A kind of waterproof and antistatic children's clothing fabric and its production method

A production method and anti-static technology, applied in the field of fabrics, can solve the problems of not being able to directly use children's clothing design and children, and achieve the effects of strong waterproof ability, preventing heat evaporation, and maintaining comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

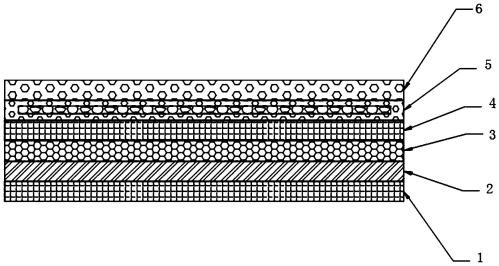

Image

Examples

Embodiment 1

[0072] Described antistatic agent is made from the raw material of following mass parts:

[0073] Distilled water 50g, polyurethane 5g, cellulose 1g, conductive mica powder 1g, water-absorbing resin 5g, metal fiber 2g, carbon fiber 5g, mica powder 1g, polyvinyl alcohol 2g, polysulfur nitride 1g, rubber 2g, softener 10g and penetrating agent 10g.

[0074] Wherein, the preparation of this antistatic agent comprises the following steps:

[0075] According to the above-mentioned mass parts, take each raw material required for the cotton cloth for keeping warm and antibacterial;

[0076] Mix 5g of polyurethane, 1g of cellulose, 1g of conductive mica powder, 5g of water-absorbing resin, 2g of metal fiber, 5g of carbon fiber, 1g of mica powder, 2g of polyvinyl alcohol and 1g of polysulfur nitride, and stir to make a mixture one;

[0077] Pour 50 g of weighed distilled water into mixture 1, stir evenly, and decoct. After the decoction is completed, filter to make mixture 2;

[007...

Embodiment 2

[0081] Described antistatic agent is made from the raw material of following mass parts:

[0082] Distilled water 150g, polyurethane 15g, cellulose 5g, conductive mica powder 5g, water absorbent resin 12g, metal fiber 12g, carbon fiber 16g, mica powder 5g, polyvinyl alcohol 18g, polysulfur nitride 20g, rubber 20g, softener 25g and penetrating agent 50g.

[0083] Wherein, the preparation of this antistatic agent comprises the following steps:

[0084] According to the above-mentioned mass parts, take each raw material required for the cotton cloth for keeping warm and antibacterial;

[0085] Mix 15g of polyurethane, 5g of cellulose, 5g of conductive mica powder, 12g of water-absorbing resin, 12g of metal fiber, 16g of carbon fiber, 5g of mica powder, 18g of polyvinyl alcohol and 20g of polysulfur nitride, and stir to make a mixture one;

[0086] Pour 150 g of weighed distilled water into mixture 1, stir evenly, decoct, and filter to make mixture 2 after decoction is complete...

Embodiment 3

[0090] Described antistatic agent is made from the raw material of following mass parts:

[0091] Distilled water 80g, polyurethane 8g, cellulose 2.3g, conductive mica powder 2.3g, water-absorbing resin 7.3g, metal fiber 5.3g, carbon fiber 8g, mica powder 2.3g, polyvinyl alcohol 7.3g, polysulfur nitride 7.3g, rubber 8g , softening agent 15g and penetrating agent 23.3g.

[0092] Wherein, the preparation of this antistatic agent comprises the following steps:

[0093] According to the above-mentioned mass parts, take each raw material required for the cotton cloth for keeping warm and antibacterial;

[0094] Mix 8g of polyurethane, 2.3g of cellulose, 2.3g of conductive mica powder, 7.3g of water-absorbing resin, 5.3g of metal fiber, 8g of carbon fiber, 2.3g of mica powder, 7.3g of polyvinyl alcohol and 7.3g of polysulfur nitride , and stir evenly to make mixture 1;

[0095] Pour 80 g of weighed distilled water into mixture 1, stir evenly, decoct, and filter to make mixture 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com