Catalyst for continuously producing pentanone by ketene hydrogenation as well as preparation method and application thereof

A catalyst and enone technology, which is applied in the preparation of carbon-based compounds, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the high cost of enone hydrogenation catalysts and the cumbersome operation of the kettle process , power consumption and other problems, to achieve the effect of preventing thixotropy, improving catalyst activity and selectivity, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

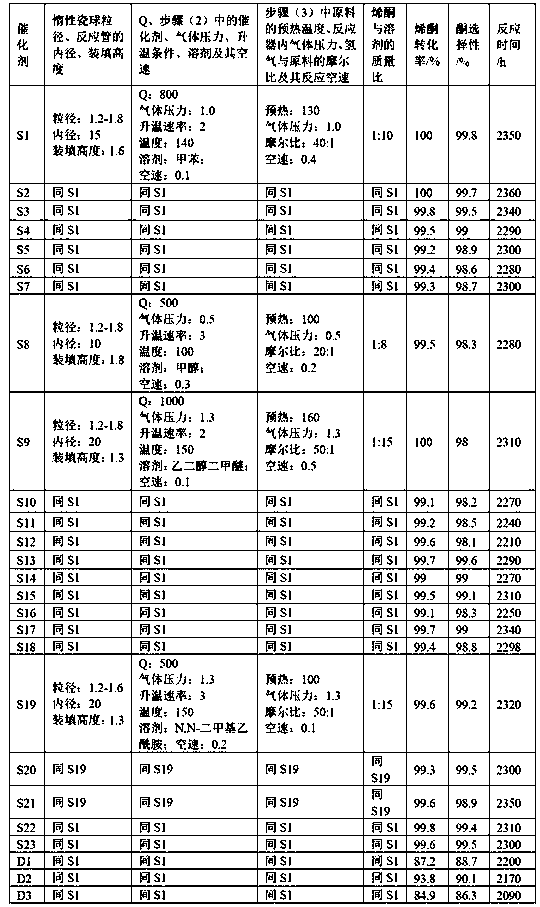

Examples

Embodiment 1

[0044] 1. A catalyst for the continuous production of pentanone by hydrogenation of ketene, consisting of a carrier, an active component and an auxiliary agent attached to the carrier, the active component includes A component and B component, and the auxiliary agent includes C component, D component and E component;

[0045] The carrier is pseudo-boehmite containing amorphous silica-alumina, and the SiO in the carrier 2 The content is 0.3-5%, and the specific surface area of the carrier is 160-350m 2 / g, pore volume 0.5 -1.0 cm 3 / g;

[0046] According to the mass percentage of the carrier on a dry basis, the A component is Ni with a content of 60%, the B component is Mo with a content of 8%, and the C component is Zn with a content of 6%. The D component is Ce with a content of 1%, and the E component is B with a content of 1.3%;

[0047] 2. the preparation method of described catalyst, comprises the following steps:

[0048] (1) The carrier was dried at 80°C to const...

Embodiment 2

[0055] 1. A catalyst for the continuous production of pentanone by hydrogenation of ketene, consisting of a carrier, an active component and an auxiliary agent attached to the carrier, the active component includes A component and B component, and the auxiliary agent includes C component, D component and E component;

[0056] Described carrier is with embodiment 1;

[0057] According to the mass percentage of the carrier on a dry basis, the A component is Ni with a content of 60%, the B component is Mo with a content of 10%, and the C component is Zn with a content of 5%. The D component is Ce, and the content is 1.1%, and the E component is B, and the content is 1.5%;

[0058] The preparation method is the same as in Example 1, and the obtained catalyst is denoted as S2.

Embodiment 3

[0060] 1. A catalyst for the continuous production of pentanone by hydrogenation of ketene, consisting of a carrier, an active component and an auxiliary agent attached to the carrier, the active component includes A component and B component, and the auxiliary agent includes C component, D component and E component;

[0061] Described carrier is with embodiment 1;

[0062] According to the mass percentage of the carrier on a dry basis, the A component is Ni with a content of 65%, the B component is Mo with a content of 9%, and the C component is Zn with a content of 7%. The D component is Ce, and the content is 0.8%, and the E component is B, and the content is 1.2%;

[0063] The preparation method is the same as in Example 1, and the obtained catalyst is denoted as S3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com