An anti-vibration modular reinforced lightning protection connector assembly for power supply

A connector assembly and reinforced technology, which is applied in the field of anti-vibration modular reinforced power lightning protection connector assembly, can solve the problems of poor environmental resistance of plastic parts reinforcement, detachment of connecting cables, and less contact of contacts, etc., to achieve good Reinforcement effect, good sealing and environmental resistance, guarantee the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

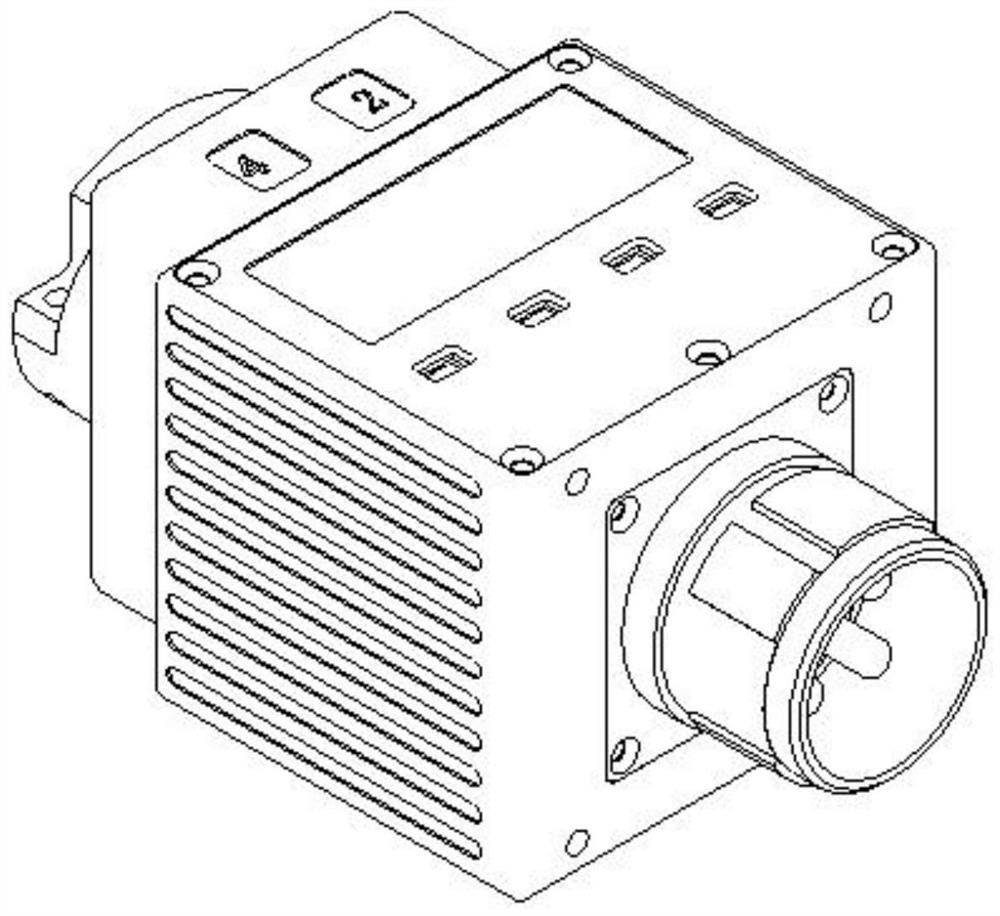

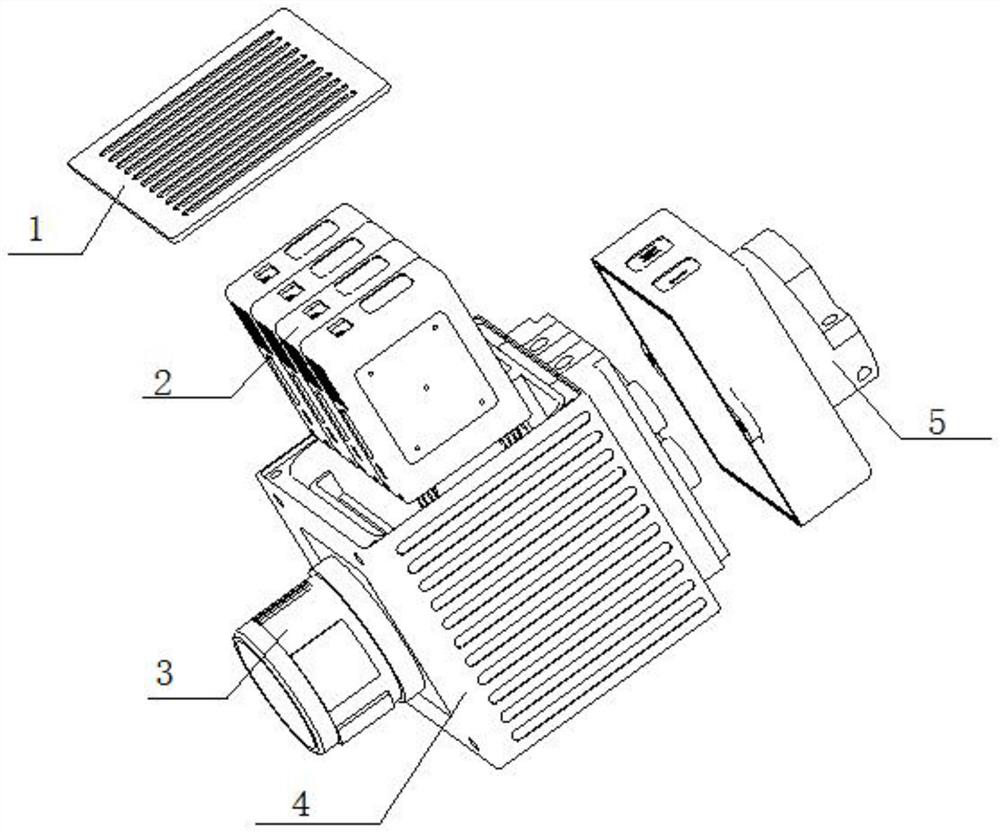

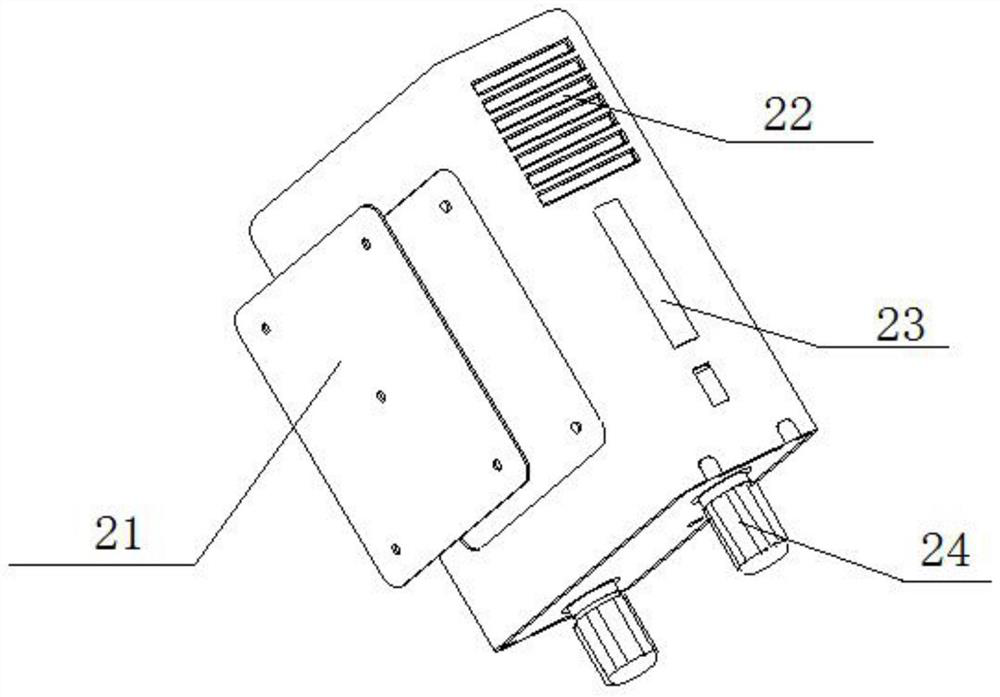

[0033] A specific embodiment of the present invention discloses an anti-vibration modular reinforced power supply lightning protection connector assembly, including a metal shell 4, a plug-in module 2, a connector interface 3 and a stress relief device, and the plug-in module 2 is installed on In the metal shell 4 , a lightning protection core device is arranged inside the plug-in module 2 , and the connector interface 3 is installed at the input end of the metal shell 4 for connecting with the plug to realize signal communication. The appearance and structure of the anti-vibration modularized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com