System capable of recovering flue gas waste heat for ultra-clean flue gas discharge and zero wastewater discharge of power plant

A flue gas waste heat and zero-emission technology, applied in the direction of reducing greenhouse gases, climate sustainability, lighting and heating equipment, etc., can solve the problems of evaporation energy consumption and high operating costs, and achieve high system reliability and environmental protection. The effect of high system reliability and flexible process selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

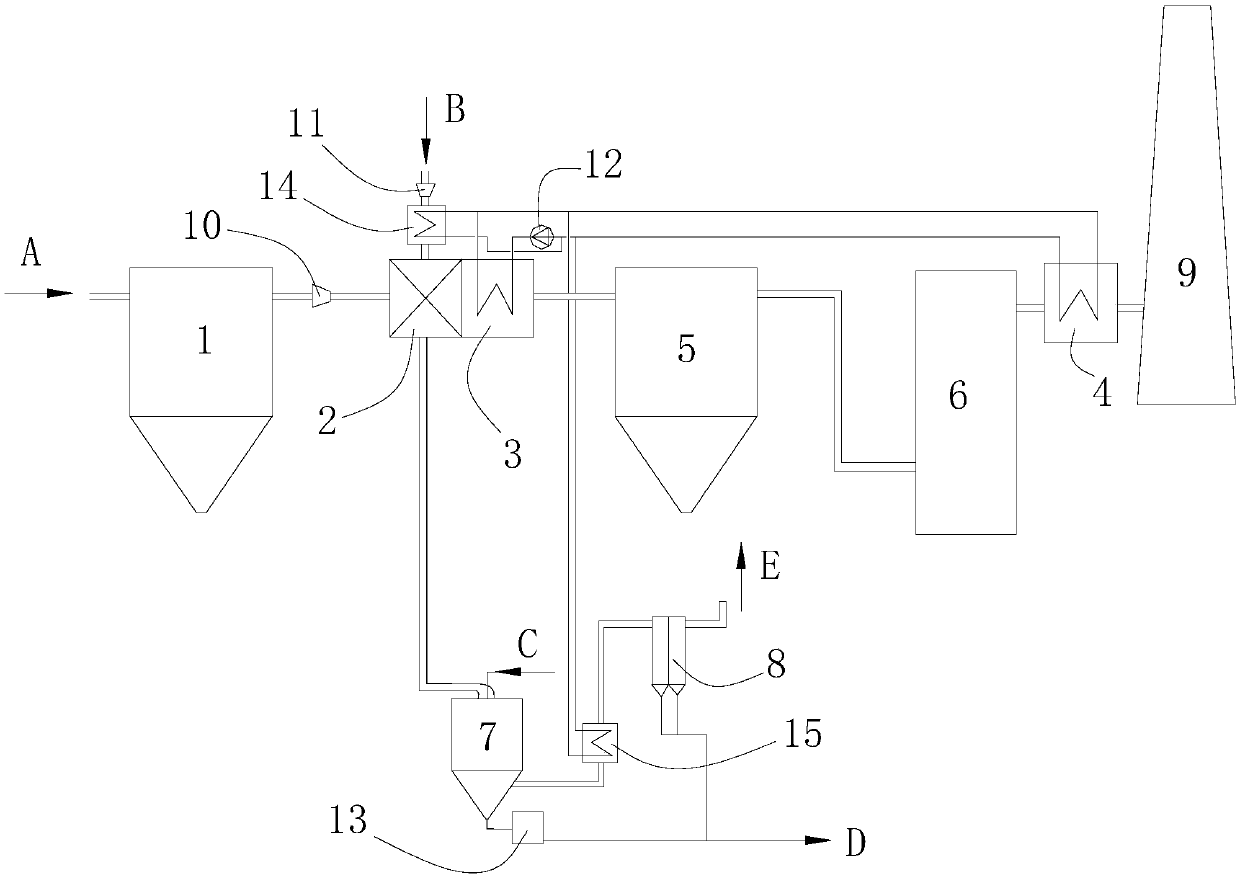

[0020] Some nouns involved in this embodiment are:

[0021] Air flue gas heat exchanger 2: air / flue gas heat exchanger, Air flue gas heat exchanger, referred to as AGH;

[0022] Intermediate heat medium flue gas / flue gas heat exchanger, also known as heat medium flue gas / flue gas heat exchanger, Intermediate heatmedium flue gas / flue gas heat exchanger, referred to as MGGH, in this application, intermediate heat medium flue gas / flue gas heat exchanger Including flue gas cooling heat exchanger 3 (MGGH1) and flue gas reheater 4 (MGGH2);

[0023] Intermediate heat medium air / flue gas heat exchanger, Intermediate heat medium air / flue gas heatexchanger, referred to as MAGH, in this application, intermediate heat medium flue gas / air heat exchanger includes heater 14 (MAGH1) and air reheater 15 (MAGH2).

[0024] refer to figure 1 , is a flue gas waste heat recovery system for ultra-clean discharge of flue gas and zero discharge of waste water in power plants, including dry electros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com