Small-section channel lining construction method

A construction method and small-section technology, applied in water conservancy projects, artificial waterways, buildings, etc., can solve problems such as channel seepage, achieve the effect of preventing water seepage, good anti-seepage effect, and ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A small-section channel lining construction method, comprising:

[0046] Step 1, measure and stake out, measure and stake out at the plane position of the excavated channel, use a total station or theodolite to define the central positioning pile and the bottom slope junction pile, drive the center pile along the direction of the excavated channel and at a predetermined interval distance Numbering, use a level to measure the height of the pile point, and then determine the sideline of the excavated channel according to the center line, and mark it with a marking machine;

[0047] Step 2, channel filling, the channel filling uses the nearby land to arrange and excavate the earthwork, and lay and fill according to the horizontal layer;

[0048] Step 3: Excavation of the channel, using backhoe equipment for one-time excavation and forming, using rolling rollers to roll the bottom and sides of the channel, after the rolling is completed, spray one-component polyurethane wat...

Embodiment 2

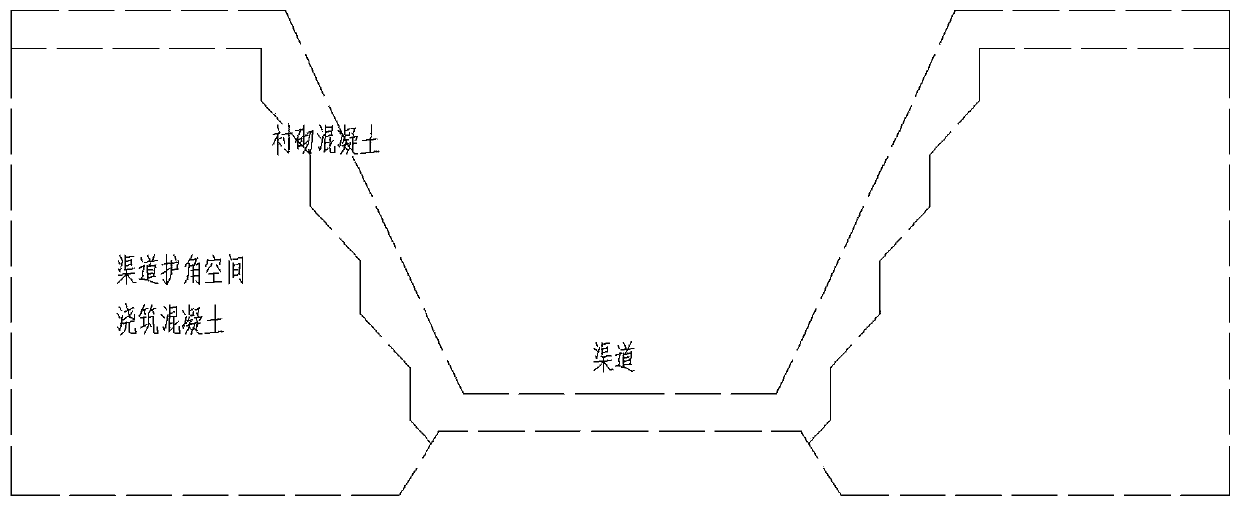

[0062] Such as figure 1 As shown, step 3 also includes the step of digging and setting up channel corner protection spaces, and the channel corner protection spaces are set on both sides of the excavated channel section.

[0063] Step 4 or step 5 also includes the step of using concrete to pour the corner space of the channel.

[0064] During the daily maintenance of the channel, due to the surface deformation or the quality of the channel lining, the channel lining concrete often cracks. In order to solve the above technical problems, in the area where channel deformation is likely to occur, pouring in the channel corner protection space is adopted. Concrete is used as a clamping concrete lining structure. When lining the channel, the channel and the concrete poured in the corner space of the channel are integrated into one. As an improvement of this embodiment, the concrete poured in the channel corner space is replaced with reinforced concrete. As another improvement of th...

Embodiment 3

[0066] Step 4 also includes the step of pouring a cement slurry layer on the sand and pebble cushion. The poured cement slurry is conducive to the formation of a stable whole of the sand and pebble cushion to support the lining concrete. This embodiment only limits the step of pouring the cement slurry layer on the sand and pebble cushion layer. Except for the above definition, this embodiment is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com