Fire-fighting simulation training system for hazardous chemical substance tank car

A technology for simulation training and hazardous chemicals, which is applied in the field of firefighting training, can solve the problems of inability to truly simulate the explosion and leakage combustion of hazardous chemicals tank trucks, so as to reduce the rupture recovery time, strengthen the rupture effect, and improve the rupture speed and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and implementation examples.

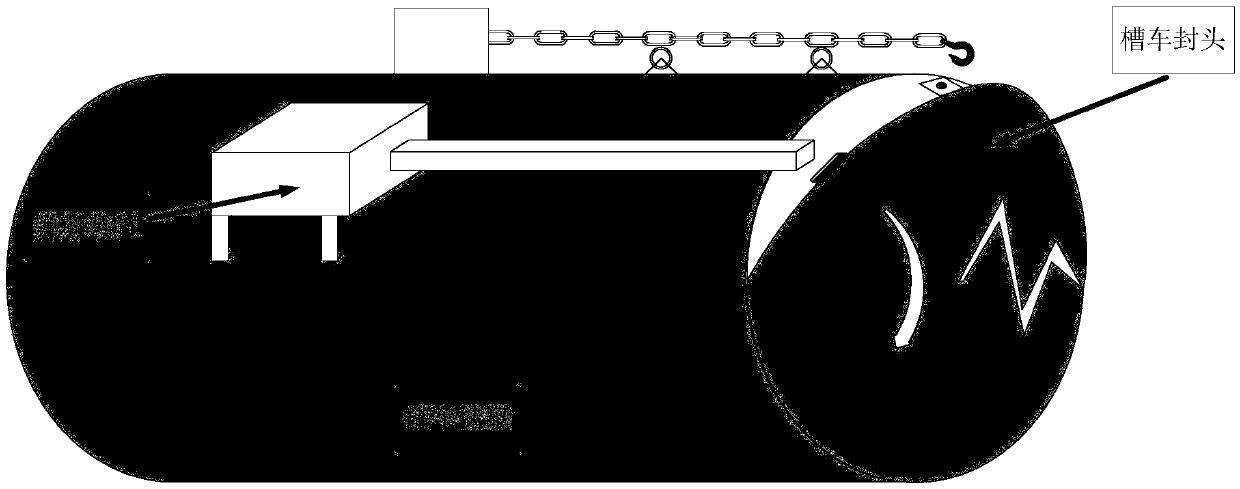

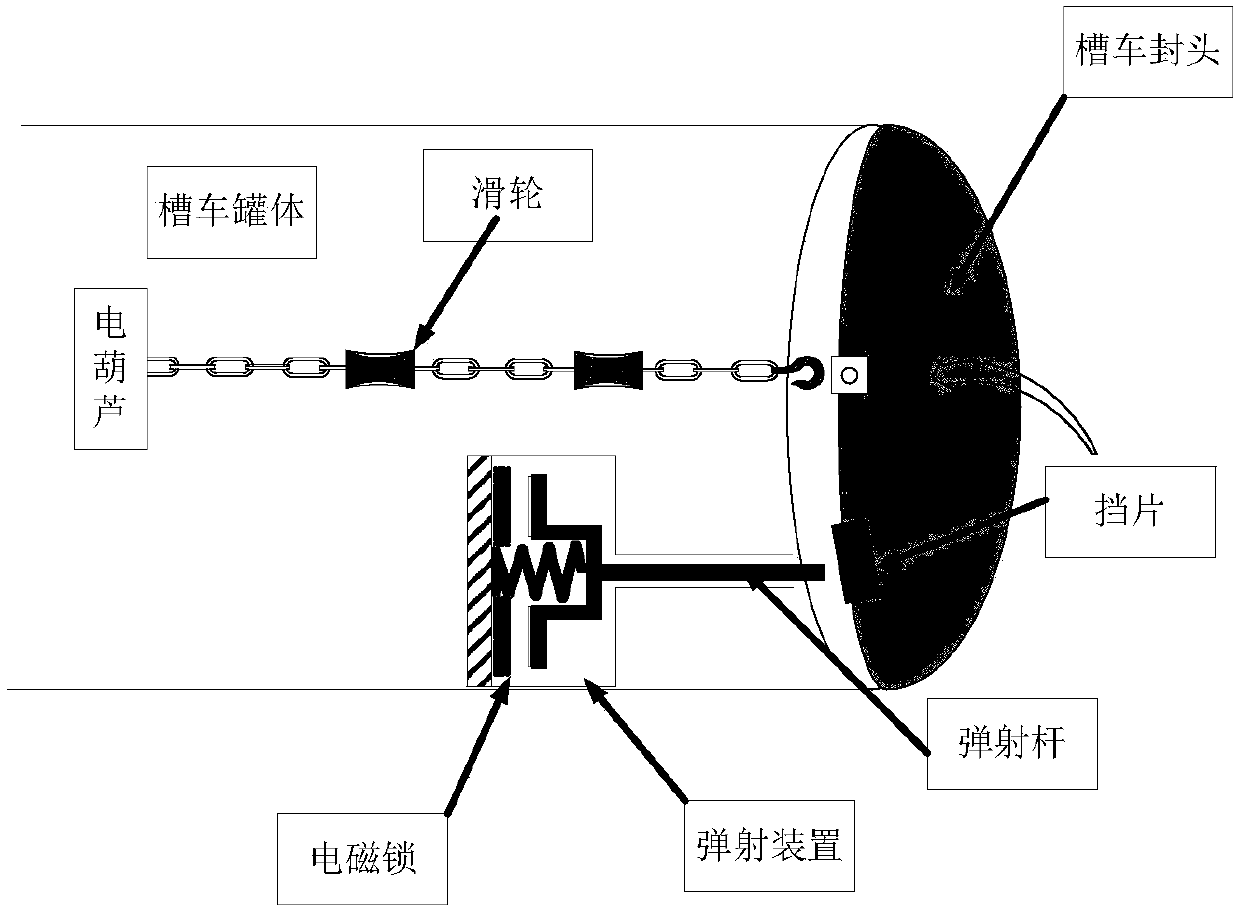

[0032] Such as figure 1 As shown, the hazardous chemical tanker head rupture system of the present invention is generally designed with two execution systems, namely the electromagnetic lock ejection rupture system and the electric hoist recovery system. The electromagnetic lock ejection rupture system is installed on the side of the tank truck for hazardous chemicals, and the bracket is used to fix the ejection rod and align it with the baffle on the rupture head of the tank truck. The electric hoist recovery system is installed on the top, with two fixed pulleys to guide the movement of the chain.

[0033] figure 2 The electromagnetic lock ejection rupture system shown includes a "bow"-shaped ejection rod, a high-pressure spring, and two electromagnetic locks. One end of the electromagnetic lock is fixed on the bottom plate of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com