Method and special device for growing large-size titanium alloy crystals through laser-assisted heating

A laser-assisted, titanium alloy technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of uneven heating, incomplete melting of the core, unstable floating melting area, etc., to achieve uniform heating, The effect of improving the solid-liquid interface, improving the seeding success rate and crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

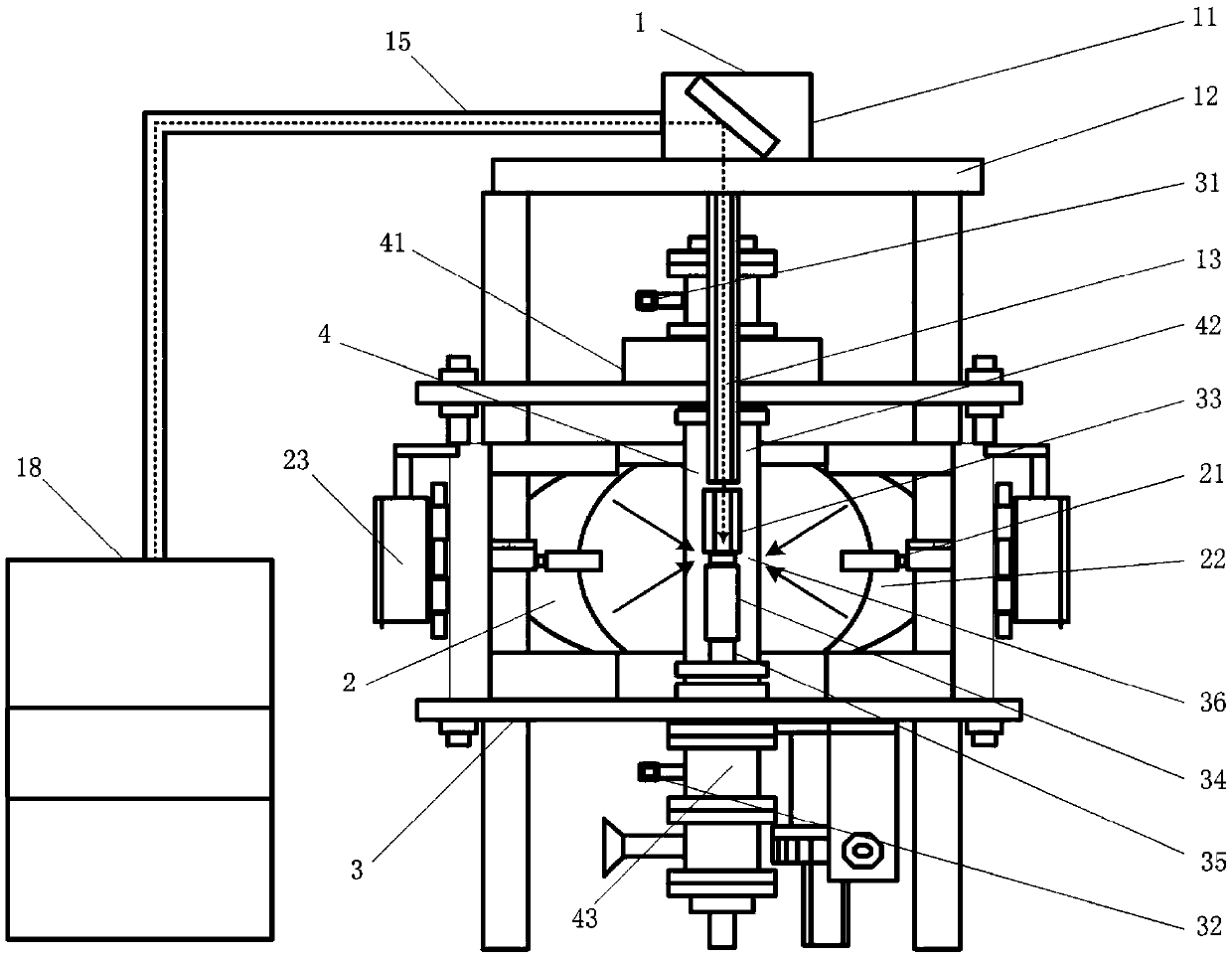

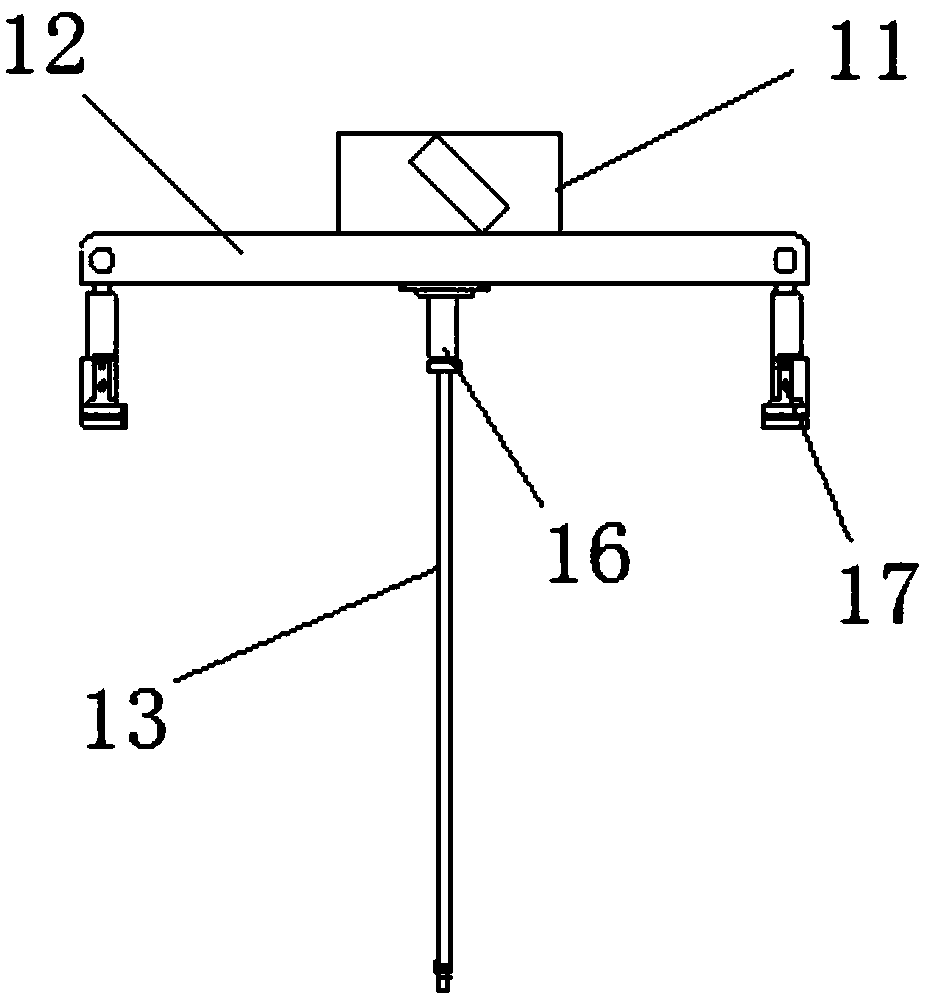

[0050] Preparation of oriented TiNb crystals with a diameter of 30 mm:

[0051] Growth speed: 6mm / h, rotation speed of feeding rod 33: 10r / min, xenon lamp power 1.5kw (external heating), laser power 0.2kw (core heating), laser heating is introduced after the xenon lamp is turned on for 5 minutes, and laser heating The power is evenly adjusted from 0W to 0.2kw at a speed of 6W / min to realize the coordinated heating of the xenon lamp and the laser, and finally prepare a large-sized TiNb crystal with a diameter of 30mm.

Embodiment 2

[0053] Preparation of oriented TiAl crystals with a diameter of 33 mm:

[0054] Growth speed: 5mm / h, rotation speed of feeding rod 33: 9r / min, xenon lamp power 2.0kw (external heating), laser power 0.2kw (core heating), laser heating is introduced after the xenon lamp is turned on for 5 minutes, and laser heating The power was uniformly adjusted from 0W to 0.2kw at a speed of 6W / min to realize the coordinated heating of the xenon lamp and the laser, and finally a large-sized TiAl crystal with a diameter of 33mm was prepared.

Embodiment 3

[0056] Preparation of oriented TiAlNb crystals with a diameter of 30 mm:

[0057] Growth speed: 15mm / h, rotation speed of feeding rod 33: 12r / min, xenon lamp power 6.0kw (external heating), laser power 0.6kw (core heating), laser heating is introduced after the xenon lamp is turned on for 6 minutes, and laser heating The power was evenly adjusted from 0W to 0.6kw at a speed of 8W / min to realize the coordinated heating of the xenon lamp and the laser, and finally a large-sized TiAlNb crystal with a diameter of 30mm was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com