Ru/NPC-CoxO based hydrogen production catalyst and preparation method

A catalyst, sodium borohydride technology, applied in the field of hydrogen energy, can solve the problems of difficult large-scale industrial production and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

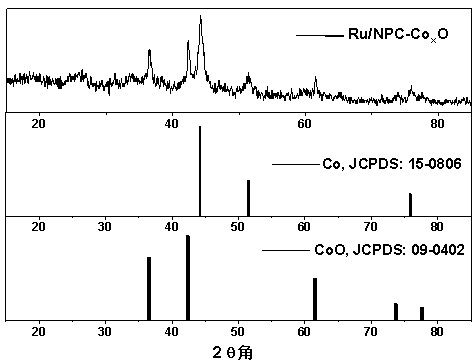

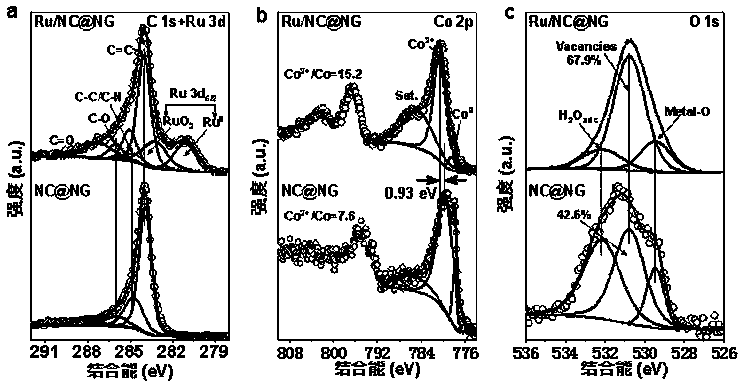

[0021] One, embodiment 1: prepare Ru / NPC-Co according to the following steps x O-800℃ composite material,

[0022] (1) Synthesis of ZIF8: In the process of synthesizing ZIF8, Zn(NO 3 ) 2 ·6H 2 O (3mmol, 30 mL) methanol solution and 2-methylimidazole (12mmol mg, 10mL) methanol solution. Then, 2-methylimidazole methanol solution was added to zinc nitrate methanol solution to form a mixed solution, aged at room temperature for 24 hours, and the white precipitate was collected by centrifugation, washed 3 times with methanol, and collected by centrifugation after each washing.

[0023] (2) Synthesis of ZIF-8@ZIF-67: ZIF-8 (80 mg) was ultrasonically dispersed in methanol (10 mL) for 30 min, stirred for 20 min and injected into Co(NO 3 )·6H 2 O (177mg, 3mL) in methanol and 2-methylimidazole (895mg, 3mL) in methanol. After stirring for 5 minutes, it was transferred to an autoclave and kept at 100 °C for 12 h.

[0024] (3) Synthesis of NPC-Co x O: Weigh 600mg of ZIF-8@ZIF-67 an...

Embodiment 2

[0038] Two, embodiment 2: prepare Ru / NPC-CoxO-700 ℃ composite material according to the following steps,

[0039] (1) Synthesis of ZIF-8: In the process of synthesizing ZIF-8, Zn(NO 3 ) 2 ·6H 2 O (3mmol, 30mL) methanol solution and 2-methylimidazole (12mmol mg, 10mL) methanol solution. Then, 2-methylimidazole methanol solution was added to zinc nitrate methanol solution to form a mixed solution, aged at room temperature for 24 hours, and the white precipitate was collected by centrifugation, washed 3 times with methanol, and collected by centrifugation after each washing.

[0040] (2) Synthesis of ZIF-8@ZIF-67: ZIF-8 (80 mg) was ultrasonically dispersed in methanol (10 mL) for 30 min, stirred for 20 min and injected into Co(NO 3 )·6H 2 O (177mg, 3mL) in methanol and 2-methylimidazole (895mg, 3mL) in methanol. After stirring for 5 minutes, it was transferred to an autoclave and kept at 100 °C for 12 h.

[0041] (3) Synthesis of NPC-Co x O: Weigh 600mg of ZIF-8@ZIF-67 and...

Embodiment 3

[0044] Three, embodiment 3: prepare Ru / NPC-Co according to the following steps x O-900°C composite material,

[0045] (1) Synthesis of ZIF-8: In the process of synthesizing ZIF-8, Zn(NO 3 ) 2 ·6H 2 O (3mmol, 30mL) methanol solution and 2-methylimidazole (12mmol mg, 10mL) methanol solution. Then, 2-methylimidazole methanol solution was added to zinc nitrate methanol solution to form a mixed solution, aged at room temperature for 24 hours, and the white precipitate was collected by centrifugation, washed 3 times with methanol, and collected by centrifugation after each washing.

[0046] (2) Synthesis of ZIF-8@ZIF-67: ZIF-8 (80 mg) was ultrasonically dispersed in methanol (10 mL) for 30 min, stirred for 20 min and injected into Co(NO 3 )·6H 2 O (177mg, 3mL) in methanol and 2-methylimidazole (895mg, 3mL) in methanol. After stirring for 5 minutes, it was transferred to an autoclave and kept at 100 °C for 12 h.

[0047] (3) Synthesis of NPC-Co x O: Weigh 600mg of ZIF-8@ZIF-6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com