Hydrothermal closed frost heaving and frost boiling prevention high-strength highway subgrade structure and construction method

A closed, anti-frost heave technology, applied in roads, roads, buildings, etc., can solve the problems of road subgrade frost heave, uneven settlement, insufficient strength, etc., to reduce uneven settlement, reduce heat loss, and reduce water content. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

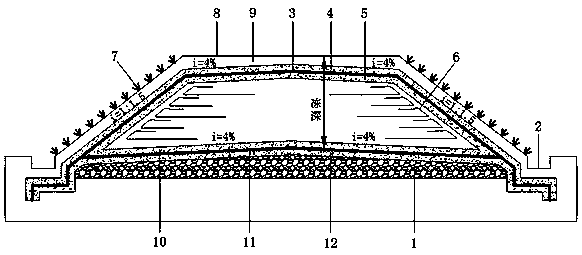

[0044] refer to Figure 1 to Figure 2 ,like Figure 1 to Figure 2 Shown, the specific embodiment of the present invention is as follows:

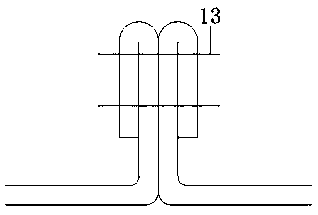

[0045] A hydrothermally enclosed high-strength highway subgrade structure with anti-frost heaving and slurrying. The overall longitudinal section of the subgrade structure is trapezoidal. The lowest layer of the subgrade structure is a crushed stone layer 1. A gravel protection cushion layer 12, the first waterproof geotextile layer 11, the first gravel protective layer 10, the first gravel protective layer 10 horizontal plane is provided with a geogrid layer 6, the top of the geogrid layer 6 and The second gravel cushion layer 5, the second waterproof geotextile layer 3, the second gravel protection layer 4, and the filling soil layer 9 are arranged sequentially from bottom to top on both sides; the horizontal direction of the filling soil layer 9 is provided with asphalt Surface 8.

[0046] Further, the filling layer 9 on both sides of...

experiment example

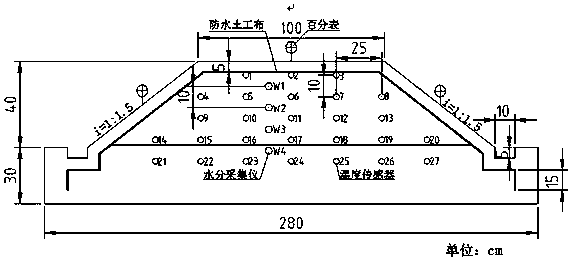

[0064] refer to Figure 3 to Figure 7 ,like Figure 3 to Figure 7 Shown, the concrete embodiment of the experimental example of the present invention is as follows:

[0065] 1. Model experimental equipment:

[0066] A low-temperature model box with a size of 3.5m×2.0m×2.2m, a high-low temperature constant temperature liquid bath circulation device, a dial indicator, a temperature sensor and a soil moisture collector are used.

[0067] 2. Model filling process:

[0068] (1) Soil sample preparation

[0069] Select Lanzhou loess as the test soil sample. Before the experiment, sprinkle water evenly on the soil sample, cover it with a plastic film and let it stand for 3 days to make the moisture distribution in the test soil sample even;

[0070] (2) Subgrade filling

[0071] Adopt toughened glass to separate the low-temperature model box into two parts of the same size, one part is filled with the roadbed model of the present invention, that is, the new roadbed in the accompa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap