System and method for manufacturing secondary battery

A secondary battery, battery technology, applied in the direction of secondary battery, secondary battery manufacturing, battery assembly machine, etc., can solve the problems of delay, electrode separator distortion, difficult to master and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

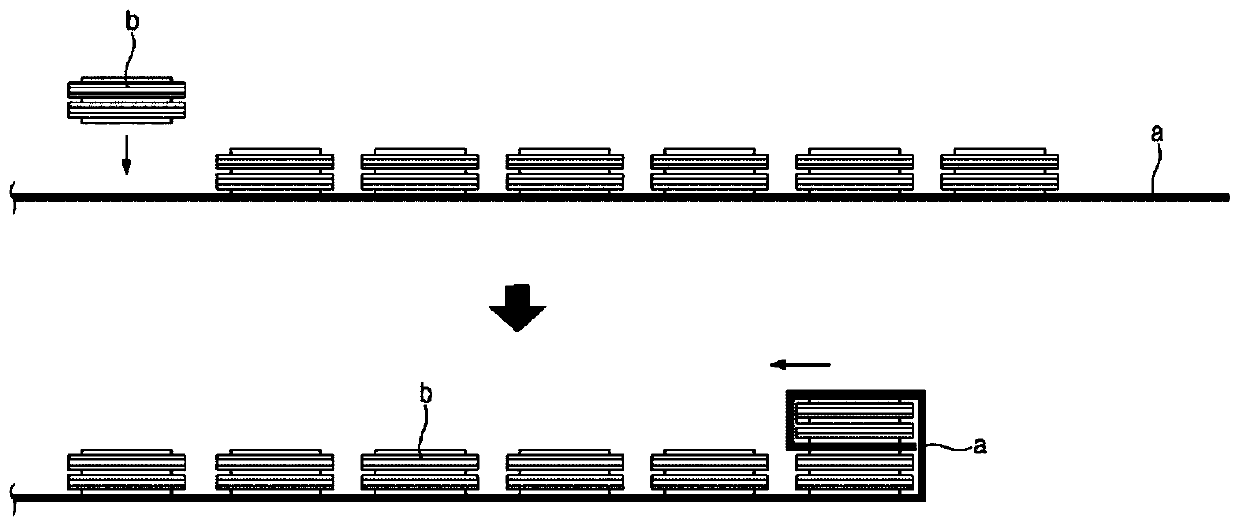

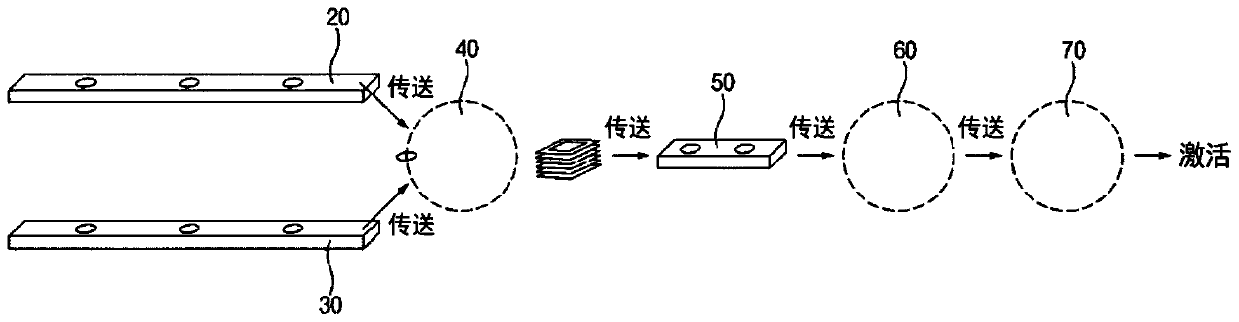

[0041] figure 2 is a process diagram showing the overall arrangement of the manufacturing system according to the present invention. refer to figure 2 , in the manufacturing system according to the present invention, the positive electrode battery production line 20 and the negative electrode battery production line 30 are arranged in parallel to each other, and then the stacking part 40, the welding part 50, the packaging part 60 and the injection liquid sealing part 70 are arranged in series, thereby performing continuous processing.

[0042] In the positive electrode battery production line 20 and the negative electrode battery production line 30, electrode bases for coating electrode slurry (positive electrode slurry and negative electrode slurry) on one surface of each current collector are continuously placed on the respective inlet sides. materials (positive electrode substrate and negative electrode substrate) to start processing. Positive and negative cells are ma...

Embodiment 2

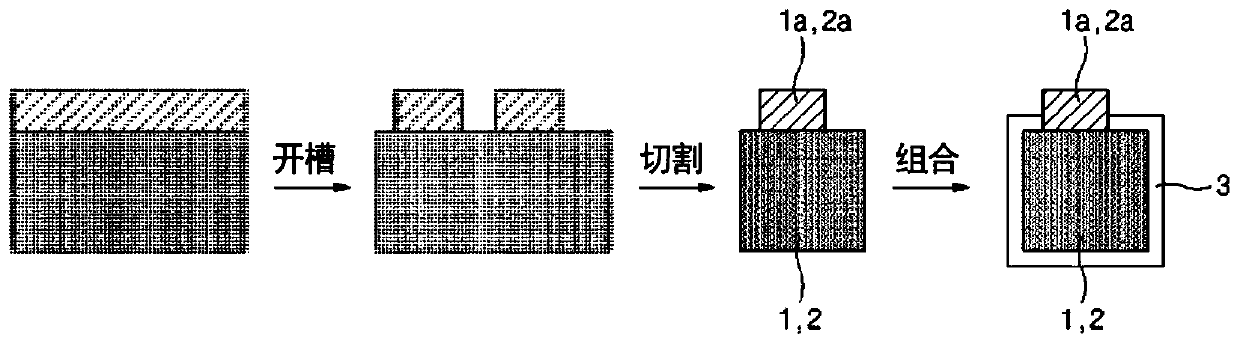

[0057] In the present invention, there is additionally provided a method for manufacturing a secondary battery to which the above-mentioned manufacturing system is applied. The manufacturing method according to this embodiment includes the step of alternately providing a positive electrode single cell and a negative electrode single cell on which a tab 1a is processed on one end of the positive electrode 1 and a separator is combined on one surface of the positive electrode 1 3. On the negative single cell, process a tab 2a on one end of the negative electrode 2 and assemble a separator on one surface of the negative electrode 2 . This step is performed by the positive electrode battery production line 20 and the negative electrode battery production line 30 .

[0058] In addition, a step of alternately stacking the positive and negative single cells to a predetermined layer by the stacking part 40 to form the stacked battery 10, and connecting the negative tabs to each other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com