Anti-scouring and high-persistence pesticide microsphere and preparation method thereof

A pesticide microsphere, anti-scour technology, applied in the directions of microsphere preparation, botanical equipment and method, microcapsule preparation, etc., can solve problems such as increasing pesticide retention, achieve wide universality, avoid groundwater pollution, and facilitate pesticide utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 115

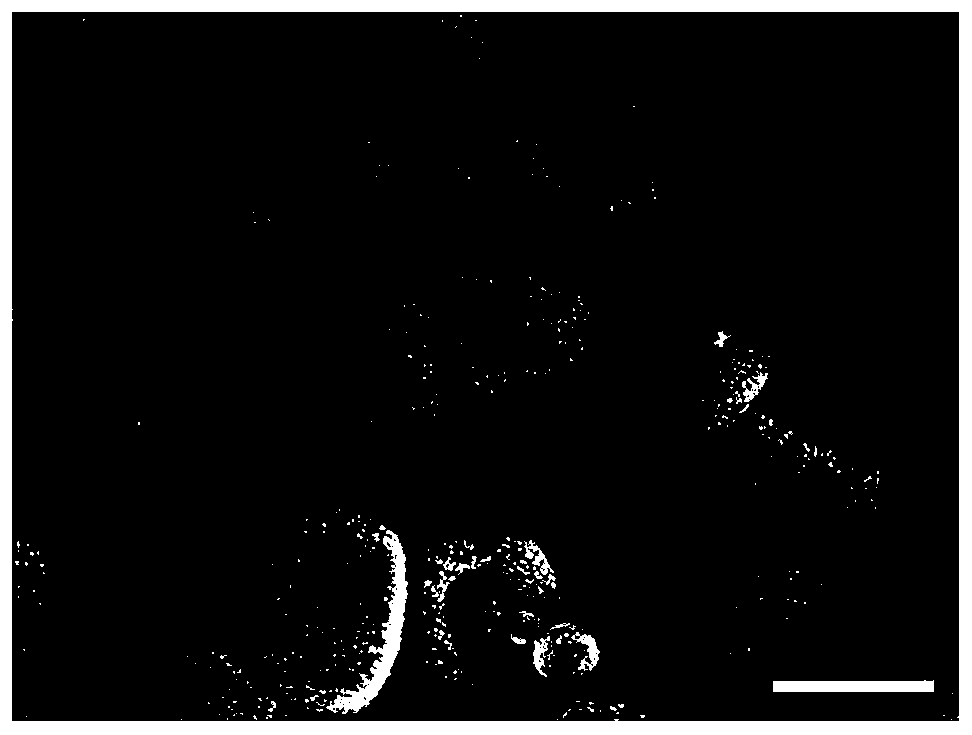

[0035] Example 1 15% Difenoconazole Pesticide Microspheres

[0036]

[0037] According to the formula of Example 1, 15% difenoconazole microspheres were prepared, wherein 1 micron polystyrene microspheres were prepared by conventional soap-free emulsion polymerization, and other agents were purchased from Aladdin Biochemical Technology Co., Ltd. The preparation scheme is as follows:

[0038] a. Add 0.25g of decane chloride and 0.15g of 1 micron polystyrene microspheres into 90ml of 0.25% (w / v) sodium lauryl sulfate solution for ultrasonic dispersion and continue magnetic stirring at 40°C for 16 hours (300-400 rpm);

[0039] b. Add 4.06g styrene, 2.73g stilbene, 0.12g azobisisobutyronitrile, 0.015g 9-vinyl anthracene, 0.45g difenoconazole to 30ml of 0.25% (w / v) decane Ultrasonic dispersion in dialkyl sodium sulfate solution to obtain oil-in-water emulsion. The resulting emulsion was added dropwise to the solution prepared in step a. After magnetic stirring at 40° C. for ...

Embodiment 2

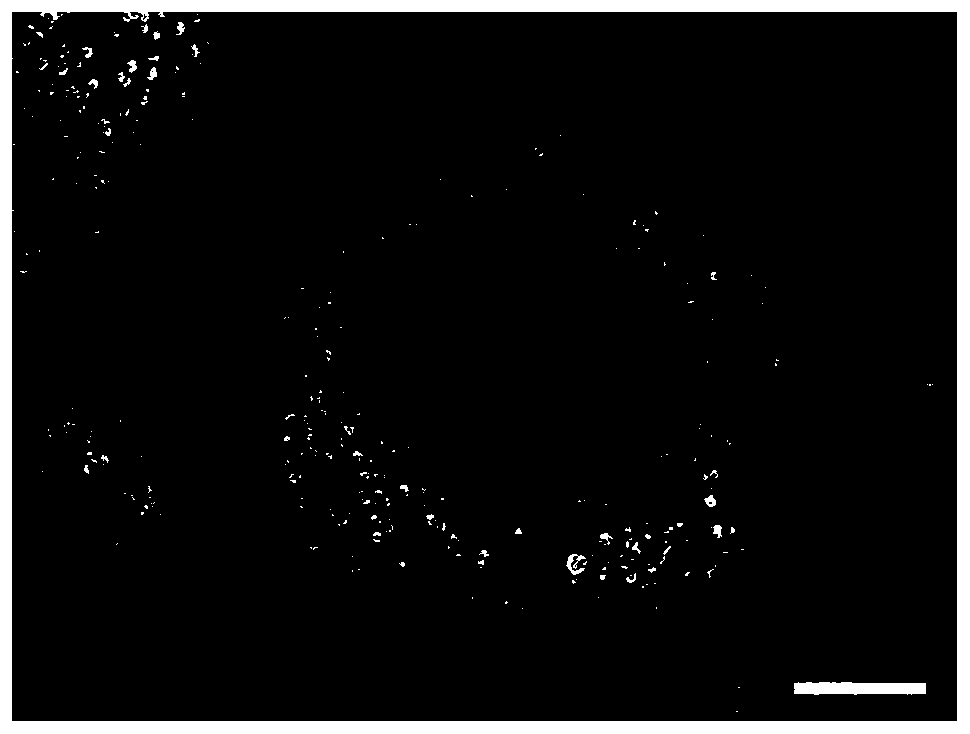

[0057] Example 2 10% Difenoconazole Pesticide Microspheres

[0058]

[0059] According to the formula in Example 2, 10% difenoconazole pesticide microspheres were prepared, wherein 1 micron polystyrene microspheres were prepared by conventional soap-free emulsion polymerization, and other agents were purchased from Aladdin Biochemical Technology Co., Ltd. The preparation scheme is as follows:

[0060] a. Add 0.25g of decane chloride and 0.15g of 1 micron polystyrene microspheres into 90ml of 0.25% (w / v) sodium lauryl sulfate solution for ultrasonic dispersion and continue magnetic stirring at 40°C for 16 hours (300-400 rpm);

[0061] b. Add 4.06g styrene, 2.73g stilbene, 0.12g azobisisobutyronitrile, 0.015g 9-vinyl anthracene, 0.30g difenoconazole to 30ml of 0.25% (w / v) decanoline Ultrasonic dispersion in dialkyl sodium sulfate solution to obtain oil-in-water emulsion. The resulting emulsion was added dropwise to the solution prepared in step a. After magnetic stirring ...

Embodiment 3

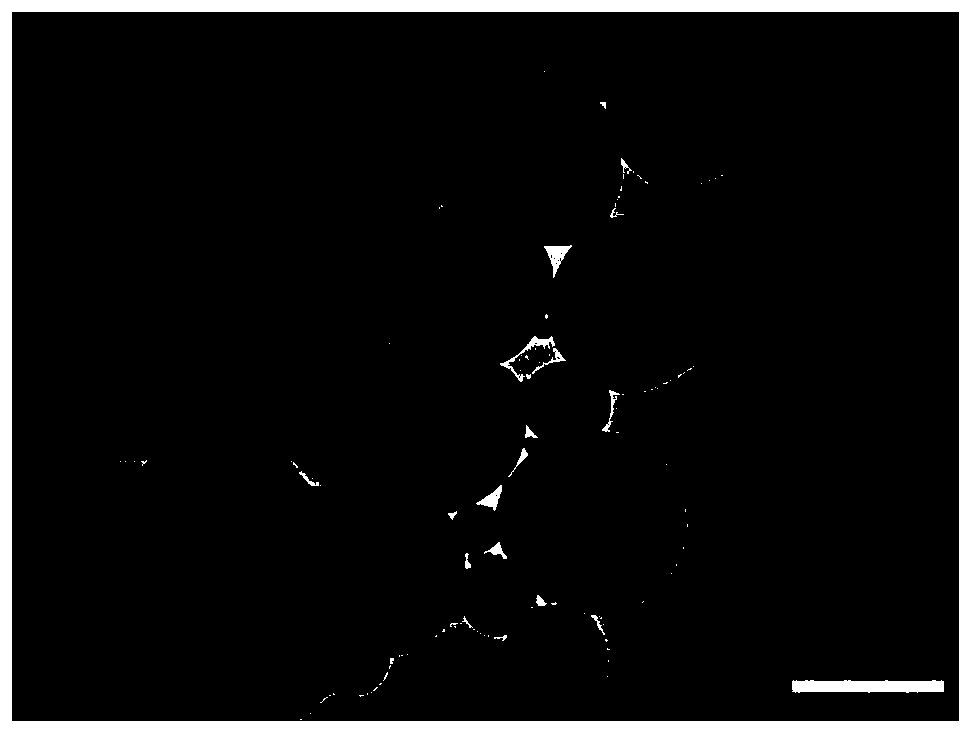

[0069] Example 3 5% Difenoconazole Pesticide Microspheres

[0070]

[0071] According to the formula in Example 3, 5% difenoconazole pesticide microspheres were prepared, wherein 1 micron polystyrene microspheres were prepared by conventional soap-free emulsion polymerization, and other agents were purchased from Aladdin Biochemical Technology Co., Ltd. The preparation scheme is as follows:

[0072] a. Add 0.25g of decane chloride and 0.15g of 1 micron polystyrene microspheres into 90ml of 0.25% (w / v) sodium lauryl sulfate solution for ultrasonic dispersion and continue magnetic stirring at 40°C for 16 hours (300-400 rpm);

[0073] b. Add 4.06g styrene, 2.73g stilbene, 0.12g azobisisobutyronitrile, 0.015g 9-vinyl anthracene, 0.15g difenoconazole to 30ml of 0.25% (w / v) ten Ultrasonic dispersion in dialkyl sodium sulfate solution to obtain oil-in-water emulsion. The resulting emulsion was added dropwise to the solution prepared in step a. After magnetic stirring at 40° C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com