A kind of compound two-way humectant, its preparation method and application

A humectant and application technology, applied in the field of tobacco processing, can solve the problems of inability to form a protective layer on the surface of cut tobacco, adverse effects on the taste of cigarettes, poor stability, etc., and achieve the effects of achieving sensory comfort, reducing sensitivity, and improving bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Accurately weigh 2g Polygonatum polysaccharide and dissolve it in 48g distilled water to prepare a 4wt% solution, adjust the pH of the solution to 5.0, add complex cellulase to 0.1wt% of Polygonatum polysaccharide mass, and enzymatically hydrolyze at 50°C for 2h. The enzyme was inactivated in a boiling water bath, and then centrifuged at 8000 rpm for 20 minutes to remove the precipitate to obtain the enzymatic hydrolyzate of Polygonatum polysaccharide complex cellulase;

[0047] (2) Add 40g of distilled water to Polygonatum Polysaccharide Enzymolyzate, mix well;

[0048] (3) Add 10 g of sucrose fatty acid ester, stir in a water bath at 80° C., and mix evenly to obtain a composite two-way moisturizer.

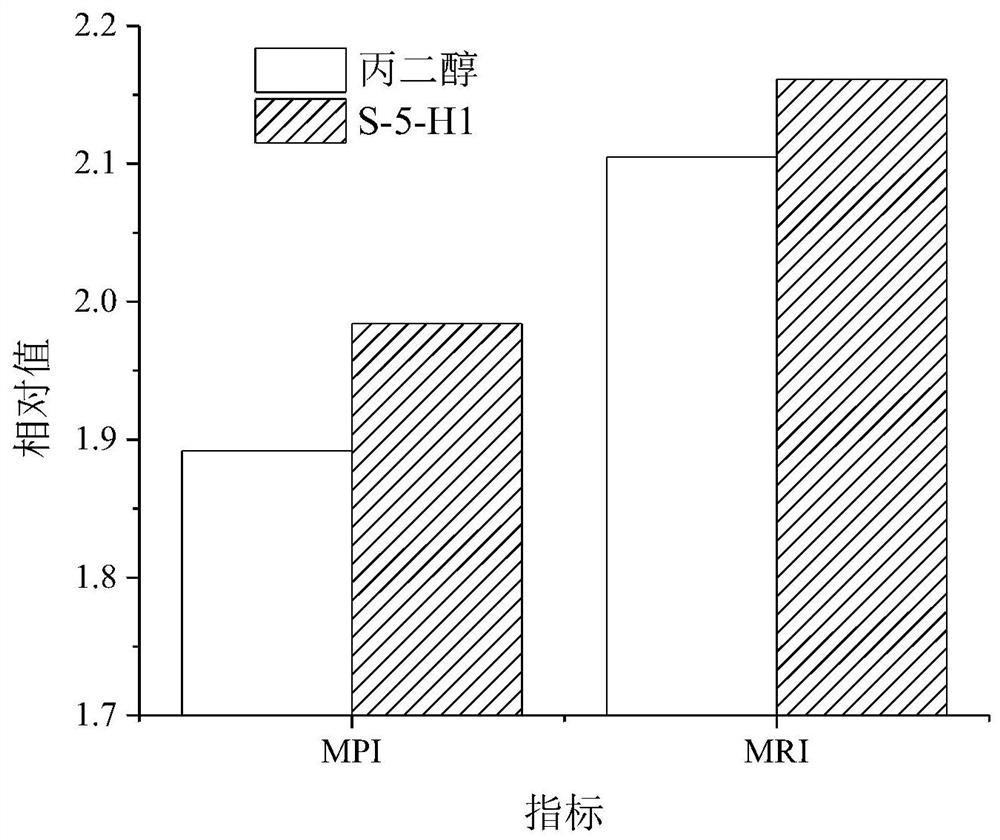

[0049] The composite two-way humectant obtained is evenly sprayed into shredded tobacco, so that its addition amount is 2wt% / 0.4wt% (sucrose fatty acid ester / polysaccharide polysaccharide complex cellulase hydrolyzate) of shredded tobacco to add an equivalent amount o...

Embodiment 2

[0053] (1) Accurately weigh 2g Polygonatum polysaccharide and dissolve it in 48g distilled water to prepare a 4wt% solution, adjust the pH of the solution to 5.0, add complex cellulase to 1.0wt% of Polygonatum polysaccharide mass, and enzymatically hydrolyze at 50°C for 3h. Inactivate the enzyme in a boiling water bath, then centrifuge at 8000 rpm for 20 minutes to remove the precipitate, and obtain the enzymatic hydrolyzate of polygonatum polysaccharide;

[0054] (2) add 45g distilled water to Polygonatum Polysaccharide Enzymolyzate;

[0055] (3) Add 5 g of sucrose fatty acid ester, stir in a water bath at 80° C., and mix evenly to obtain 100 g of a composite two-way moisturizer.

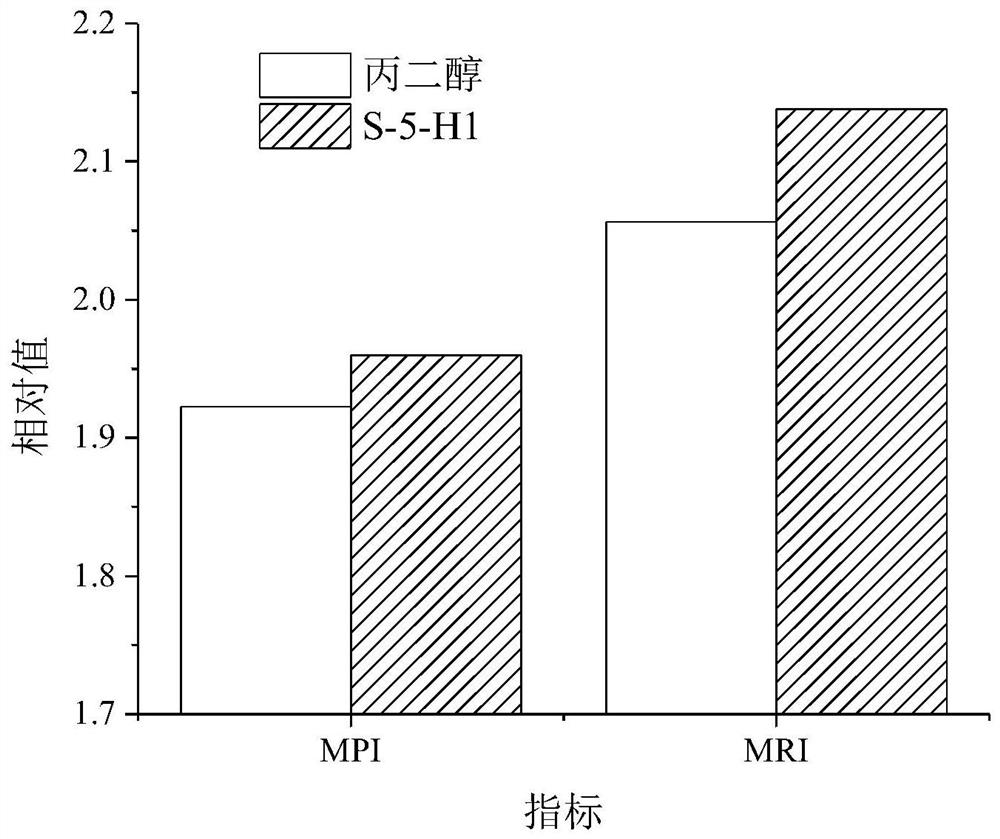

[0056] Composite two-way humectant is sprayed in shredded tobacco, and its addition is 1wt% / 0.4wt% (sucrose fatty acid ester / polysaccharide polysaccharide complex cellulase hydrolyzate of sucrose fatty acid) of shredded tobacco quality, to add an equal amount of propylene glycol (i.e. 1.4 wt%) shr...

Embodiment 3

[0060] In Example 2, the added amount of composite two-way humectant is 1wt% / 0.4wt% (sucrose fatty acid ester / Polygonatum polysaccharide complex cellulase hydrolyzate) of shredded tobacco to carry out sensory evaluation test, to add an equal amount The shredded tobacco of propylene glycol is used as a contrast, and is evaluated with reference to "YCT 138-1998 Tobacco and Tobacco Products Sensory Evaluation Method", and the results are as follows:

[0061]

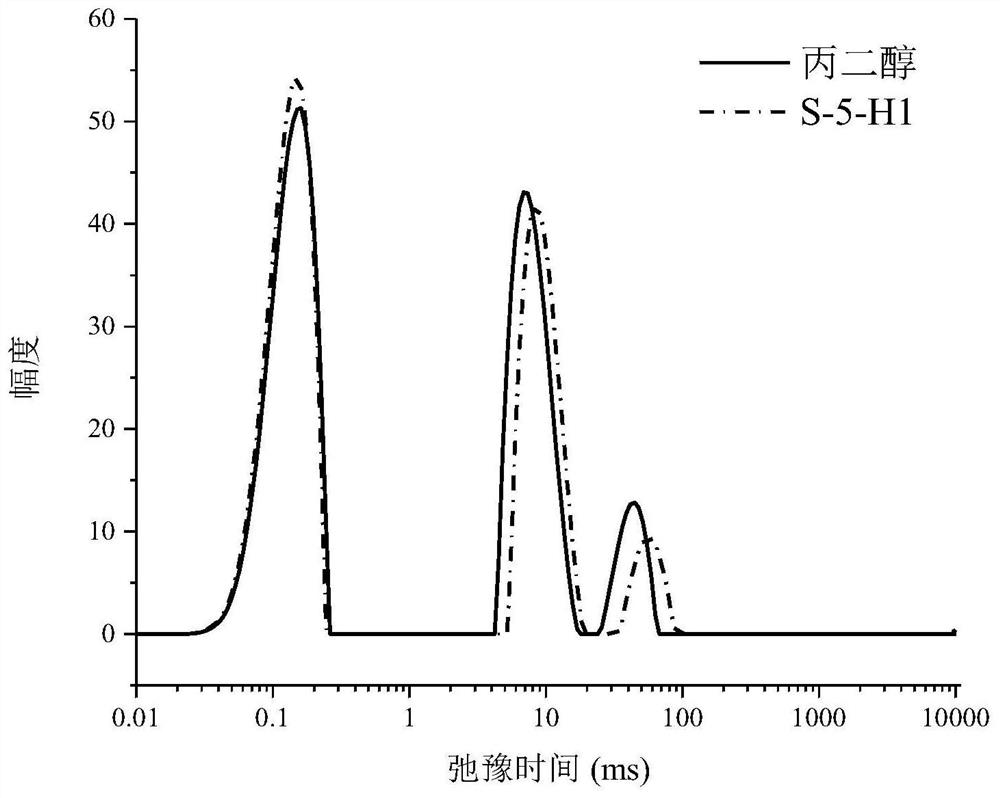

[0062] The results showed that compared with the control sample, the shredded tobacco added with compound humectant did not improve significantly in miscellaneous gas and irritation, but the aroma texture was improved, the smoke was softer and more delicate, the coordination was slightly enhanced, and the aftertaste was cleaner comfortable. Overall sensory quality was improved compared to the control. This shows that the compound humectant of the present invention not only has the effects of high-humidity moisture-proof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com