Method for preparing slow-digestion functional extruded rice product

A technology of rice products and slow digestion, applied in the direction of food science, etc., can solve the problems of general public acceptance and fast rice digestion rate, and achieve the effects of convenient extraction process, high product quality uniformity, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

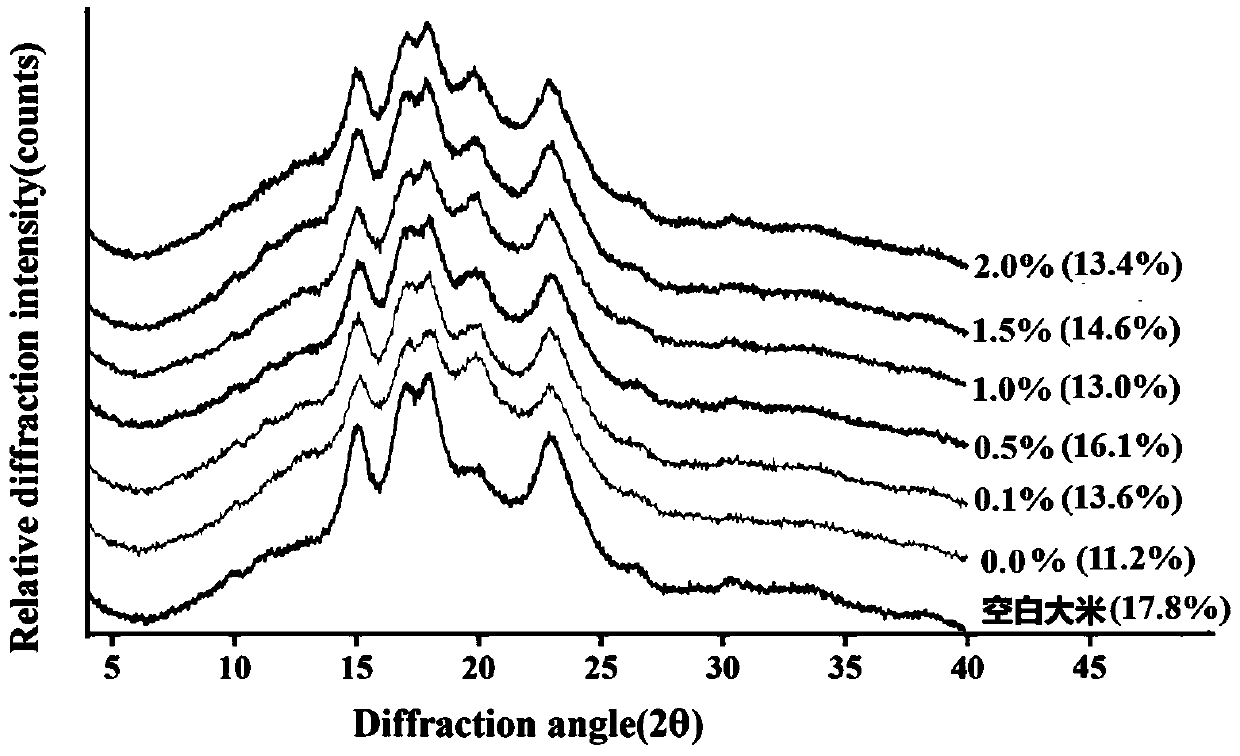

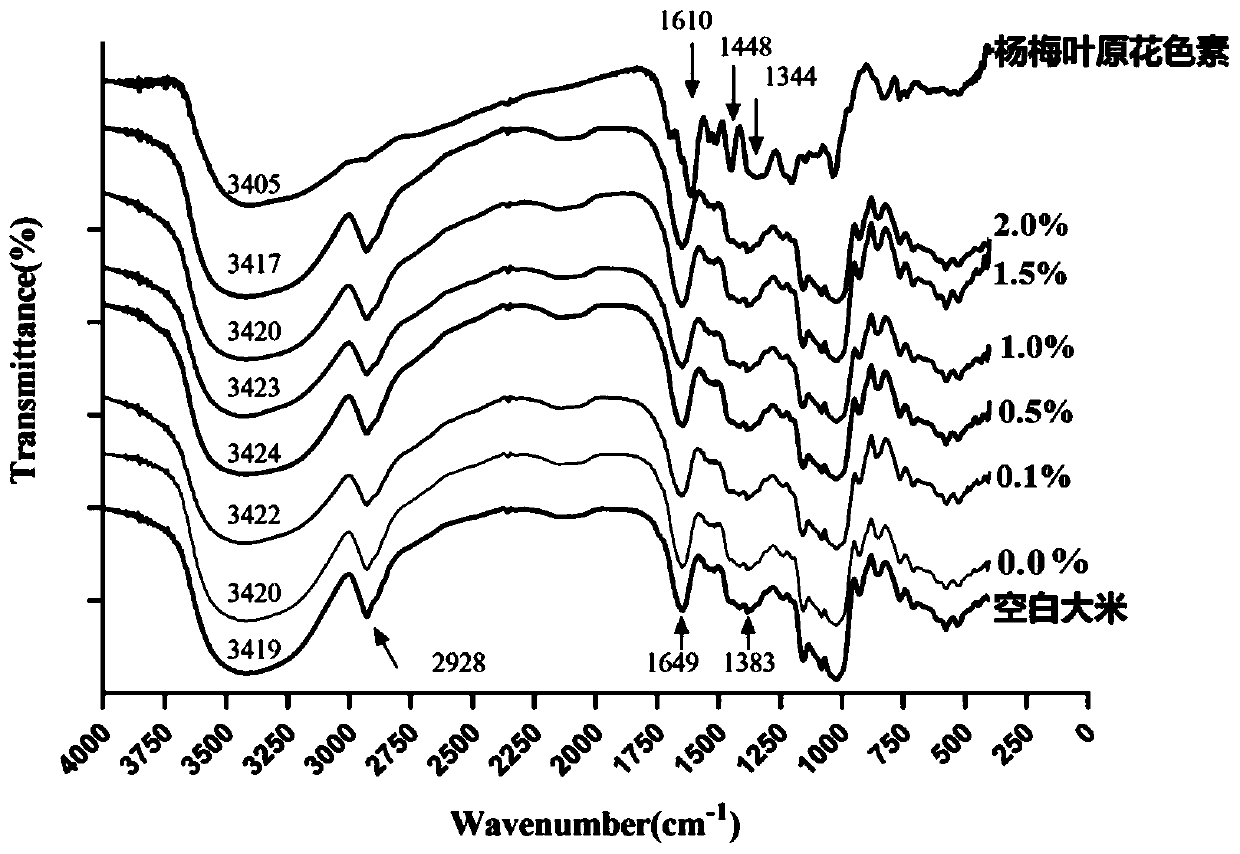

[0033] Example 1: Preparation of extruded rice products compounded with different concentrations of red bayberry leaf proanthocyanidins

[0034] S1. Mixing: crush the rice and pass through a 100-mesh sieve. Add broken rice in the mixing device, and take the broken rice as the benchmark amount, respectively add 0, 0.1%, 0.5%, 1.0%, 1.5% water of bayberry leaf proanthocyanidin and 25% weight ratio, mix and stir The rotation speed of the device is set at 100r / min, and the mixing time is 15min. The mixture is fully mixed in the mixing device to form a mixed raw material.

[0035] S2. Extrusion molding: Send the mixed raw materials into the twin-screw extrusion device, set the twin-screw speed of the twin-screw extrusion device to 70r / min, perform five-stage heating, set the first-stage temperature to 55°C, and the second-stage temperature to 60°C ℃, the third-level temperature is 65°C, the fourth-level temperature is 68°C, and the fifth-level temperature is 55°C. A twin-screw ex...

Embodiment 2

[0065] S1. Mixing: crush the rice and pass through a 60-mesh sieve. Add broken rice in the mixing device, and take the broken rice as the benchmark amount, add 1.5% by weight of bayberry leaf proanthocyanidins and 20% by weight of water, set the rotating speed of the mixing device to 110r / min, and mix for 25min. Mix thoroughly in a mixing device to form a mixed material.

[0066] S2. Extrusion molding: Send the mixed raw materials into the twin-screw extrusion device, set the twin-screw speed of the twin-screw extrusion device to 60r / min, perform five-stage heating, set the first-stage temperature to 60°C, and the second-stage temperature to 65°C ℃, the third-level temperature is 62°C, the fourth-level temperature is 65°C, and the fifth-level temperature is 60°C. A twin-screw extruder is set to prepare a diameter of 3mm and a length of extruded rice semi-finished product of 6mm.

[0067] S3, drying:

[0068] S3a, hot air drying: set the drying temperature of the hot air dry...

Embodiment 3

[0074] S1. Mixing: crush the rice and pass through a 100-mesh sieve. Add broken rice in the mixing device, and take the broken rice as the benchmark amount, add 0.5% by weight of bayberry leaf proanthocyanidins and 30% by weight of water, set the speed of the mixing device to 120r / min, and mix for 15min. Mix thoroughly in a mixing device to form a mixed material.

[0075] S2. Extrusion molding: Send the mixed raw materials into the twin-screw extrusion device, set the twin-screw speed of the twin-screw extrusion device to 115r / min, perform five-stage heating, set the first-stage temperature to 55°C, and the second-stage temperature to 60°C ℃, the third-level temperature is 68°C, the fourth-level temperature is 68°C, and the fifth-level temperature is 55°C. A twin-screw extruder is set to prepare a diameter of 2mm and a length of extruded rice semi-finished product of 4mm.

[0076] S3, drying:

[0077] S3a, hot air drying: set the drying temperature of the hot air drying dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com