Method for depositing aluminum nitride film on silicon substrate and silicon wafer

A technology of aluminum nitride film and silicon substrate, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve problems such as single method and cannot meet production needs, and achieve the effects of reducing costs, shortening production cycles, and enriching the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

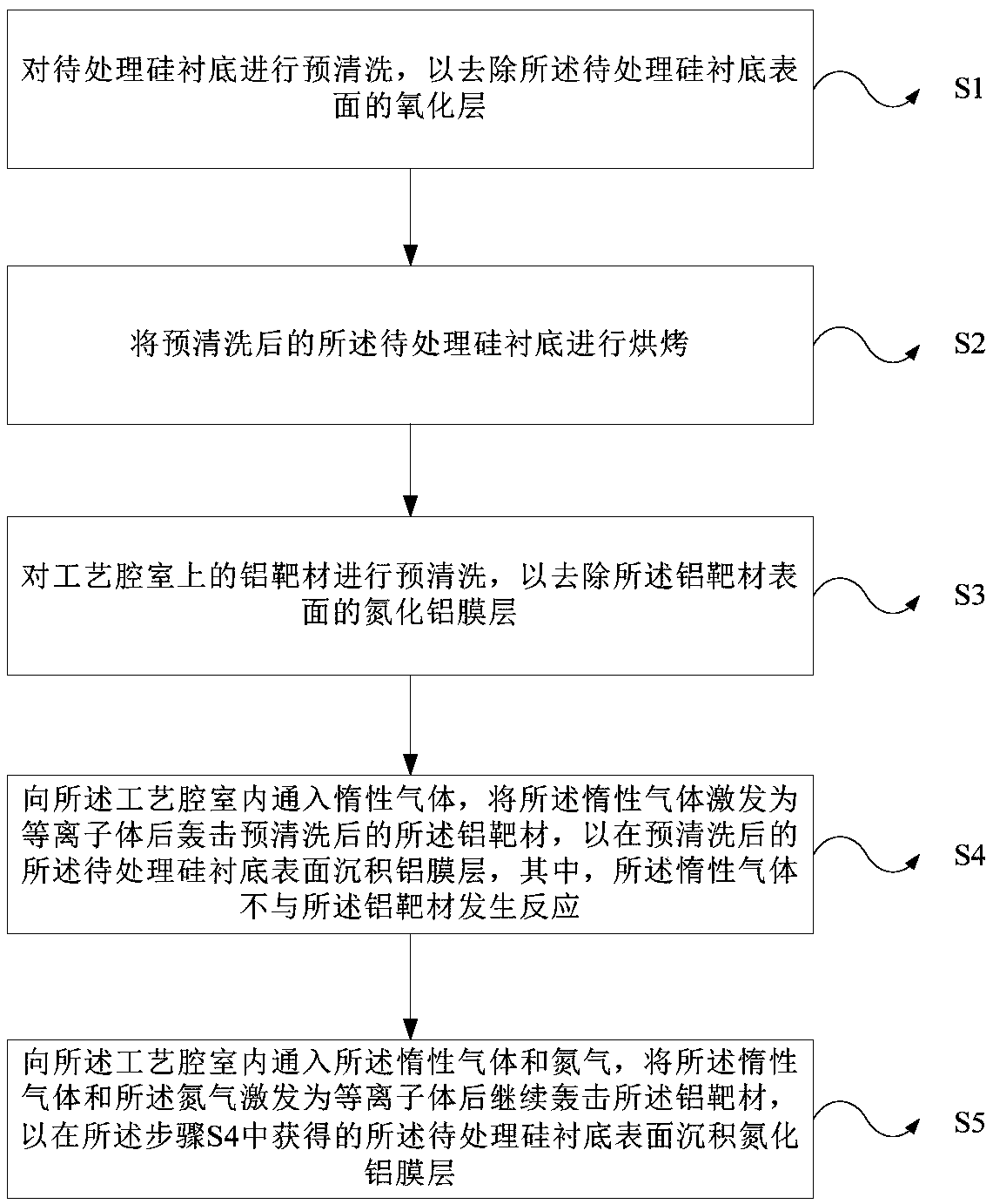

[0026] As one aspect of the present invention, a method for depositing an aluminum nitride film on a silicon substrate is provided, wherein, as figure 1 shown, including the following steps:

[0027] Step S1, pre-cleaning the silicon substrate to be processed, so as to remove the oxide layer on the surface of the silicon substrate to be processed;

[0028] Step S2, baking the pre-cleaned silicon substrate to be processed;

[0029] Step S3, pre-cleaning the aluminum target on the process chamber to remove the aluminum nitride film on the surface of the aluminum target;

[0030] Step S4, injecting an inert gas into the process chamber, exciting the inert gas in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com