Lithium ion battery pole piece, preparation method thereof and lithium ion battery

A lithium-ion battery and pole piece technology, applied in electrode manufacturing, battery electrode, electrode collector coating, etc., can solve the problems affecting the charging and discharging process, limited improvement of battery energy density and power performance, etc. Ionic conductivity, improving electron conductivity and lithium ion transport properties, improving the effect of lithium ion transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

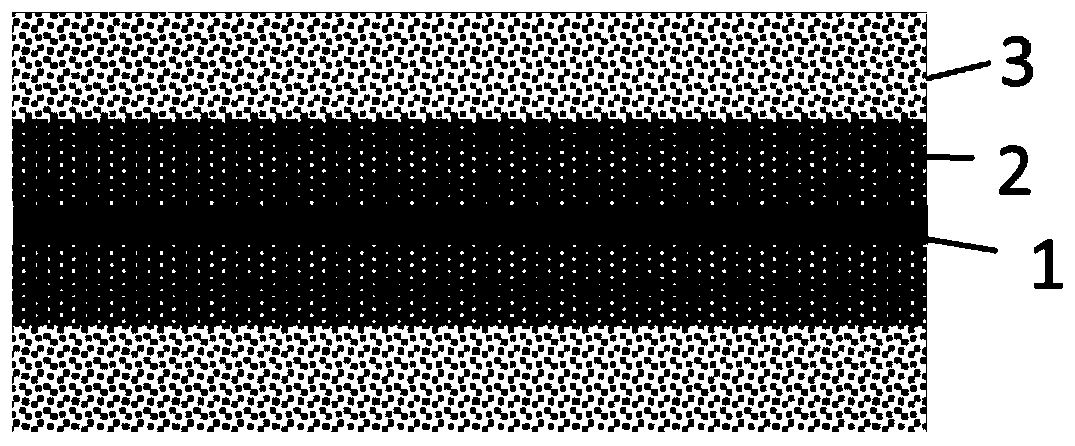

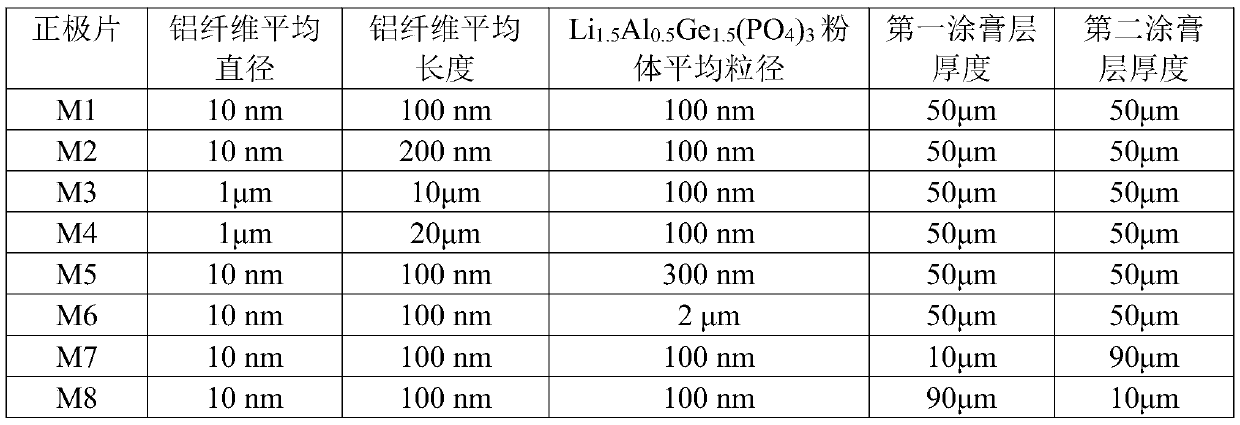

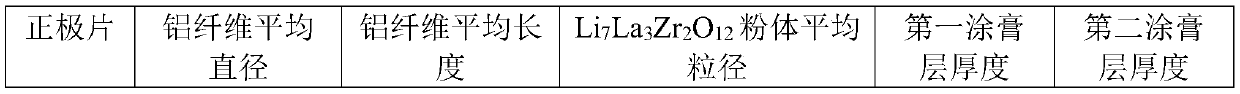

[0026] A lithium-ion battery positive sheet, comprising a positive current collector 1, a first paste layer 2 and a second paste layer 3, the first paste layer 2 is coated on one surface of the positive current collector 1, the first Two paste layers 3 are coated on the surface of the first paste layer 2, and the first paste layer 2 includes uniformly dispersed positive electrode active materials, conductive agents, binders and metal fibers, and the second paste layer 3 includes uniformly dispersed positive electrode active material, conductive agent, binder and fast ion conductor material.

[0027] Further, the thickness of the first paste layer is between 5-300 μm; preferably, the thickness of the first paste layer is between 5-150 μm.

[0028] Further, the thickness of the second paste layer is between 5-300 μm; preferably, the thickness of the second paste layer is between 5-150 μm.

[0029] Further, the total thickness of the first paste layer and the second paste layer ...

specific Embodiment approach 2

[0041] A lithium-ion battery negative electrode sheet, comprising a current collector 1, a first paste layer 2 and a second paste layer 3, the first paste layer 2 is coated on one surface of the negative electrode current collector 1, and the second The paste layer 3 is coated on the surface of the first paste layer 2, and the first paste layer 2 includes a uniformly dispersed negative electrode active material, a conductive agent, a binding agent and metal fibers, and the second paste layer 3 It includes uniformly dispersed negative electrode active material, conductive agent, binder and fast ion conductor material.

[0042] Further, the thickness of the first paste layer is between 5-300 μm; preferably, the thickness of the first paste layer is between 5-150 μm.

[0043] Further, the thickness of the second paste layer is between 5-300 μm; preferably, the thickness of the second paste layer is between 5-150 μm.

[0044] Further, the total thickness of the first paste layer ...

specific Embodiment approach 3

[0057] A lithium-ion battery positive plate, comprising a current collector 1, a first paste layer 2 and a second paste layer 3, the first paste layer 2 is coated on both surfaces of the positive current collector 1, the first Two paste layers 3 are coated on the surface of the first paste layer 2, and the first paste layer 2 includes uniformly dispersed positive electrode active materials, conductive agents, binders, metal fibers, and the second paste layer 3 includes uniformly dispersed positive electrode active material, conductive agent, binder and fast ion conductor material.

[0058] Further, the thickness of the first paste layer is between 5-300 μm; preferably, the thickness of the first paste layer is between 5-150 μm.

[0059] Further, the thickness of the second paste layer is between 5-300 μm; preferably, the thickness of the second paste layer is between 5-150 μm.

[0060] Further, the total thickness of the first paste layer and the second paste layer is between...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com