Preheating type combustion coil condensation heat exchanger

A technology of condensing heat exchanger and combustion plate, applied in burners, gas fuel burners, combustion methods, etc., can solve the problems of inability to meet the requirements of energy saving and environmental protection, different understanding of technology, immature technology, etc., and achieve convenient after-sales service. The effect of maintenance, avoidance of water-vapor tightness leakage, and avoidance of welding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

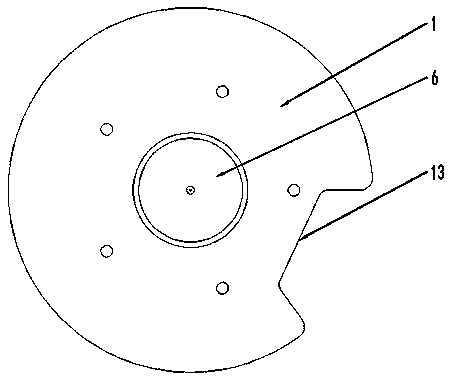

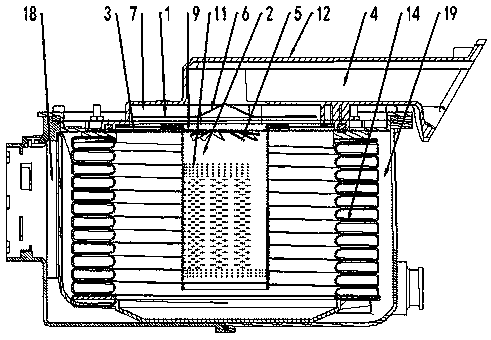

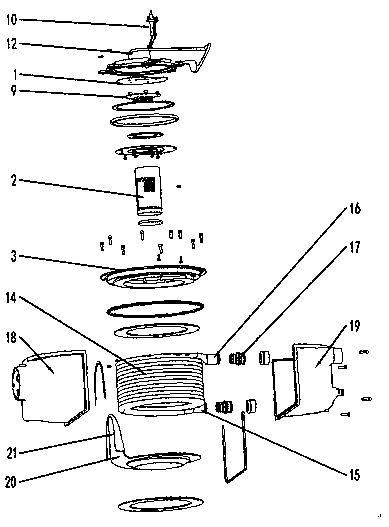

[0037] Examples such as Figure 1-9 As shown, a preheating combustion coil condensing heat exchanger includes a detachable main body, and the detachable main body is sequentially provided with a pretreatment device for preheating and mixing the gas to be combusted by using the waste heat of the equipment itself according to the flow direction of the gas, A burner 2 for gas combustion and a heat collector for energy absorption by the medium (water).

[0038] The detachable body includes an upper cover 12 arranged above the burner 2 , and the pretreatment device is located between the burner 2 and the upper cover 12 .

[0039] The upper cover 12 is provided with an air intake cavity 4 for easy gas entry, the lower end of the upper cover 12 is encapsulated by a ring-shaped sealed upper cover 3 , and the burner 2 is mounted on the sealed upper cover 3 .

[0040] The heat collecting device is arranged under the sealed upper cover 3, and the heat collecting device is a coil 14, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com