Device and method for controlling vibration during motion control carried out on flexible workpieces by robots

A robot and motion technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problem of not being able to predetermine the total running time of the trajectory, and achieve the effect of suppressing residual vibration, improving tracking accuracy, and improving production quality and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

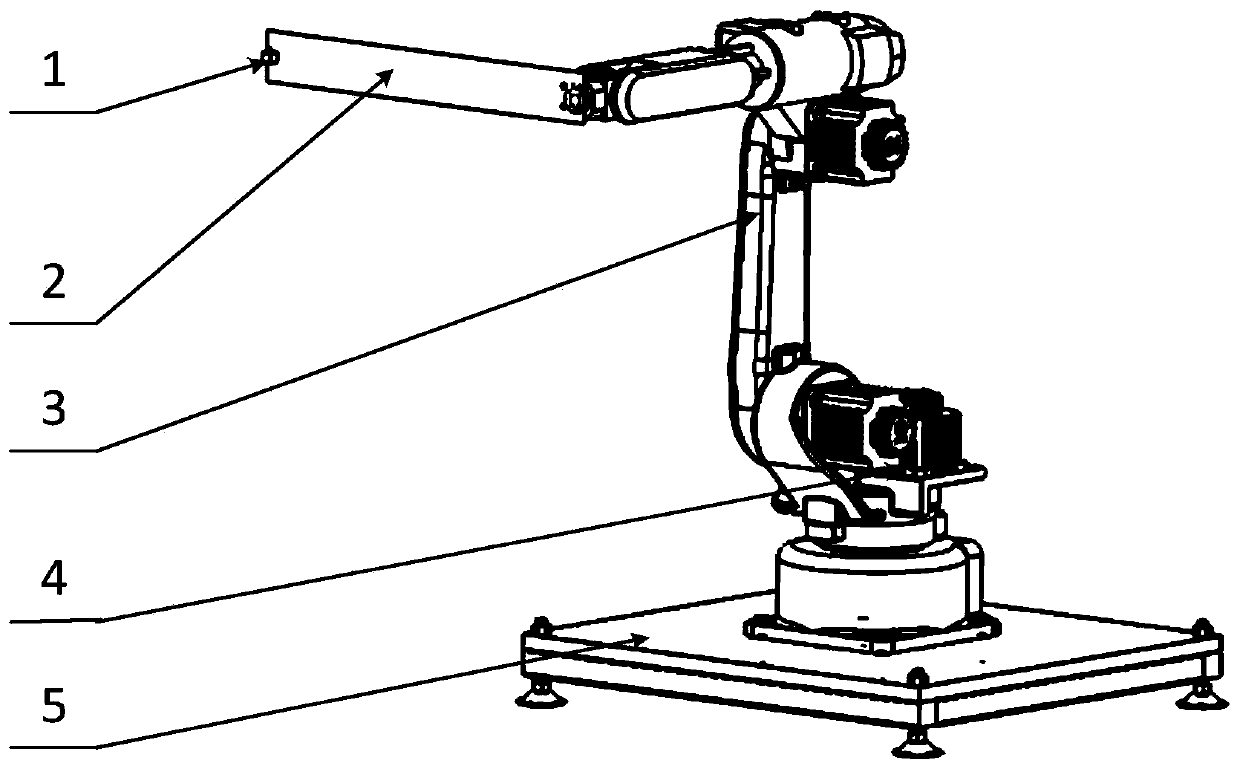

[0055] Now take a six-degree-of-freedom series-joint industrial robot manipulating a flexible workpiece as the vibration control object as an example to further illustrate the present invention.

[0056] Such as figure 1 As shown, the test device for vibration control when the robot of this embodiment manipulates the flexible workpiece to move, the test device includes: a data processing module, a motion test module, and a signal acquisition module;

[0057]The data processing module adopts Huayan IPC-510 embedded industrial computer, including a human-computer interaction unit, a real-time control unit, and a vibration suppression algorithm realization unit; the human-computer interaction unit, real-time control unit, and vibration suppression algorithm realization unit are all in Developed on the Microsoft Visual Studio 2017 platform, the anti-vibration algorithm implementation unit includes a trajectory generator for designing the trajectory of the robot; the real-time cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com