Processing method of environment-friendly polyurethane adhesive

A technology of polyurethane adhesives and processing methods, applied in the field of polymers, can solve problems such as the need to improve the bonding strength of adhesives, the difficulty of recycling materials, and the impact on the health of operators, achieving strong reusability and easy promotion Application, with reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

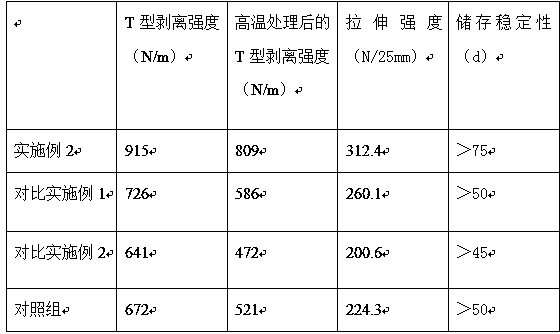

Examples

Embodiment 1

[0031] A processing method of an environmentally friendly polyurethane adhesive, comprising the steps of:

[0032] (1) Preparation of compound additives:

[0033] a. First mix cerium nitrate, aluminum nitrate, and deionized water into the mixing tank according to the weight ratio of 1:0.5:45. After stirring for 30 minutes, add a layer of 8% of the total mass of deionized water into the mixing tank. Analyze the silica gel, then filter after stirring for 8 hours, put the filtered silica gel into a muffle furnace, heat and roast for 3 hours, and then take it out to obtain loaded silica for subsequent use;

[0034] b. Take the following materials in corresponding parts by weight: 25 parts of tea polyphenols, 55 parts of ethyl acetate, 15 parts of acetic anhydride, 3 parts of disodium ethylenediaminetetraacetic acid, 2 parts of loaded silicon dioxide obtained from operation a; then Put all the above substances into the reaction kettle together, heat to keep the temperature in the ...

Embodiment 2

[0053] A processing method of an environmentally friendly polyurethane adhesive, comprising the steps of:

[0054] (1) Preparation of compound additives:

[0055] a. First mix cerium nitrate, aluminum nitrate, and deionized water into the mixing tank according to the weight ratio of 1:0.7:48. After stirring for 33 minutes, add a layer of 9% of the total mass of deionized water into the mixing tank. Analyze the silica gel, then filter after stirring for 9 hours, put the filtered silica gel into a muffle furnace, heat and roast for 3.5 hours, then take it out to obtain loaded silica for subsequent use;

[0056] b. Take the following materials in corresponding parts by weight: 27 parts of tea polyphenols, 56 parts of ethyl acetate, 17 parts of acetic anhydride, 5 parts of disodium ethylenediaminetetraacetic acid, 4 parts of supported silicon dioxide obtained from operation a; Put all the above substances into the reaction kettle together, heat to keep the temperature in the reac...

Embodiment 3

[0075] A processing method of an environmentally friendly polyurethane adhesive, comprising the steps of:

[0076] (1) Preparation of compound additives:

[0077] a. First mix cerium nitrate, aluminum nitrate, and deionized water into the mixing tank according to the weight ratio of 1:0.8:50. After stirring for 35 minutes, add a layer of 10% of the total mass of deionized water into the mixing tank. Analyze the silica gel, then filter after stirring for 10 hours, put the filtered silica gel into a muffle furnace, heat and roast for 4 hours, then take it out to obtain loaded silica for subsequent use;

[0078] b. Take the following materials in corresponding parts by weight: 30 parts of tea polyphenols, 60 parts of ethyl acetate, 18 parts of acetic anhydride, 6 parts of disodium ethylenediaminetetraacetic acid, 5 parts of supported silica obtained from operation a; then Put all the above substances into the reaction kettle together, heat to keep the temperature in the reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com