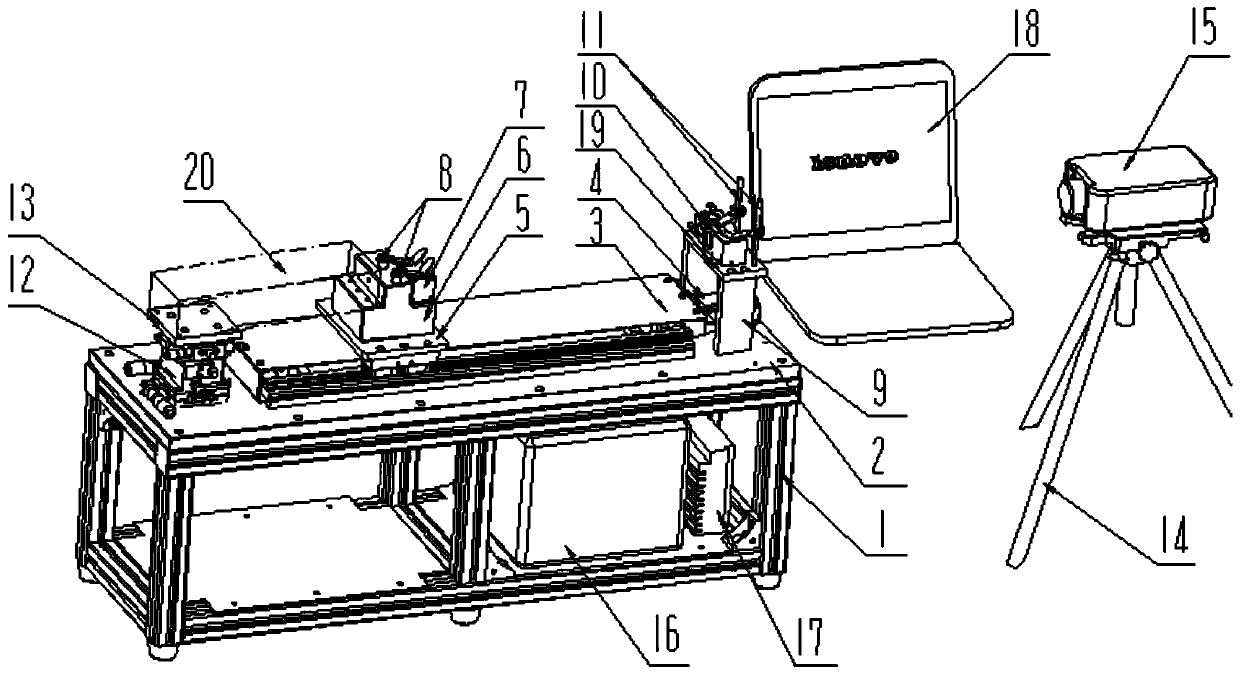

Comprehensive calibration device of linear displacement sensor

A technology of linear displacement sensor and displacement sensor, which is applied in the direction of measuring devices and instruments, can solve the problems of inconvenient operation, narrow applicability, and high cost, and achieve the effects of convenient installation, high work efficiency, and high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

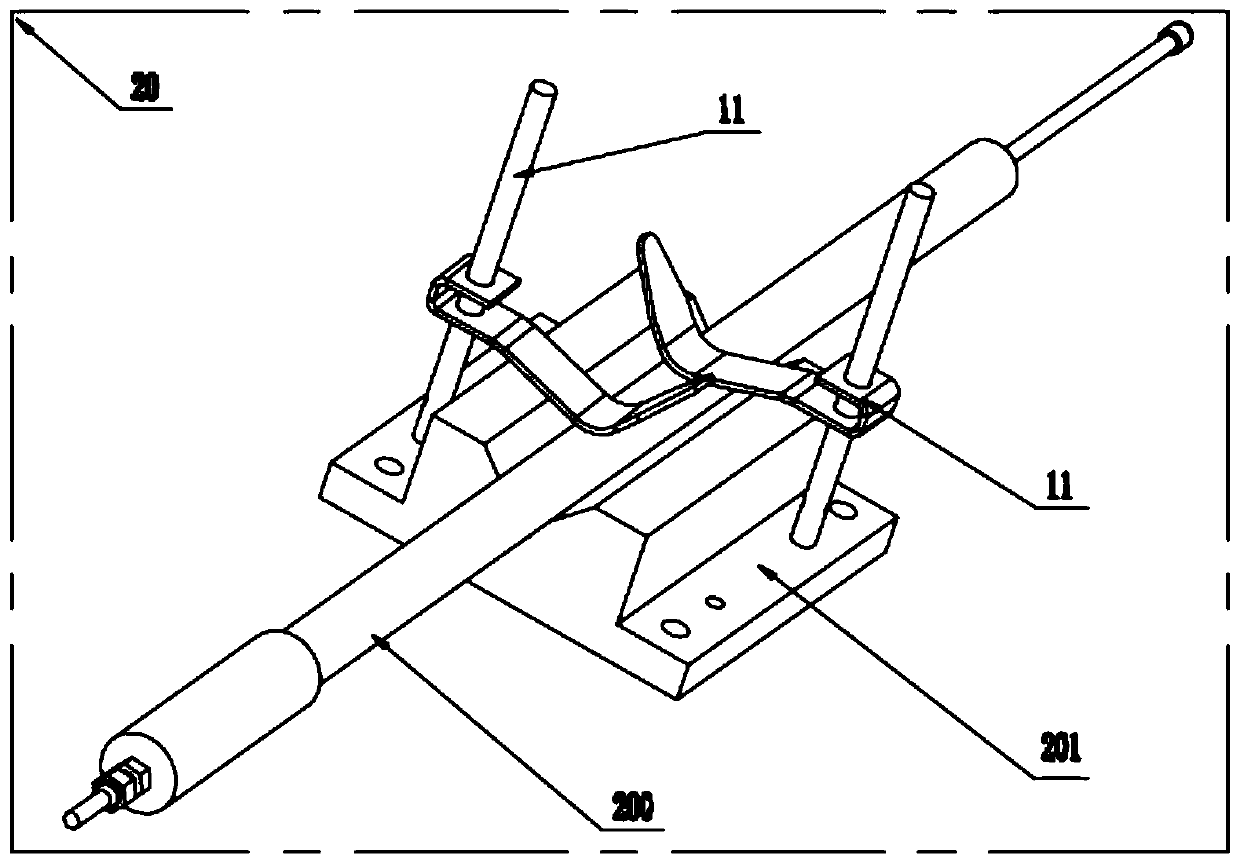

[0041] Embodiment 1: Utilizing a linear displacement sensor comprehensive calibration device of the present invention to calibrate a differential pressure transformer displacement sensor

[0042] The specific structure and connection relationship of the linear displacement sensor fixture 20 on the comprehensive calibration device of the linear displacement sensor of the differential pressure variable displacement sensor in the present invention: the connecting plate 13 is connected to the "V" shape of the differential pressure variable displacement sensor through the screw. The "V" groove mounting seat 201 is connected, and the elastic movable clamp 11 is also installed on the "V" groove mounting seat 201. The shell is clamped with elastic movable clamps 11. By adjusting the combined slide table 12, the measuring rod of the differential pressure transformer displacement sensor 200 is in contact with the end face of the positioning through hole of the slider base 6, so as to en...

Embodiment 2

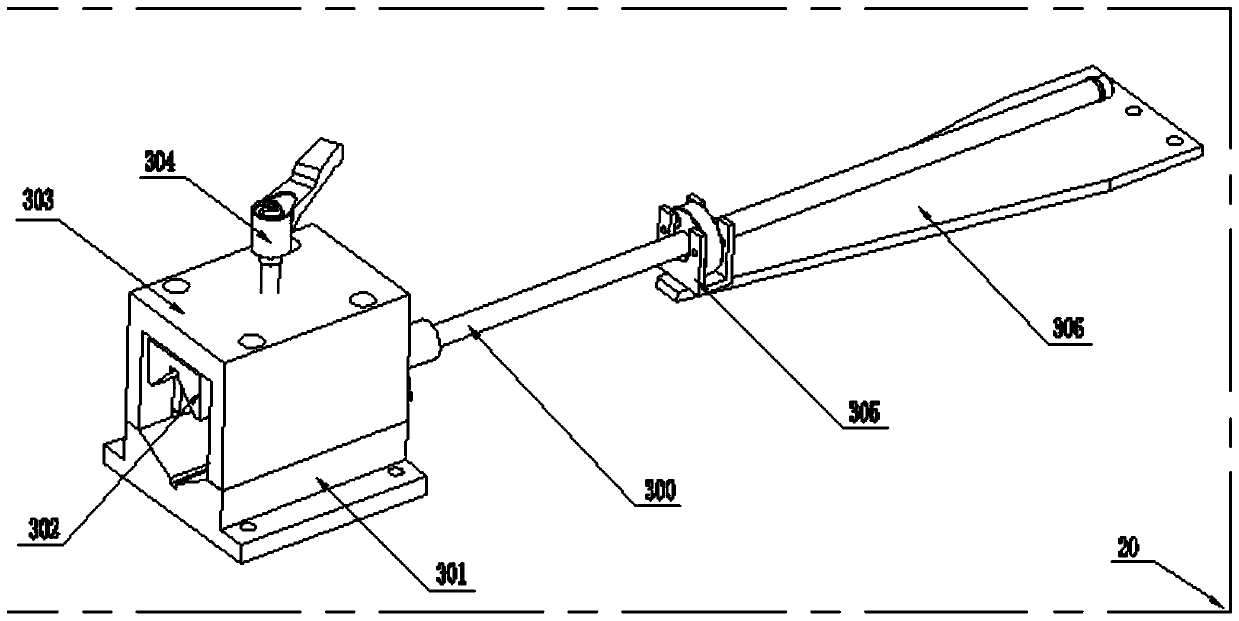

[0043] Embodiment 2: Utilize a linear displacement sensor comprehensive calibration device of the present invention to calibrate the magnetostrictive displacement sensor

[0044] The specific structure and connection relationship of the linear displacement sensor fixture 20 of the magnetostrictive displacement sensor on this comprehensive calibration device: the connecting plate 13 is installed with the lower V-shaped seat 301 by screws, and the fixed frame 303 is fixedly installed on the lower V-shaped seat 301, The upper V-shaped seat 302 is movable in the fixed frame 303, and the fast handle 304 that is spirally rotated in the fixed frame 303 can drive the upper and lower motions of the upper V-shaped seat 302 by the rotary motion of the fast handle 304. The magnetostrictive displacement sensor 300 The shell of the housing is placed between the lower V-shaped seat 301 and the upper V-shaped seat 302, thereby realizing the fast loading and unloading of the magnetostrictive di...

Embodiment 3

[0045] Embodiment 3: Utilizing a comprehensive calibration device for linear displacement sensors of the present invention to calibrate the pull-wire displacement sensor

[0046]The specific structure and connection relationship of the linear displacement sensor fixture 20 of the pull-wire displacement sensor on the comprehensive calibration device: the connecting plate 13 is installed with the flat-plate seat 401 of the pull-wire displacement sensor by screws, and elastic activities are installed on the flat-plate seat 401 of the pull-wire displacement sensor. Fixture 11, the pull-wire displacement sensor 400 to be calibrated is placed flat on the pull-wire displacement sensor flat seat 401 and positioned with positioning pins. After positioning, it is quickly clamped with elastic movable clamp 11; one end of 2# extension connecting plate 402 is fixed on the On the slider base 6, the other end of the 2# extended connecting plate 402 is equipped with a connecting shaft 403, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com