing tank, pre-mix evenly, and the stirring speed is 80 rpm.

[0060] (3) Cooking: heating the material to a certain temperature and starting to keep warm, the said cooking temperature is 90°C, and the said keeping time is 15 minutes.

[0061](4) Cooling: Cool the material to a certain temperature, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com