Process method for reducing the center segregation of billet

A process method and casting slab technology, applied in the direction of manufacturing converters, etc., can solve the problem of not being able to meet the quality requirements of high-quality, high value-added steel grades, the effect of center segregation control and mitigation is limited, and the centerline segregation of the casting slab can only be reduced but not completely Eliminate other problems, achieve the effect of reducing molten steel inclusions, improving the purity of molten steel, and compacting the central solidified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

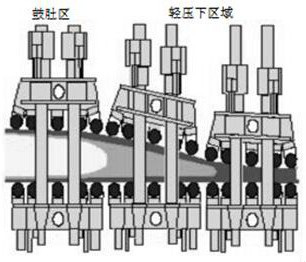

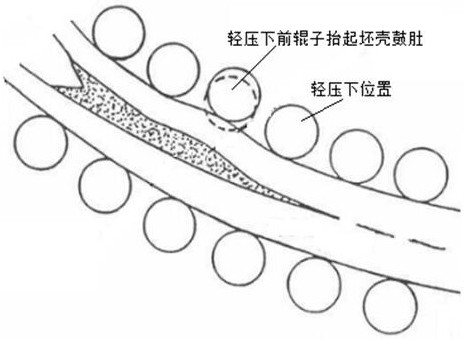

[0022] Embodiment 1: see figure 1 , figure 2 , a process method for reducing slab center segregation, said method comprising the following steps:

[0023] 1) Purity of molten steel and control of inclusions in steel;

[0024] According to the cavity suction theory in the core of the slab: at the end of the solidification of the slab, the liquid phase changes into a solid phase, the volume shrinks, and a certain cavity is generated in the central area of the slab; the bulging of the slab causes the cavity in the core With negative pressure, the molten steel enriched with solute elements between dendrites is sucked into the core, resulting in central segregation. In addition, due to the different solubility of solute elements in liquid and solid state, segregation occurs during the solidification process. Segregation is an inevitable phenomenon in the solidification process, but the degree of segregation can be controlled by improving equipment and processes.

[0025] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com