Water softening treatment system carrying TBM high-pressure water coupling rock breaking and softening method

A treatment system and water softening technology, applied in water/sludge/sewage treatment, ion-exchanged water/sewage treatment, mining wastewater treatment, etc., can solve problems such as blockage of pipes, poor water softening effect in high-pressure water systems, etc. Achieve good compatibility, improve softening efficiency, and improve driving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

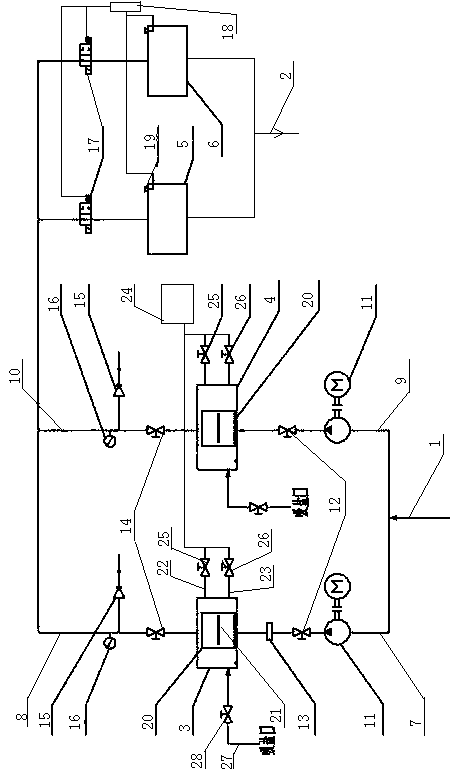

[0029] Such as figure 1 Shown, embodiment 2, a kind of softening method of the water softening treatment system that carries TBM high-pressure water coupling rock breaking, comprises the following steps:

[0030] S1: Before TBM operation, debug the water softening treatment system;

[0031] S2: Turn on the booster pump 11 and the first on-off valve 12 on the first water inlet pipe 7 and the second water inlet pipe 9, and the soft water in the water supply system enters the first softened water treatment device 3 and the second softened water treatment device 4. Raw water is softened;

[0032] S3: In step S2, the first softened water treatment device 3 and the second softened water treatment device 4 carry out simultaneous softening and alternate regeneration of the two tanks, and continuously soften the raw water; taking the regeneration of the softened water tank as an example, this process will In the process of positive washing, backwashing, salt suction and slow washing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com