Automatic drill bit grinding equipment

An automatic and drill technology, applied in drilling/drilling equipment, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of large processing error, low processing accuracy, low production efficiency, etc. Consistent material, improve work efficiency and save time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

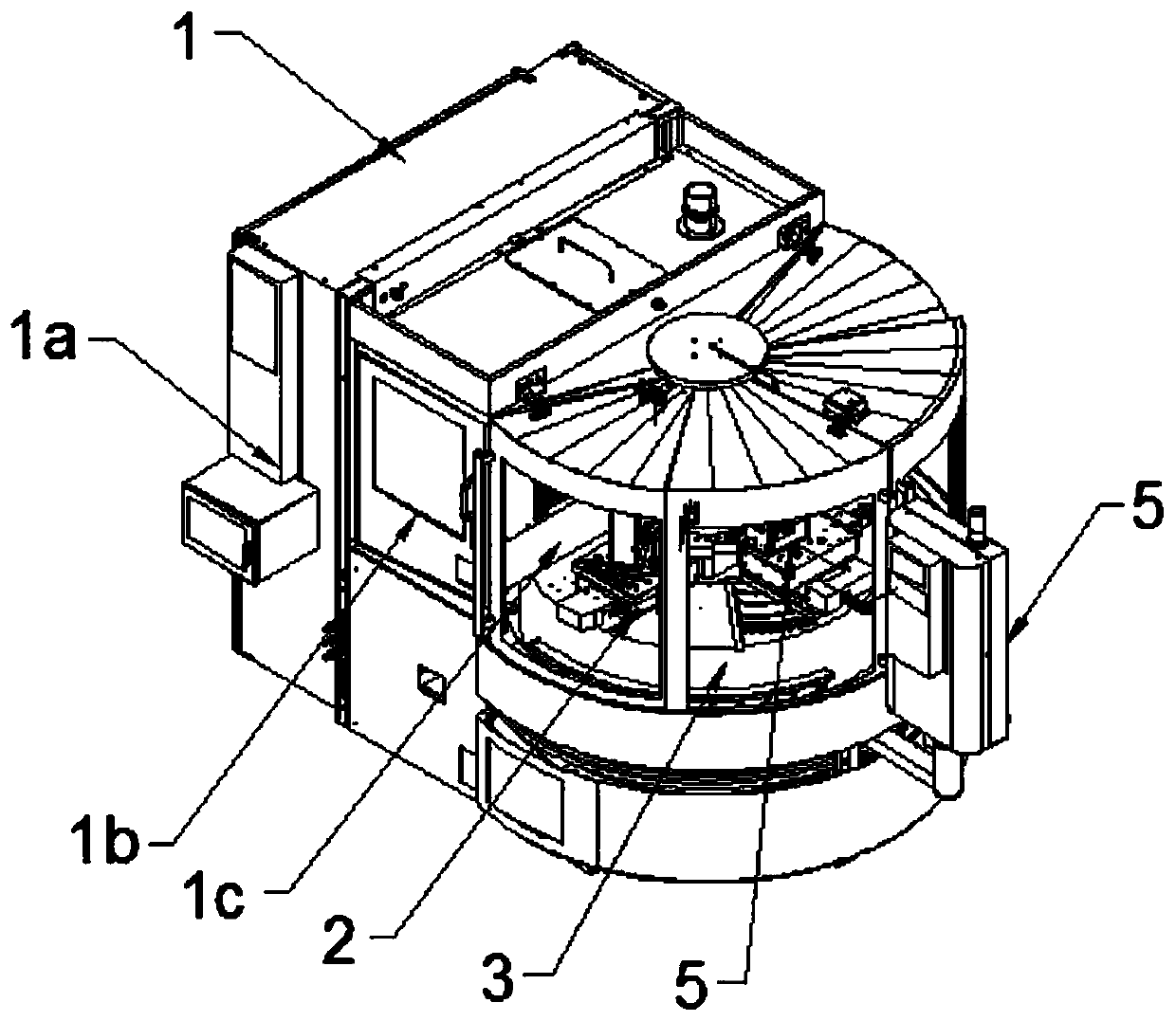

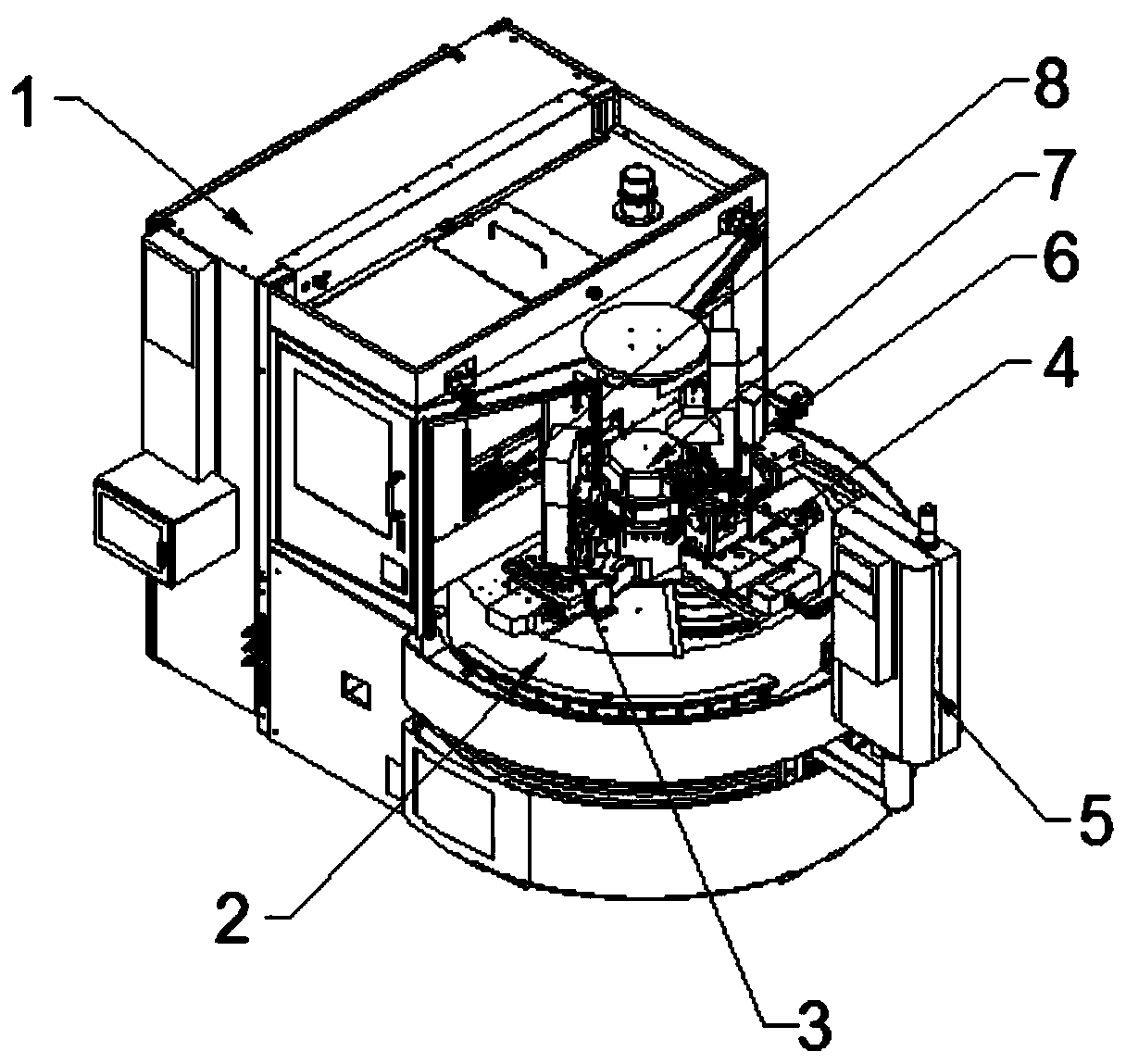

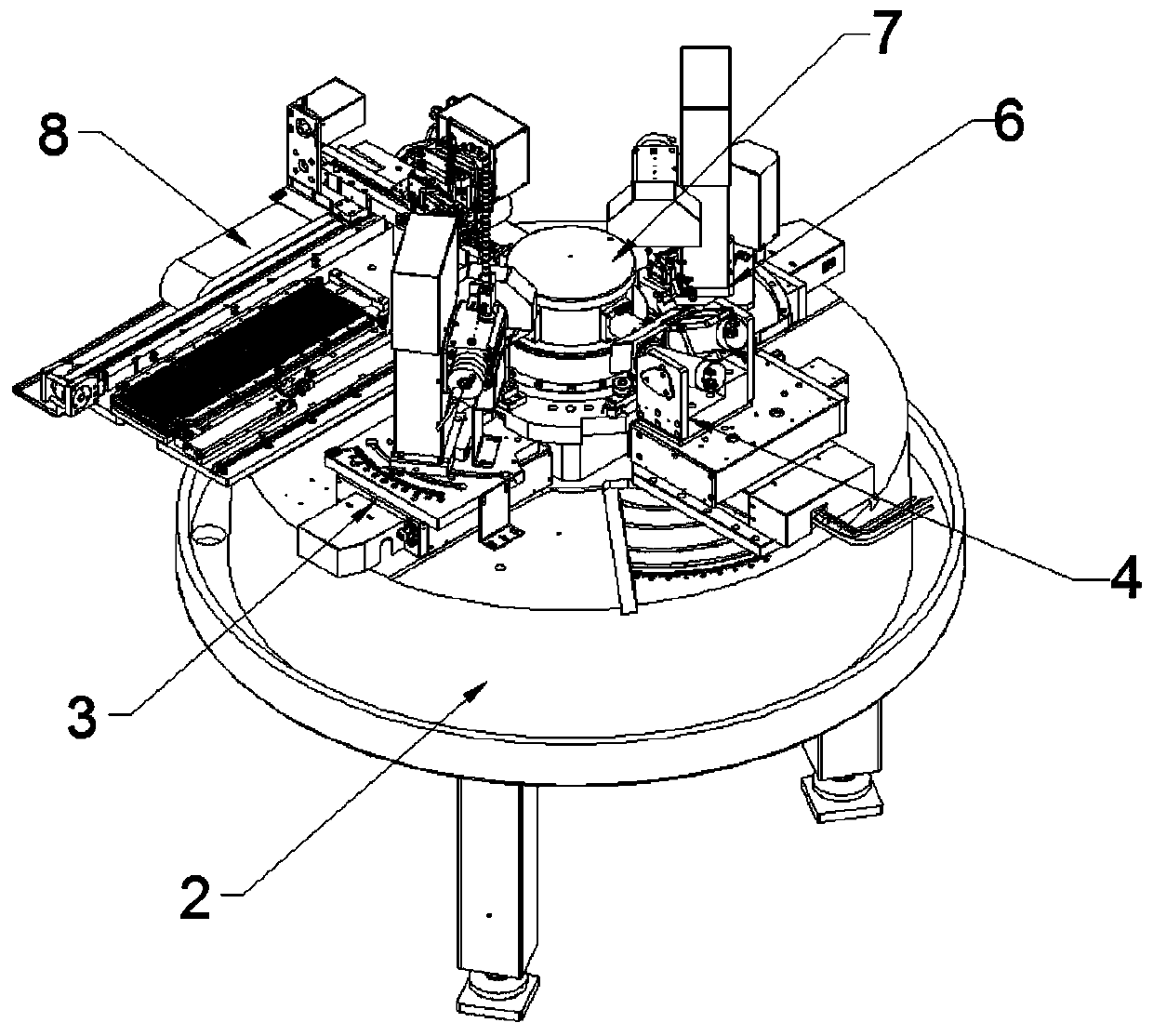

[0047] see Figure 1-5 , the present embodiment provides an automatic drill bit grinding device, including a machine 2, on which a slotting station module 3, a sharpening station module 4, a grinding station module 6, a rotary multi- Station processing module 7, loading and unloading module 8, slotting station adjustment seat 9, supporting tool holder 10, index sensor 11, sharpening station adjustment seat 12 and grinding back station adjustment seat 13, rotary multi-station processing mold The group 7 is located at the upper middle part of the machine platform 2, and several working heads 14 are arranged on the rotary multi-station processing module 7. In this embodiment, the number of working heads 14 is set to four, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com