A kind of waste wool fiber powder and its preparation method and application

A wool fiber and powder technology, applied in plant fibers, fiber cutting, fiber processing, etc., can solve the problems of wool fiber waste, different growth environments, differences in wool fiber length and thickness, and achieve the effect of improving environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

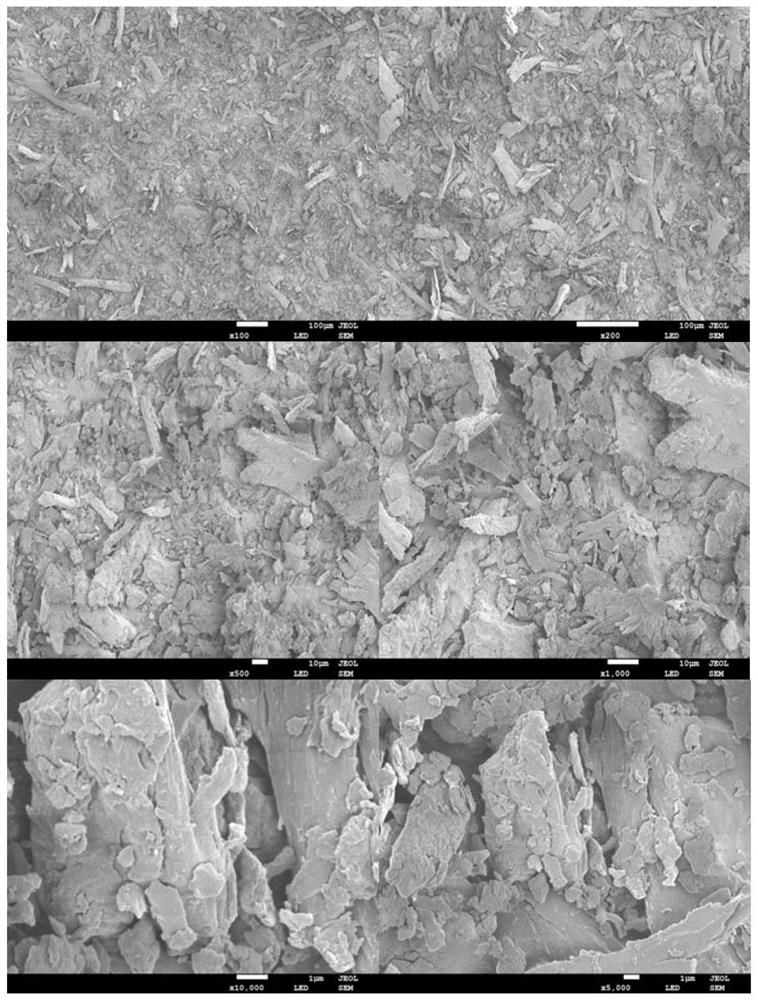

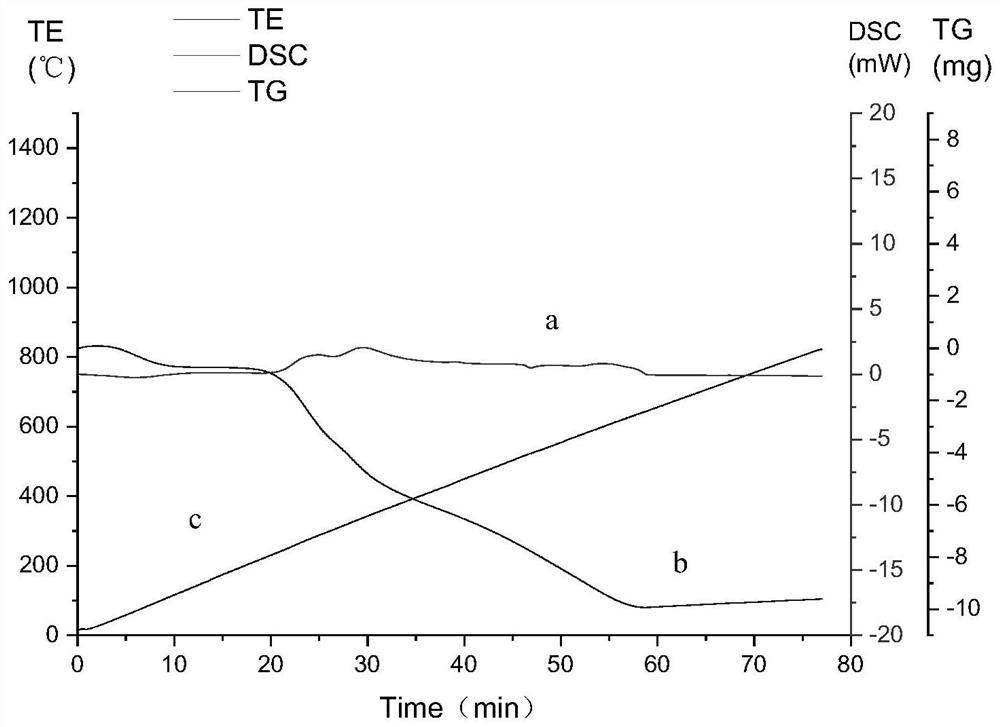

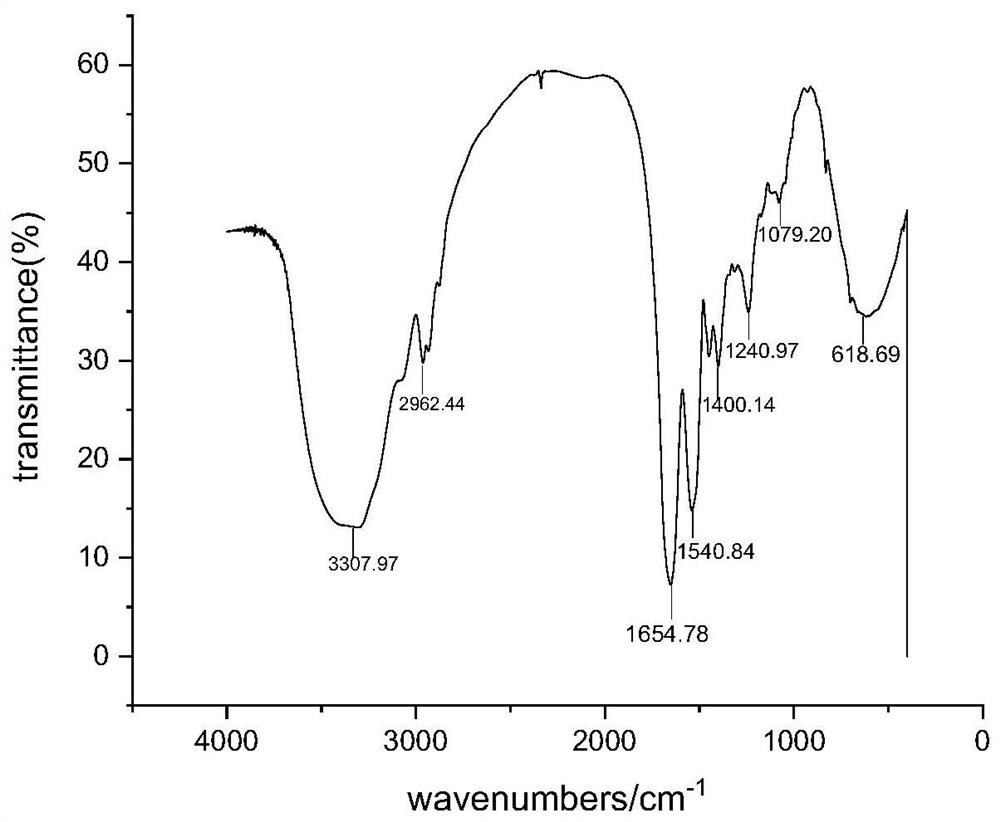

[0026] A preparation method of waste wool fiber powder, the preparation method is: cutting waste wool loose fibers to 4-6mm, using Emax high-energy ball mill to grind for 2 minutes → pause for 3 minutes → grind for 2 minutes → pause for 3 minutes → grind for 2 minutes as one grinding , the rotating speed is 1100r / min, after the product obtained from the first grinding is cooled, the second grinding is carried out the same as the first grinding, and the waste wool fiber powder with an average particle size of 27.40μm is ground, and the particle size is scanned by laser instrument test, the results are shown in Table 1, and the performance test results of the prepared waste wool fiber powder are shown in Figure 1-4 .

[0027] Table 1

[0028]

Embodiment 2

[0030] The application of the waste wool fiber powder prepared by embodiment 1 in weaving, the application method is as follows:

[0031] 120g / m 2 Cotton fabric pretreatment, desizing treatment in boiling water at 100°C, drying at 80°C;

[0032] The waste wool fiber powder prepared in Example 1 and distilled water were used to obtain a wool powder suspension at 25g / L;

[0033] Soak the pretreated cotton fabric in the wool powder suspension for 15 minutes at a bath ratio of 1:35;

[0034] The cotton fabric was subjected to five-dip and five-pass padding with a sample padding machine, and the excess rate was 65%, and it was dried at 120°C for 15 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com