High-efficiency vibration-free gas-water heat exchanger

A water heat exchanger, high-efficiency technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc. Problems such as severe vibration of the heat pipe bundle can be eliminated to eliminate the risk of vibration, reduce the power consumption of the water pump, and increase the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

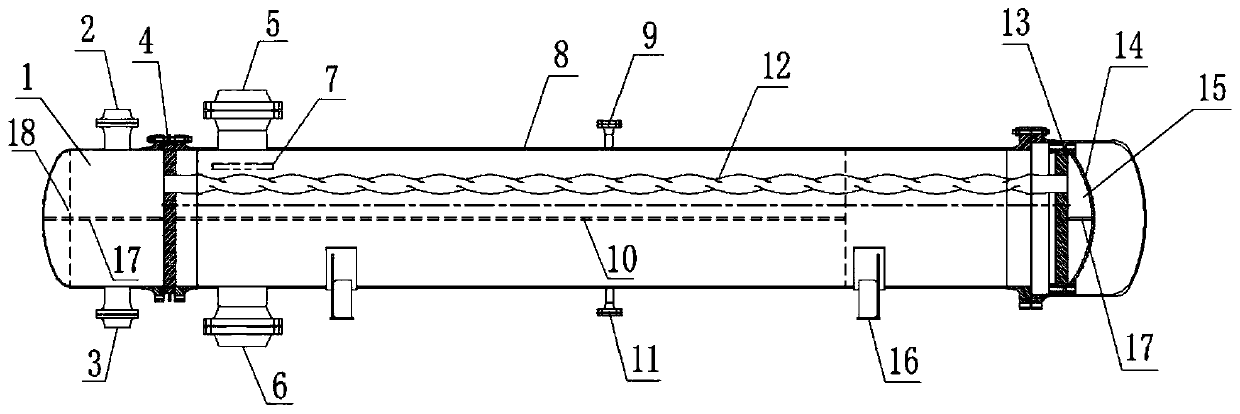

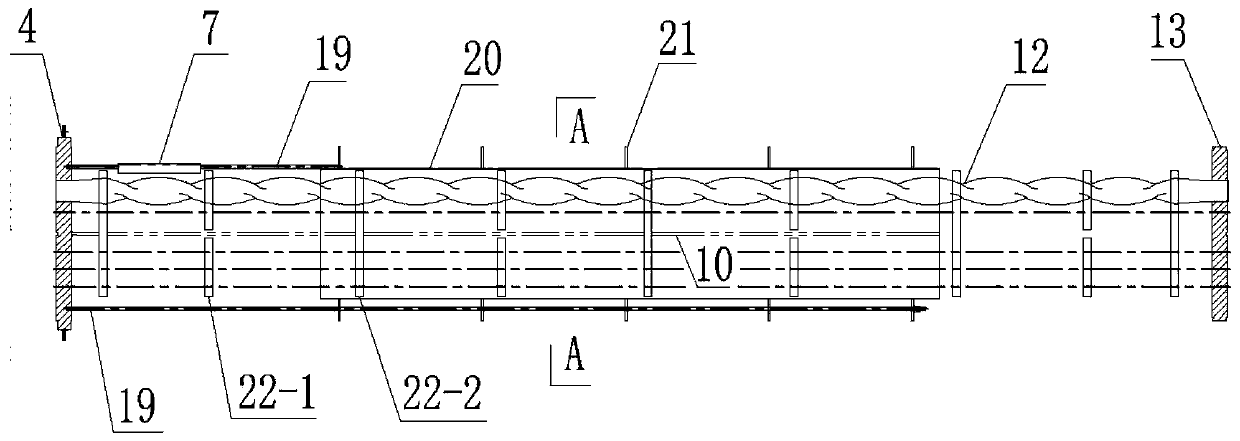

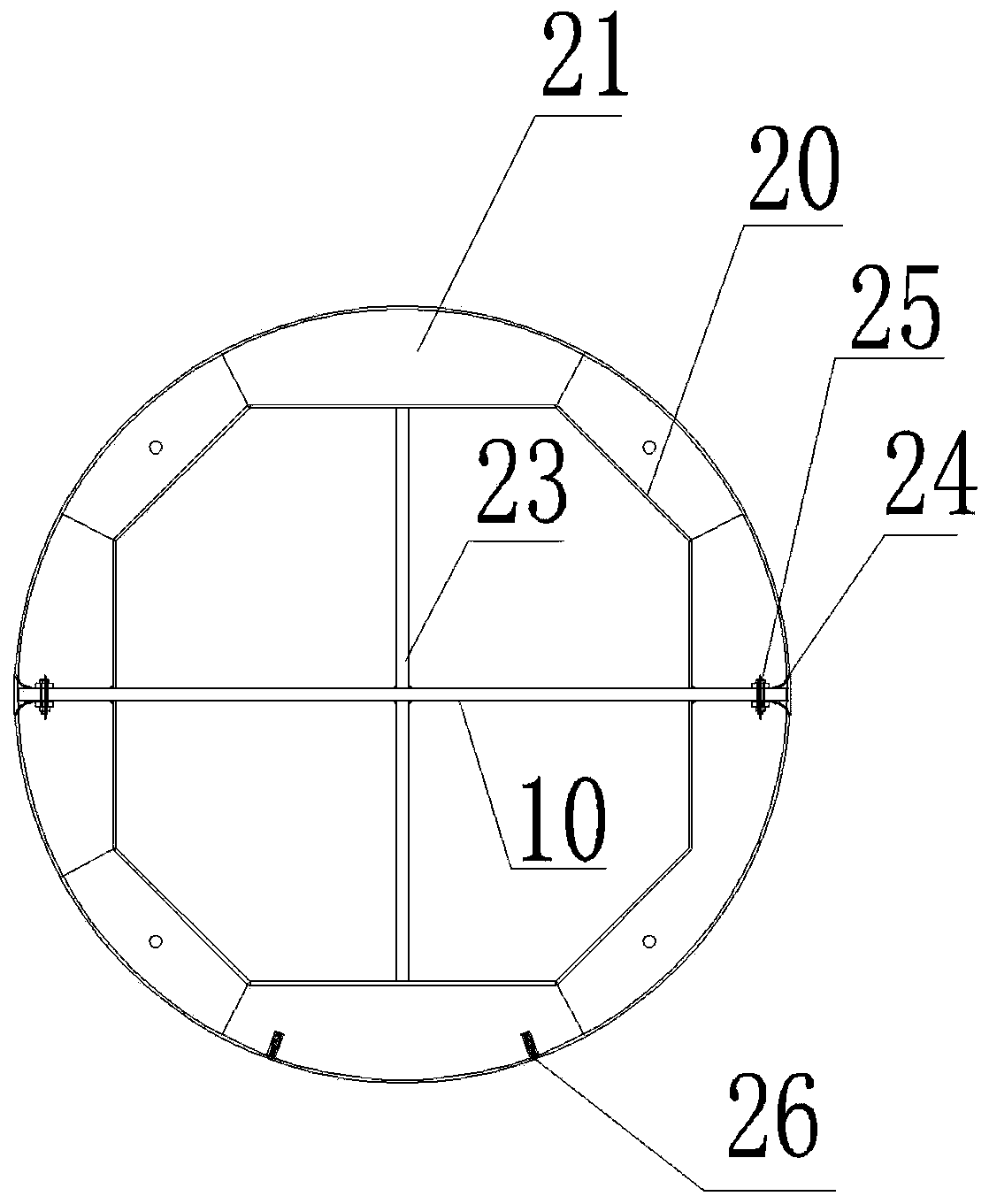

[0026] like figure 1 As shown, a high-efficiency and vibration-free air-water heat exchanger includes a cylinder body 8, the bottom of the cylinder body 8 is provided with a support 16, and the cylinder body 8 is provided with a cooling water inlet 3, a cooling water outlet 2, and a gas inlet 5 And the gas outlet 6, the cylinder 8 is equipped with a cooling core body, the cooling core body includes a heat exchange tube bundle 12 and a flow guide fastening cylinder 20, and the two ends of the cooling core body are provided with tube plates for fixing the position of the heat exchange tube bundle 12, Two tube sheets divide the inner space of cylinder 8 into three areas, the area between the two tube sheets is the heat exchange area, and the two areas outside the heat exchange area in the cylinder 8 are the first cooling water flow area 1 and the second cooling water flow area 15, the cooling water enters the shell 8 from the cooling water inlet 3 and flows out from the cooling w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap