Gluing information detection method based on structured light measurement

An information detection and structured light technology, which is applied in measurement devices, optical devices, image data processing, etc., can solve problems such as inability to effectively detect glue strip information, affecting the accuracy of glue coating information detection, and limitations, and achieve solutions. Black glue detection or contrast is not obvious, glue strip detection, high accuracy, the effect of solving technical difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

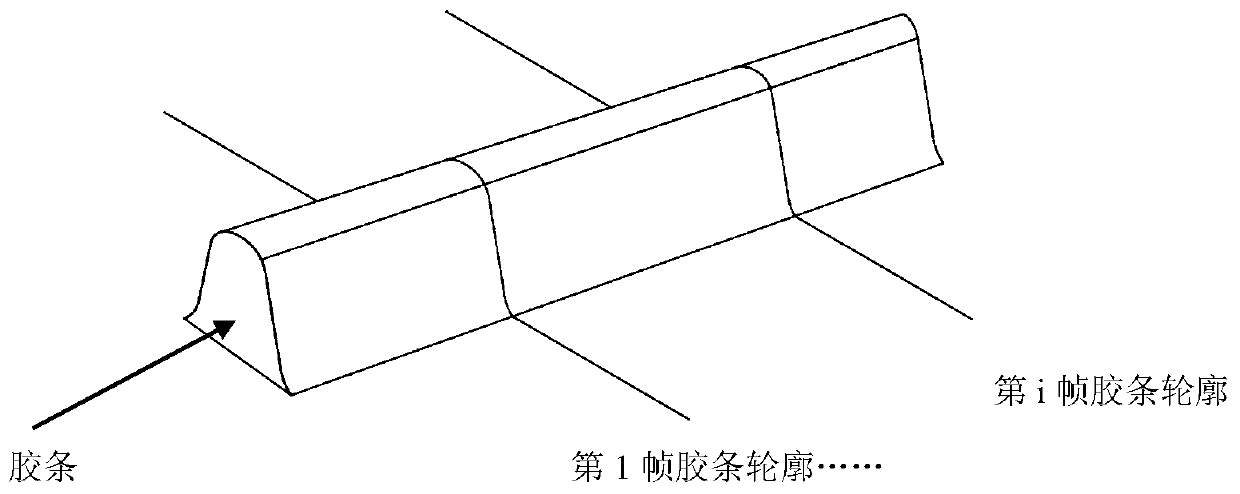

[0031] In this example, the glue applied to the windshield of the car is taken as an example, and the information of the glue strip is detected by using structured light. The glue strip is black triangular glue, and the sampling rate of the linear structured light sensor is 1500 frames / s; The moving speed of the glue strip is 100mm / s, as follows:

[0032] A method for detecting glue coating information based on structured light measurement, comprising the following steps:

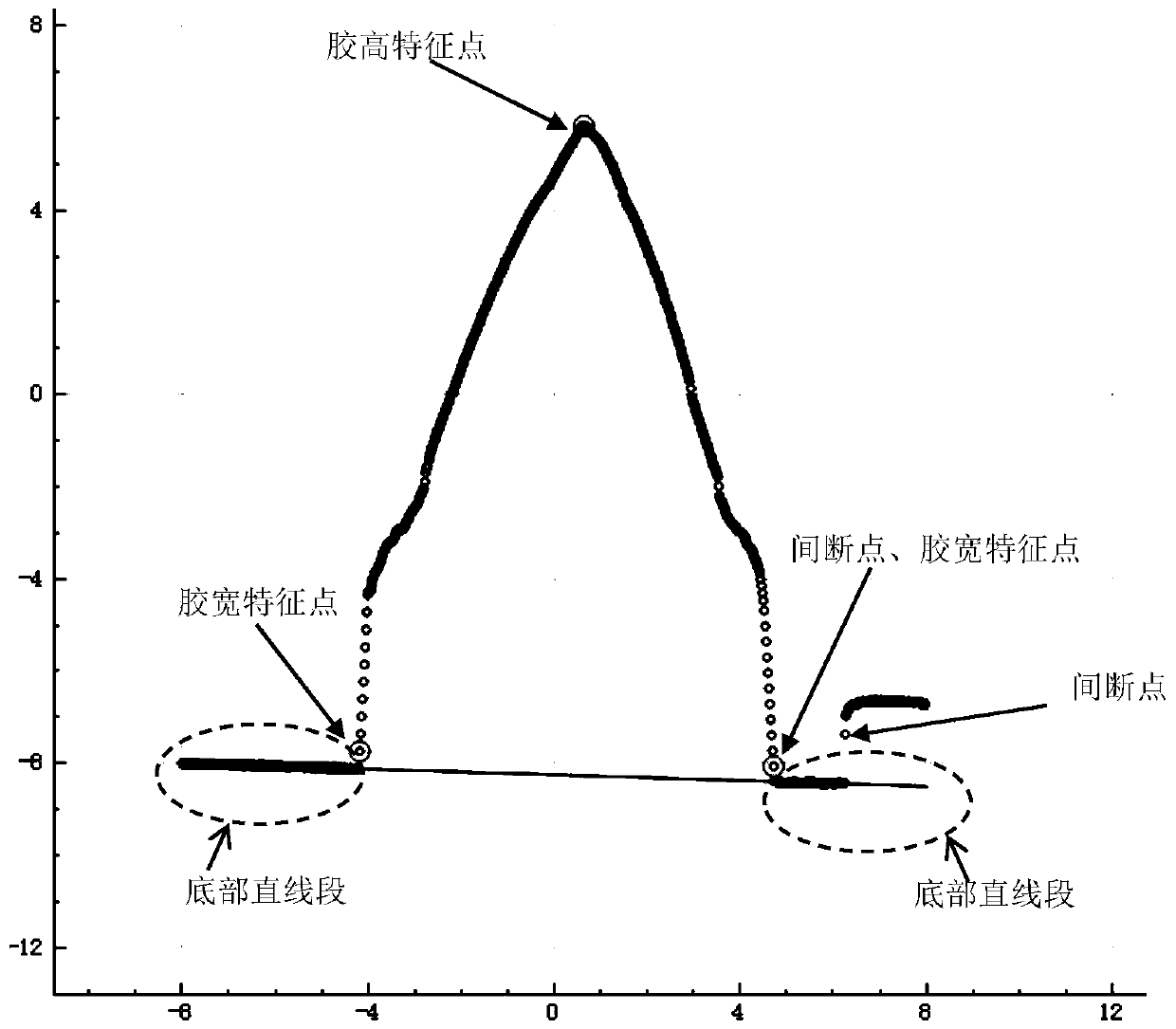

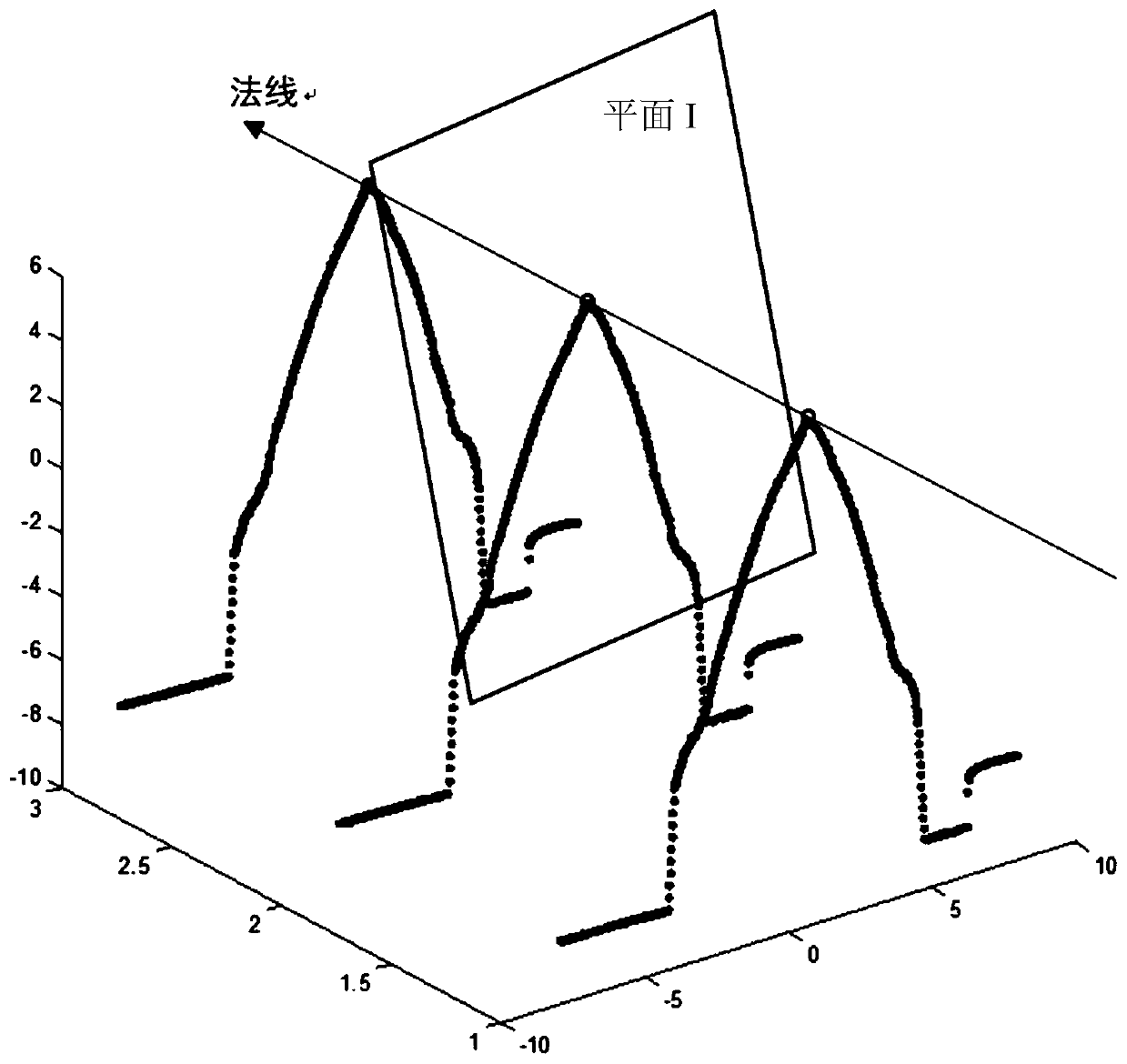

[0033] 1) The line structured light sensor obtains the structured light image of the strip outline in real time, performs image processing on the structured light image of the strip outline, segmentes the bottom straight line segment in the strip outline, and fits the bottom straight line segment to obtain the bottom reference line ;

[0034] 2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com