A microchannel device and method for enhancing convective heat transfer based on magnetic force

A convective heat transfer and micro-channel technology, applied in the field of micro-channels, can solve the problems of ineffective heat transfer enhancement and limited contact area, and achieve the effect of strong convective heat transfer capability and enhanced convective heat transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

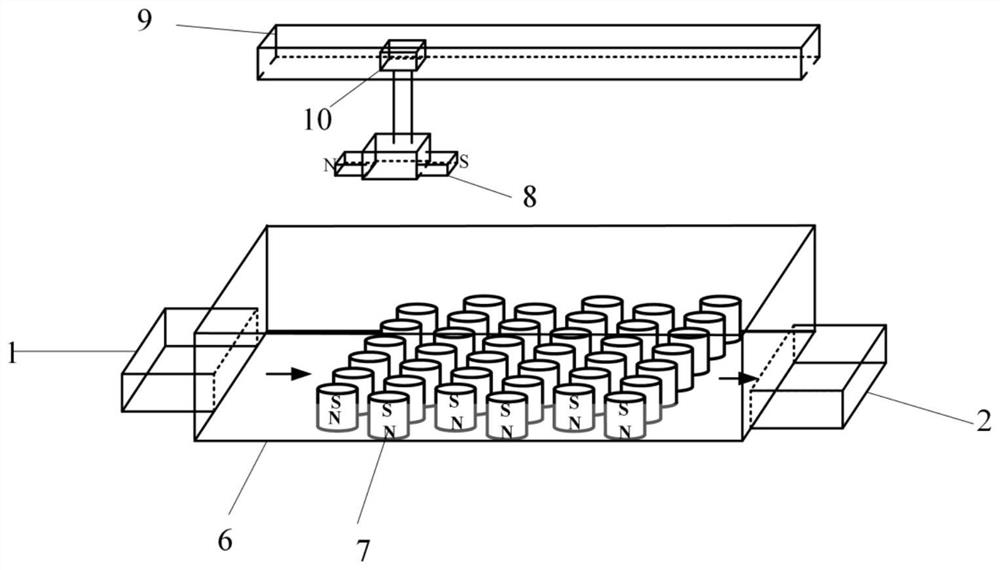

[0031] Embodiment 1: as figure 1 with 5 As shown, a microchannel device based on magnetic force-enhanced convective heat transfer includes a heat exchange box, and a number of rows of heat exchange microcolumns 7 are fixedly arranged on the heat exchange bottom plate 6 of the heat exchange box along the flow direction of the working fluid. The heat microcolumns 7 form microchannels, and the single heat exchange microcolumns 7 of the Nth row are located on the central axis of two adjacent heat exchange microcolumns 7 in the N-1th row, where N≥2; the top wall of the heat exchange box A chute 9 is provided on the central axis along the flow direction of the working fluid, and a slide block 10 is arranged in the chute 9. The bottom end of the slide block 10 is fixedly provided with a permanent magnet 8 and the permanent magnet 8 is located directly above the microchannel; the heat exchange box The body is arranged on the heat source 5;

[0032] The centers of both ends of the he...

Embodiment 2

[0038] Embodiment 2: The magnetic-based microchannel device for enhanced convective heat transfer in this embodiment is basically the same as in Embodiment 1, except that the distance between each row of adjacent heat transfer microcolumns 7 is 5 μm, and the heat transfer microcolumns The distance between adjacent rows of 7 is 5 μm, the diameter of the microcolumn is 3 μm, and the height of the microcolumn is 15 μm;

[0039] The heat exchange microcolumn 7 is a metal rubber microcolumn, and the outer wall of the metal rubber microcolumn is coated with Fe 3 o 4 Coating, the heat exchange bottom plate 6 of the heat exchange box is coated with a heat-conducting silicone grease layer;

[0040] The length of the heat exchange box is 100 μm, the width is 50 μm, the width of the permanent magnet 8 is 15 μm, and the length is 20 μm, and the distance between the bottom surface of the permanent magnet 8 and the top surface of the heat exchange microcolumn 7 is 20 μm;

[0041] The heat...

Embodiment 3

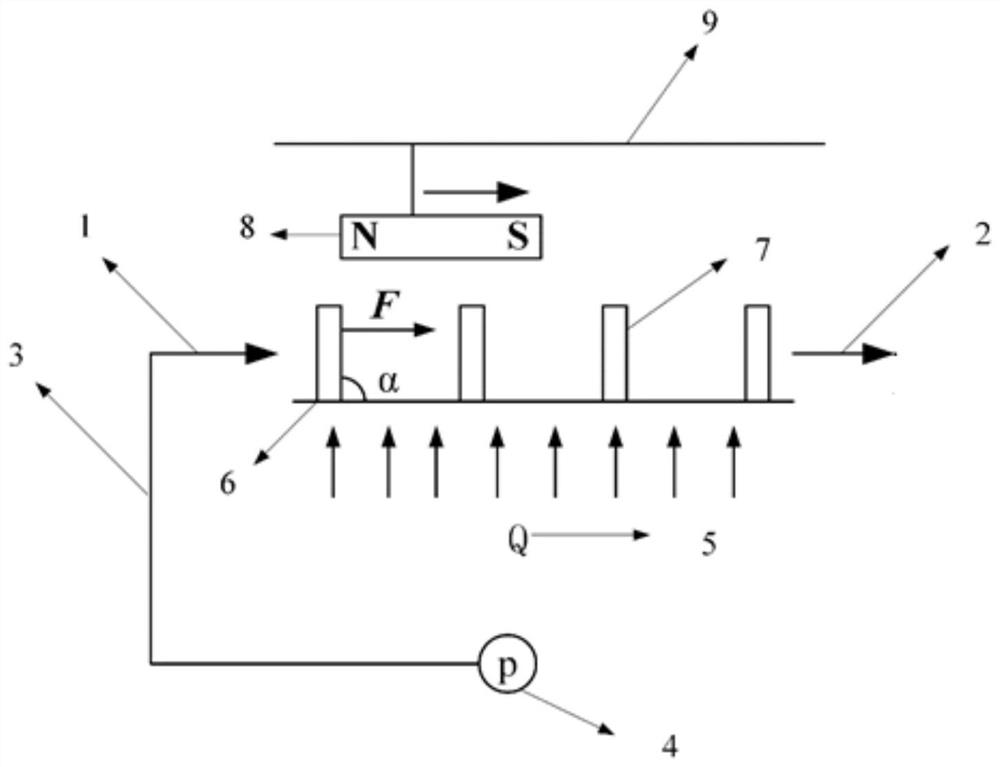

[0042] Embodiment 3: as Figure 1~5 As shown, the magnetic-based enhanced convective heat transfer method adopts the magnetic-based enhanced convective heat transfer microchannel device, and the specific steps are as follows:

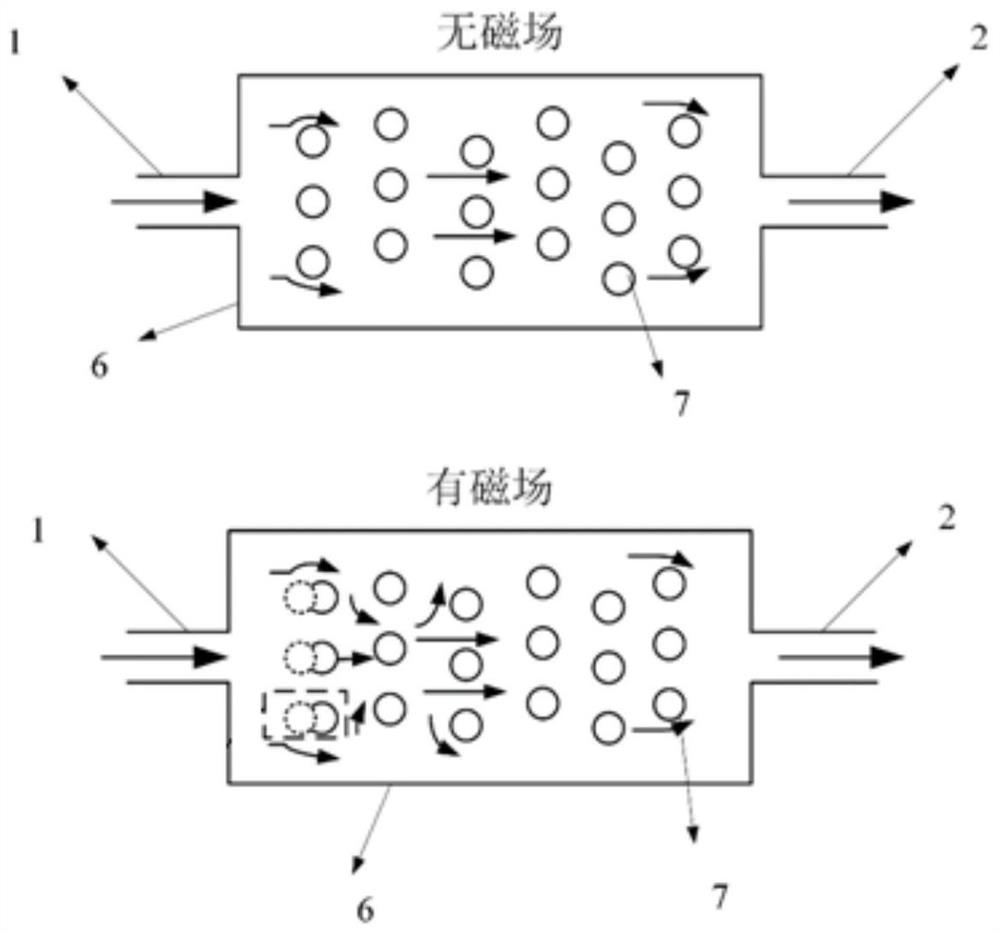

[0043](1) Slide the permanent magnet to the working fluid inlet end of the heat exchange box, pump the working fluid to be heat exchanged into the heat exchange box, and the working fluid to be heat exchanged flows into the microchannel formed by the heat exchange microcolumn, the microchannel The heat-exchanging micro-column is tilted under the magnetic force of the permanent magnet, and the flow of the working fluid to be heat-exchanged is blocked and chaotic, so that the contact area between the working fluid to be heat-exchanged and the heat-exchanging micro-column increases to enhance the heat exchange effect;

[0044] (2) With the flow of the working fluid to be heat exchanged, the permanent magnet slides synchronously along the direction of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com