Discharge additive, printing paste and discharge printing method of polyester fabric

A polyester fabric, discharge dyeing printing technology, applied in the field of textile printing and dyeing, can solve the problems affecting the quality of fabrics, color shades, etc., to achieve the effect of easy printing, clear patterns, and simplified discharge printing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

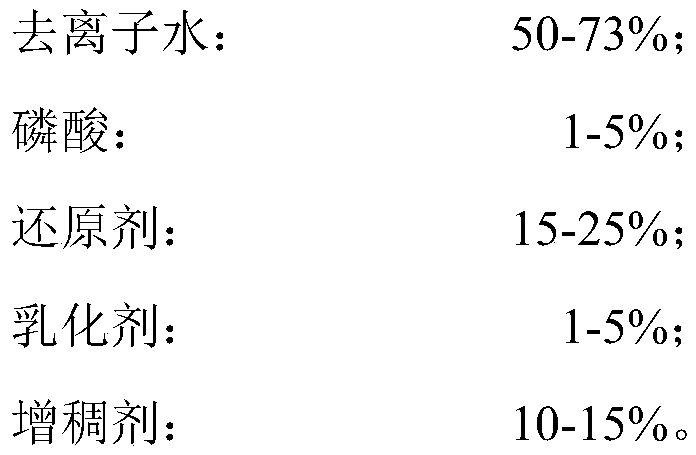

[0037] The discharge aid for polyester fabric of this embodiment includes the following components by weight percentage:

[0038] Component Weight percentage Deionized water50% Phosphoric acid5% Stannous chloride dihydrate25% Naphtha5% Guar Gum15%

[0039] The printing paste of the polyester fabric of this embodiment includes the following components by weight percentage:

[0040] Component Weight percentage Dye discharge aid of this embodiment 97%; P-type disperse dyes 3%;

Embodiment 2

[0042] This embodiment provides a discharge printing method for polyester fabric (polyester fabric is polyester / spandex weft knitted fabric), which includes the following steps:

[0043] (1) Dyeing of polyester fabric

[0044] Using heterocyclic azo disperse dyes, high-temperature dyeing of polyester fabrics, dyeing temperature 130 ℃, dyeing time 30 minutes.

[0045] (2) According to the formula of Example 1, the components are weighed and mixed to prepare a discharge aid. The viscosity of the discharge aid is 20,000 cps and the pH is 1-3.

[0046] (3) According to the formula of Example 1, a printing paste is obtained.

[0047] (4) Printing: matching printing screen made of 1350# and 800# mesh, 65H hardness scraper, flat screen printing after scraping, so that the printing paste forms a colored pattern on the surface of the polyester fabric .

[0048] (5) Steaming: Use a high-temperature continuous steaming machine to steam at 170 degrees Celsius for 8 minutes. Under high temperature ...

Embodiment 3

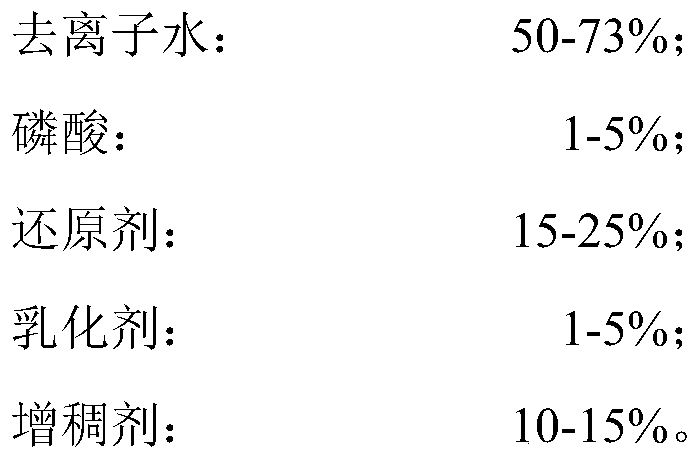

[0051] The discharge aid for polyester fabric of this embodiment includes the following components by weight percentage:

[0052] Component Weight percentage Deionized water73% Phosphoric acid1% Stannous chloride dihydrate15% Naphtha1% Guar Gum10%

[0053] The printing paste of the polyester fabric of this embodiment includes the following components by weight percentage:

[0054] Component Weight percentage Dye discharge aid of this embodiment 94%; P-type disperse dyes 6%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com