Biomass charcoal organic planting soil

A technology of biomass charcoal and bio-organic fertilizer, applied in planting substrates, botanical equipment and methods, horticulture, etc., can solve the problems of pollution and high price, restore soil ecological environment, increase soil organic matter, degrade pesticide residues and The effect of organic pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

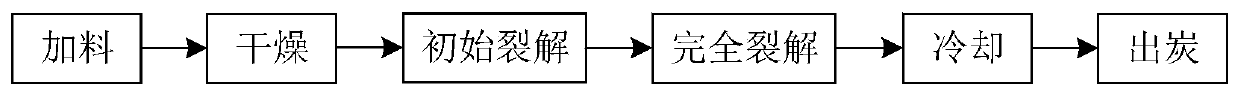

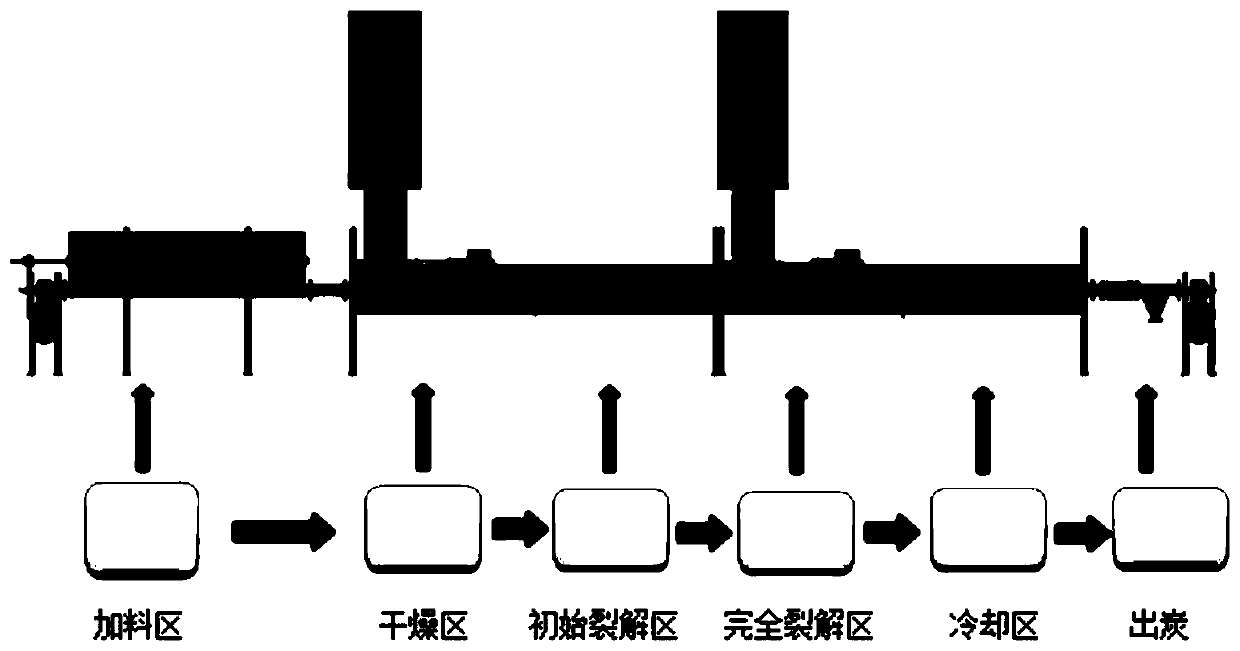

[0040] The preparation process of biochar in this example is similar to that of an assembly line. After the biomass raw material is put into the feeding area, it is sequentially dried, initially cracked, completely cracked and cooled, and these treatments are all automatically run in different areas of the equipment. For the preparation method that completes all steps of carbonization in one container, the preparation method not only has fast carbonization speed and high carbon production rate, but also can realize continuous carbon production.

[0041]It should be noted that the propeller in this embodiment should be understood as a component that can apply a directional boost force to the material. The specific structure of the propeller is not strictly limited on the premise of realizing the above functions. The propeller can be The material propeller may also be, for example, the screw propeller disclosed in the literature with the patent application number 201310339841.0. ...

Embodiment 1

[0056] A biochar organic planting soil, the biochar organic planting soil comprises the following components and parts by weight: 10 parts of biochar, 5 parts of red jade soil, 5 parts of soft wheat rice stone, 6 parts of vermiculite, 10 parts of coconut peat 2 parts, 2 parts of trace elements, 2 parts of bio-organic fertilizer.

[0057] Wherein, the preparation method of biochar is as follows:

[0058] Take the biomass raw material and put it into the feeding area, and pass through the drying area, initial cracking area, complete cracking area, and cooling area in sequence under the action of the propeller, and finally discharge the biomass charcoal from the discharge port;

[0059] The biomass raw material is crushed to a particle diameter of 5 cm in the feeding zone;

[0060] The speed of the propeller is 5 rpm, the time of the biomass raw material in the drying zone, the initial cracking zone, and the complete cracking zone is 15 seconds respectively, and the drying tempe...

Embodiment 2

[0063] A biochar organic planting soil, the biochar organic planting soil comprises the following components and parts by weight: 20 parts of biochar, 15 parts of red jade soil, 10 parts of soft wheat rice stone, 14 parts of vermiculite, 22 parts of coconut peat 3 parts, 3 parts of trace elements, 6 parts of bio-organic fertilizer.

[0064] Wherein, the preparation method of biochar is as follows:

[0065] Take the biomass raw material and put it into the feeding area, and pass through the drying area, initial cracking area, complete cracking area, and cooling area in sequence under the action of the propeller, and finally discharge the biomass charcoal from the discharge port;

[0066] The biomass raw material is pulverized in the feeding zone until the particle diameter does not exceed 5cm;

[0067] The speed of the propeller is 20 rpm, the time of the biomass raw material in the drying zone, the initial cracking zone, and the complete cracking zone is 100 seconds respectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com