Coaxial cable end tin coating device and tin coating method

A coaxial cable and tin-scraping technology, which is applied in the direction of line/collector parts, coatings, circuits, etc., can solve the problems of low soldering efficiency, difficult to guarantee welding quality, high welding precision requirements, etc., and achieve uniform tin coating , Mechanism simplification and high efficiency, and the effect of reducing the setting of the handling mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

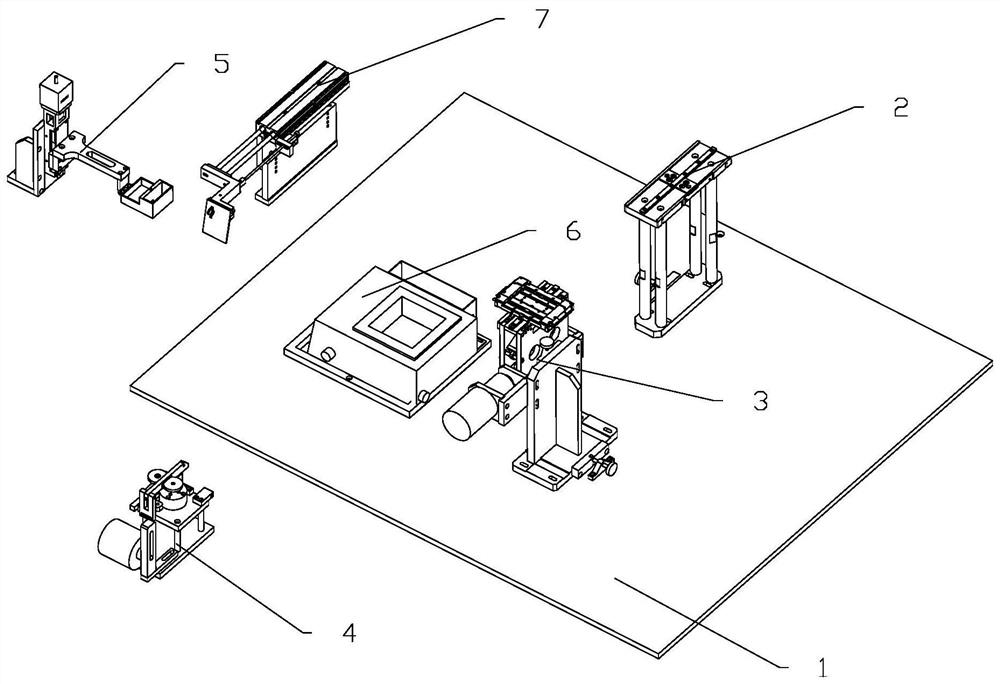

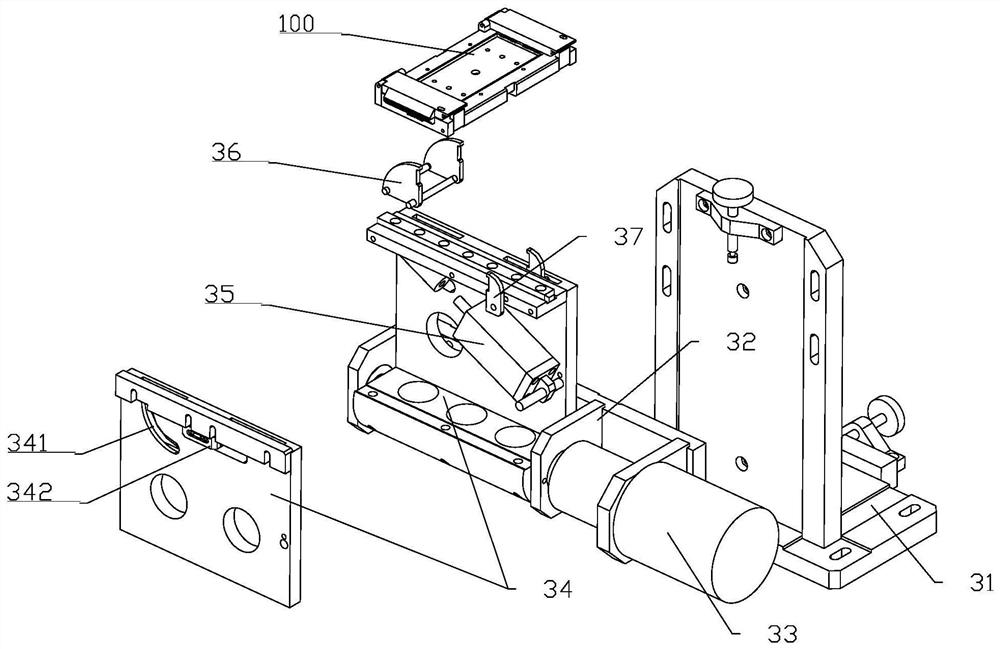

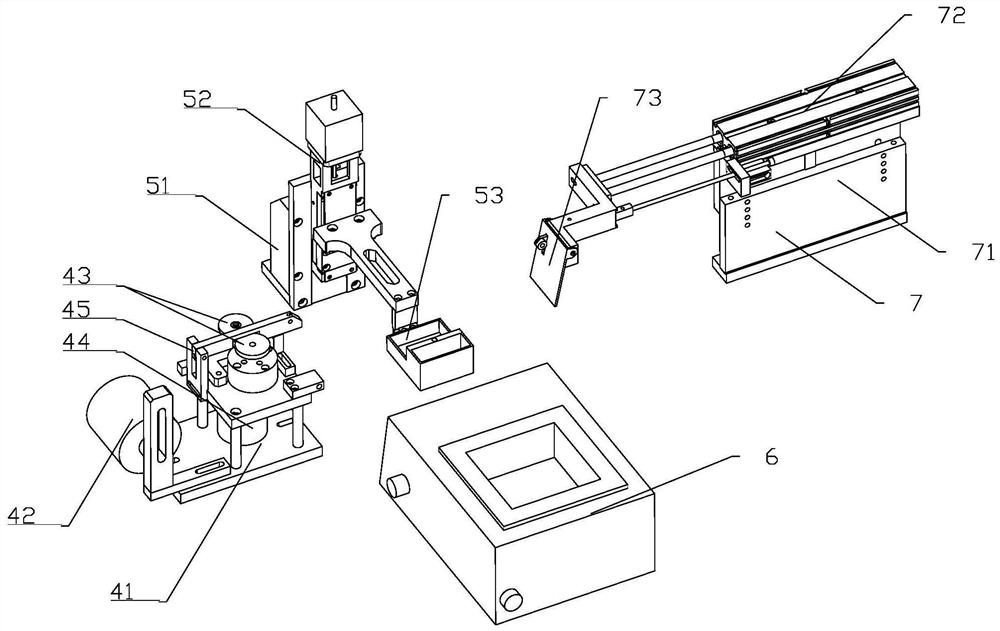

[0023] Such as figure 1 As shown, a tin coating device at the end of a coaxial cable includes a frame 1 and a feeding assembly 2 installed on the frame 1, a turning mechanism 3, a tin feeding wire assembly 4, a tin pool assembly 5, a heating box 6, The tin scraping assembly 7 and the jig; the turning mechanism 3 is connected with the feeding assembly 2, and the jig provided with the coaxial cable is arranged on the upper end of the feeding assembly 2 and the turning mechanism 3; the heating box 6 is arranged on the frame and is located at the turning On the side of the mechanism 3 , the tin pool assembly 5 is located above the heating box 6 , and the tin scraping assembly 7 corresponds to the tin pool assembly 5 and is located on the side of the tin pool assembly 5 .

[0024] The material passing assembly 2 is used to pass the jig equipped with the coaxial cable, the turning mechanism 3 is used to clamp the jig, and rotate the jig to apply tin; the heating box 6 is used to tin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com