Efficient foaming type cellulose hydrogel fire extinguishing agent

A cellulose-based, foam-type technology, applied to fire prevention equipment, etc., can solve the problems of cumbersome foam fire extinguishing agent operation, poor fire extinguishing effect, and easy failure of foam, and achieve green environmental protection raw materials, reduce fire losses, and good adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

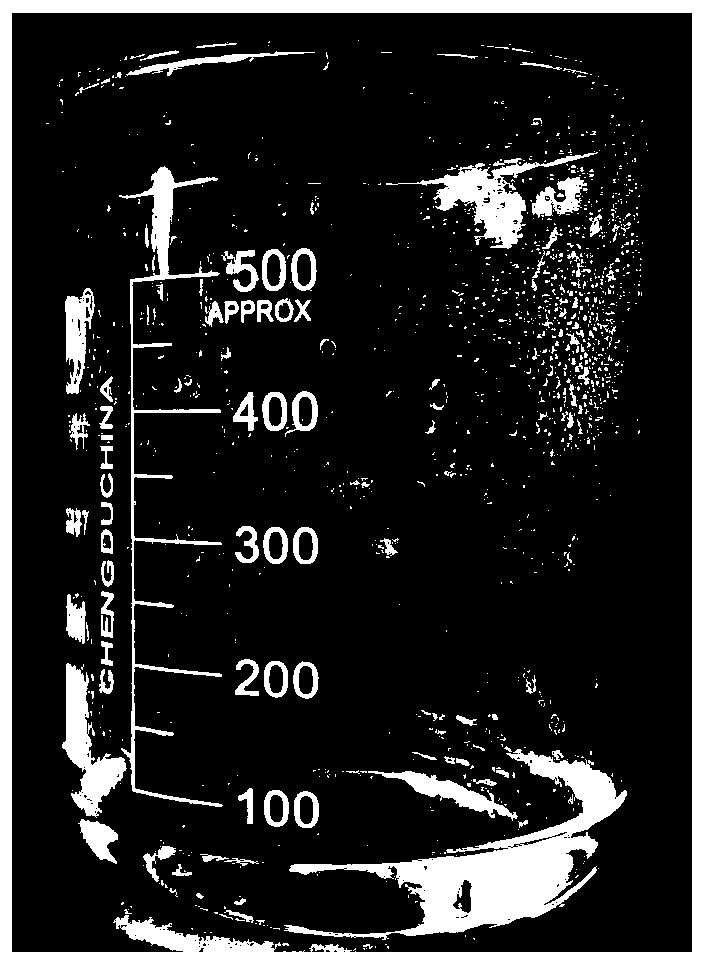

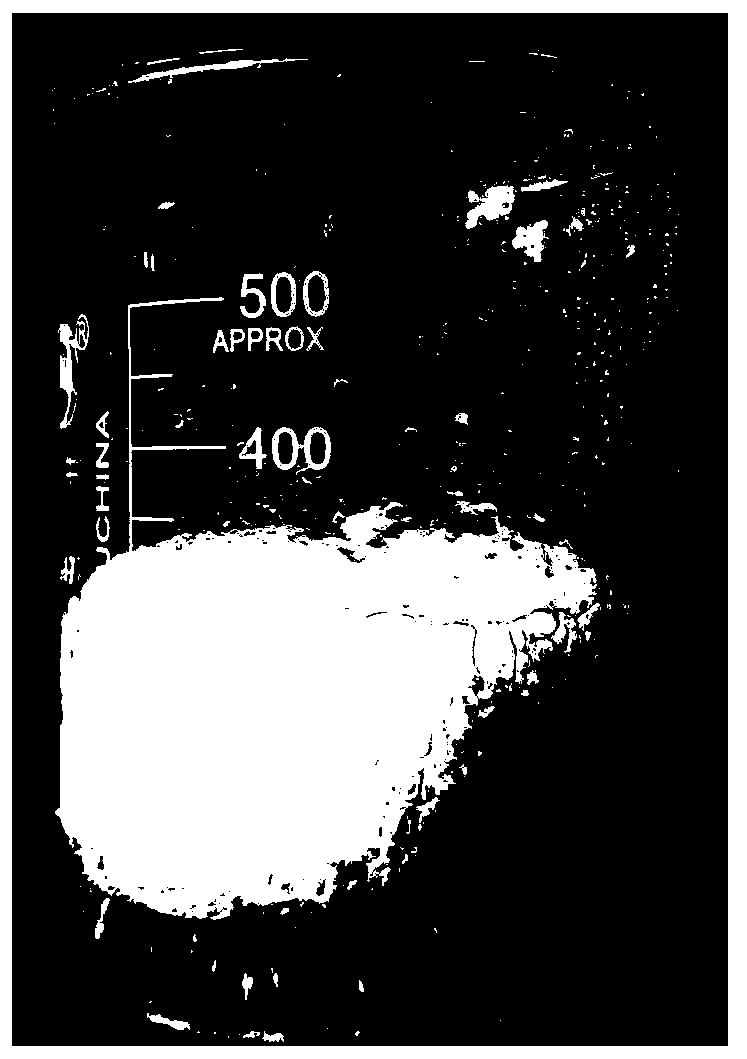

Image

Examples

Embodiment 1

[0030] A high-efficiency foaming cellulose hydrogel fire extinguishing agent is prepared from the following raw material components: A. Sodium carboxymethyl cellulose, B. Sodium bicarbonate, C. Aluminum chloride hexahydrate, D. Ionized water; Its preparation method comprises the following steps:

[0031] (1) 1 part of component A is dissolved in 200 parts of water to obtain solution I, and the mass fraction of A in water in solution I is 0.5wt%;

[0032] (2) 1 part of B component was dissolved in 100 parts of water to obtain solution II, and the mass fraction of B in water in solution II was 1 wt %;

[0033] (3) Mix the above-mentioned solution I and solution II in a closed space to obtain solution III;

[0034] (4) Dissolving 1 part of component C in 200 parts of water to obtain solution IV, the mass fraction of C in water in solution IV is 0.5wt%;

[0035] (5) Spray the mixed solution III and the mixed solution IV onto the surface of the combustible at the same time or spr...

Embodiment 2

[0037] A high-efficiency foaming cellulose hydrogel fire extinguishing agent, prepared from the following raw material components: A. Sodium carboxypropylmethyl cellulose, B. Potassium bicarbonate, C. Aluminum sulfate, D. Deionized Water; its method of preparation and use, comprising the following steps:

[0038] (1) Dissolving 1 part of component A in 50 parts of water to obtain solution I, the mass fraction of A in water in solution I is 2wt%;

[0039] (2) Dissolving 1 part of component B in 200 parts of water to obtain solution II, the mass fraction of B in water in solution II is 0.5wt%;

[0040](3) Mix the above-mentioned solution I and solution II in a closed space to obtain solution III;

[0041] (4) Dissolving 1 part of component C in 100 parts of water to obtain solution IV, the mass fraction of C in water in solution IV is 1 wt %;

[0042] (5) Spray the mixed solution III and the mixed solution IV onto the surface of the combustible at the same time or spray the mi...

Embodiment 3

[0044] A high-efficiency foaming cellulose hydrogel fire extinguishing agent, prepared from the following raw material components: A. Sodium carboxymethyl cellulose, B. Sodium bicarbonate, C. Aluminum chloride hexahydrate, D. Tap water ; Its preparation method comprises the following steps:

[0045] (1) 1 part of component A is dissolved in 100 parts of water to obtain solution I, and the mass fraction of A in water in solution I is 1wt%;

[0046] (2) 1 part of B component was dissolved in 150 parts of water to obtain solution II, and the mass fraction of B in water in solution II was 0.67wt%;

[0047] (3) Mix the above-mentioned solution I and solution II in a closed space to obtain solution III;

[0048] (4) Dissolving 1 part of component C in 150 parts of water to obtain solution IV, the mass fraction of C in water in solution IV is 0.67wt%;

[0049] (5) Spray the mixed solution III and the mixed solution IV onto the surface of the combustible at the same time or spray th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com