A kind of self-lubricating addition type liquid silicone rubber and its preparation method and application

A liquid silicone rubber, self-lubricating technology, applied in the field of silicone rubber, which can solve problems such as low compression set

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

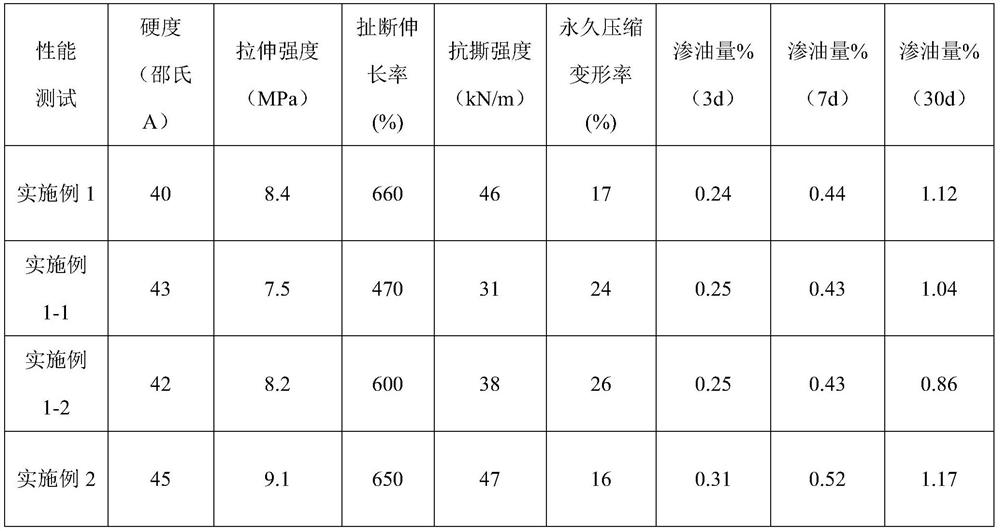

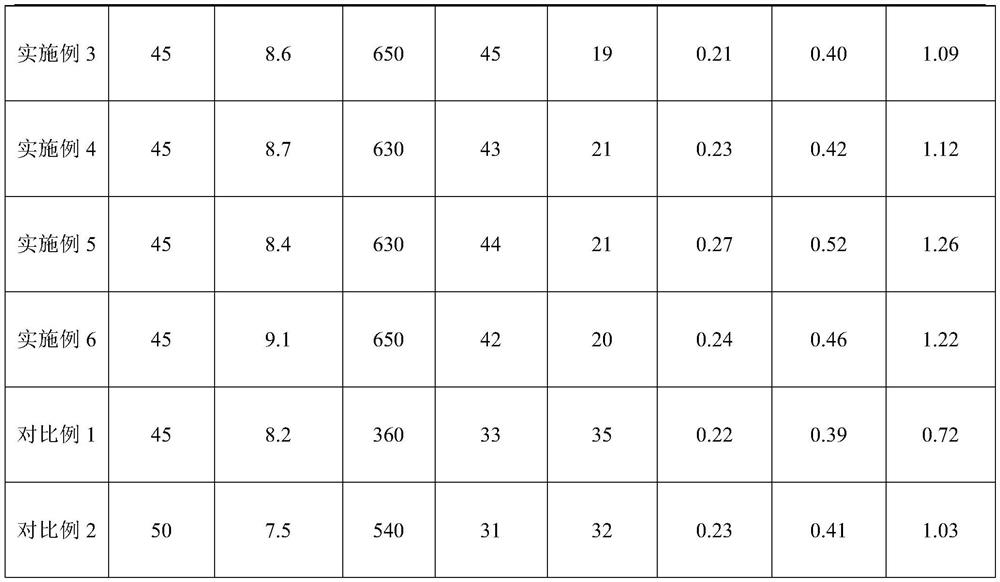

Examples

preparation example 1

[0043] In a kneader or planetary mixer, 42 parts by weight of vinyl-terminated polysiloxane with a viscosity of 60,000 mPa·s and an alkenyl content of 0.03 mmol / g, 2.8 parts of a viscosity of 200,000 mPa·s, and an alkenyl content of 0.8mmol / g side chain vinyl polysiloxane, 25 parts of BET specific surface area is 300m 2 / g of fumed silica and 7.05 parts of hexamethyldisilazane, 0.15 parts of tetramethyldivinylsilazane and 6.5 parts of deionized water, fully mixed under the protection of an inert atmosphere below 80 ° C for 1 ~2 hours, then heat up to 130~150°C and start vacuuming for 2~4 hours, keep the temperature at 150~170°C during vacuuming, then cool down to 110~140°C, add 16.5 parts of viscosity 20000mPa·s, vinyl content 0.035mmol / g terminal alkenyl polysiloxane, stir evenly to obtain liquid silicone rubber base rubber 1.

preparation example 2

[0045] In a kneader or planetary mixer, 40 parts by weight of methyl vinyl polysiloxane with a viscosity of 60000mPa·s and an alkenyl content of 0.03mmol / g, and 3 parts of a viscosity of 250000mPa·s, alkenyl Polyvinylpolysiloxane with a content of 0.9mmol / g, 27.5 parts of BET with a specific surface area of 400m 2 / g of fumed silica and 8 parts of hexamethyldisilazane, 0.5 parts of tetramethyldivinylsilazane and 4.5 parts of deionized water, fully mixed under the protection of an inert atmosphere below 80 °C for 1 ~2 hours, then heat up to 130~150°C and start vacuuming for 2~4 hours, keep the temperature at 150~170°C during vacuuming, then cool down to 110~140°C, add 17 parts of alkenyl The content is 0.030mmol / g methyl vinyl polysiloxane, and the liquid silicone rubber base rubber 2 is obtained by stirring evenly.

Embodiment 1

[0050] Preparation of component AB: 100 parts of base gum 1 above, 4.1 parts of terminal vinyl polysiloxane with a viscosity of 20000mPa·s and an alkenyl content of 0.035mmol / g, 7.2 parts of a viscosity of 1000mPa·s, parts of vinyl Side-chain vinyl polysiloxane with a group content of 0.12mmol / g, 3.0 parts of polysiloxane with a viscosity of 400mPa·s and an alkenyl content of 0.9mmol / g containing vinyl groups in both the terminal group and the side chain, 0.014 1 part Castel catalyst, 2.3 parts methyl phenyl silicone oil with a viscosity of 300mPa·s, stir and disperse in a planetary mixer for 30-40min, mix evenly and then vacuumize and defoam to obtain the self-lubricating low pressure variable liquid silicone rubber A component. The above 100 parts of base gum 1, 8.8 parts of vinyl polysiloxane with a viscosity of 20000mPa·s and vinyl polysiloxane with an alkenyl content of 0.035mmol / g, 3.5 parts of vinyl polysiloxane with a viscosity of 400mPa·s, vinyl polysiloxane 2.3 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com