Improvement method for gas density relay

A gas density and relay technology, applied in the field of electric power, can solve the problems of reduced insulation strength on the surface of insulating parts, flashover, and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

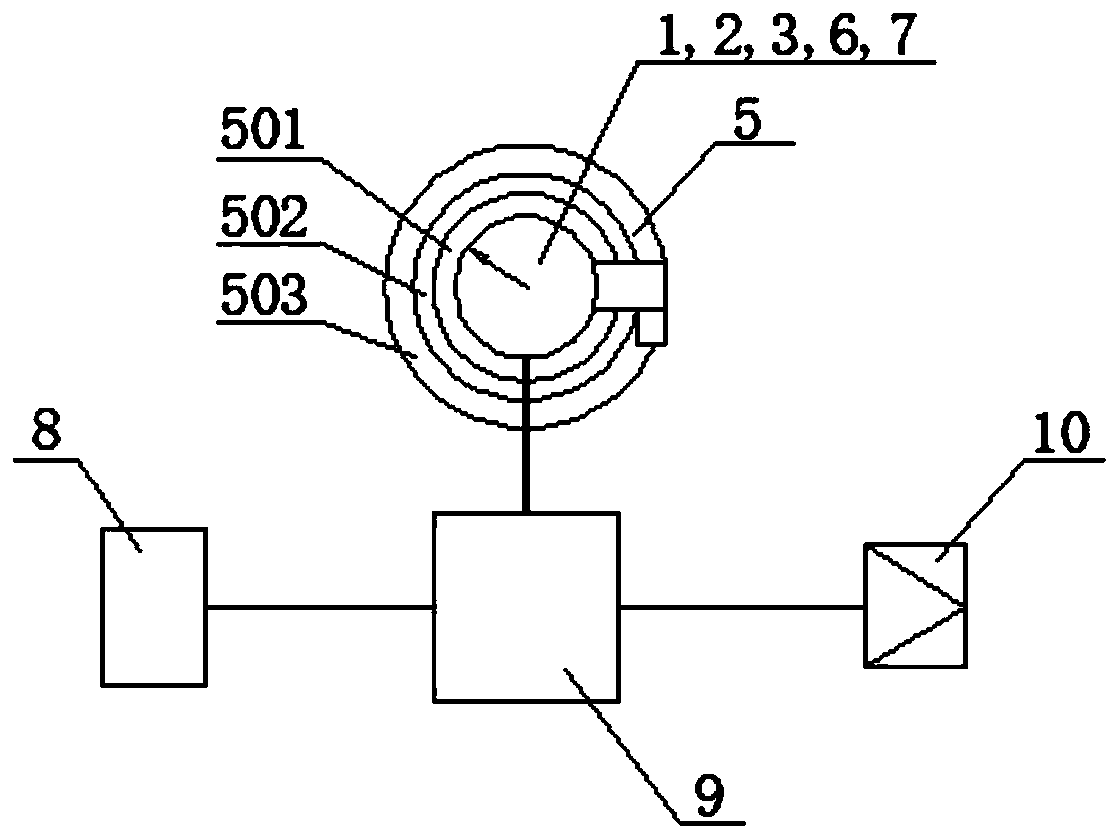

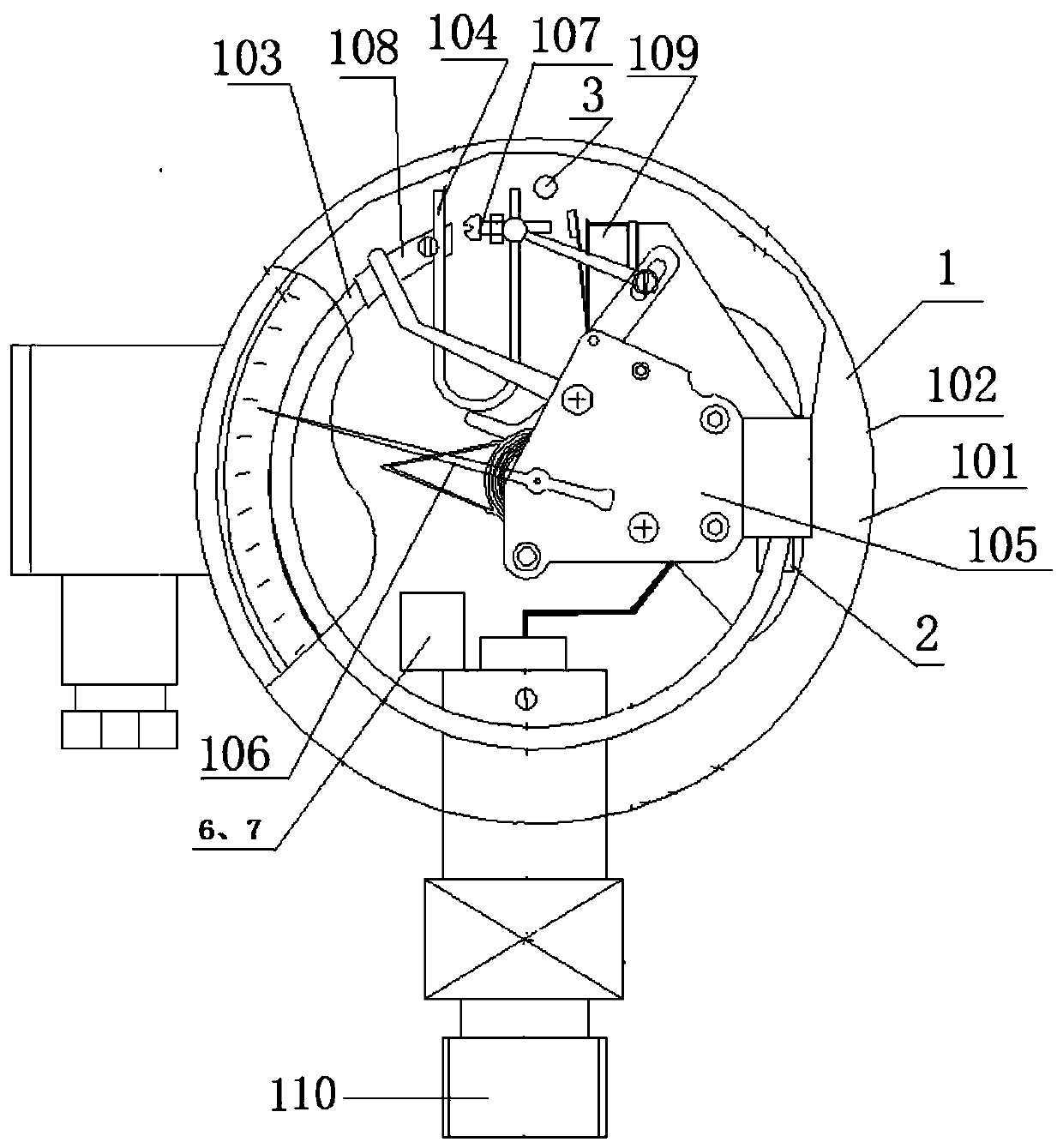

[0146] Such as figure 1 As shown, a gas density relay with an online self-verification function provided by Embodiment 1 of the present invention includes: a gas density relay body 1, a pressure sensor 2, a temperature sensor 3, a temperature adjustment mechanism 5, and an online verification contact signal sampling Unit 6, an intelligent control unit 7, a multi-way connector 9 and an air supply interface 10. The temperature adjustment mechanism 5 is arranged opposite to the gas density relay body 1 , and the temperature sensor 3 is arranged in the casing of the gas density relay body 1 . The gas density relay body 1 and the gas supply interface 10 are arranged on the multi-way joint 9 , and the pressure sensor 2 , the online verification contact signal sampling unit 6 and the intelligent control unit 7 are arranged on the density relay body 1 . The temperature adjustment mechanism 5 is arranged outside the density relay body 1 . Specifically, the gas density relay body 1 co...

Embodiment 2

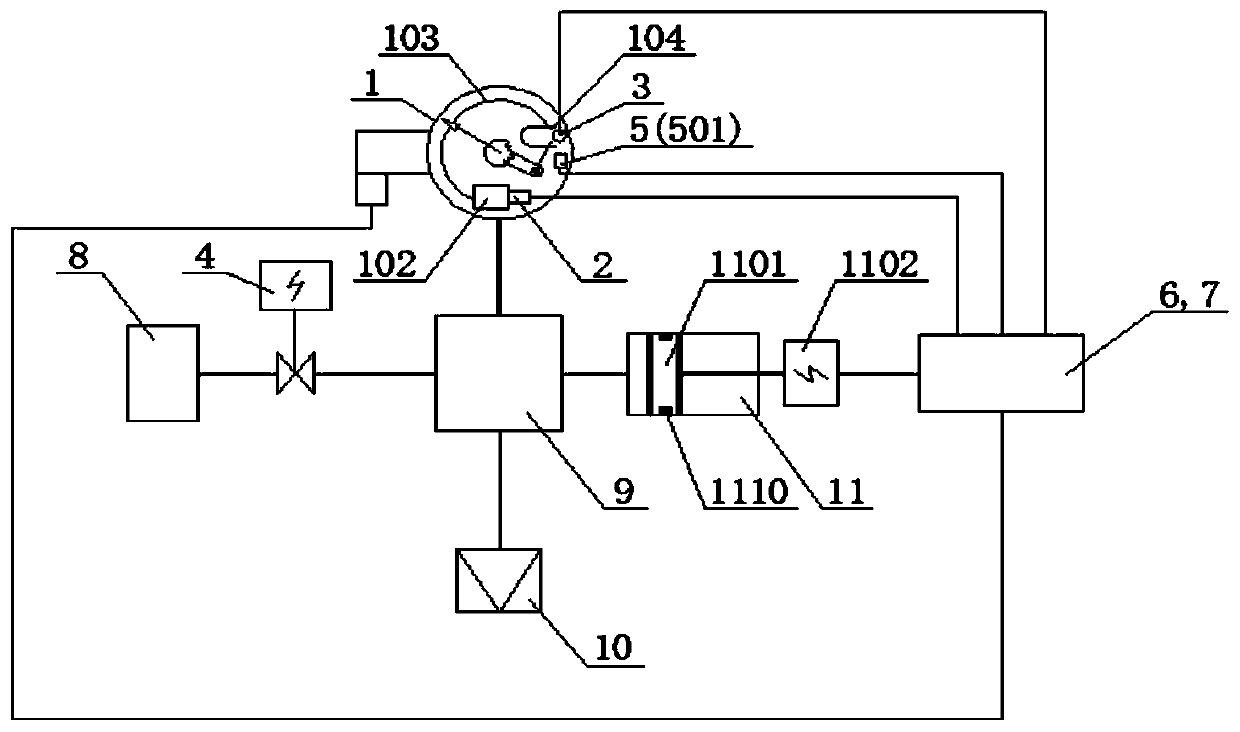

[0175] Such as image 3 As shown, a gas density relay or a gas density monitoring device with an online self-verification function provided by Embodiment 2 of the present invention includes: a gas density relay body 1, a pressure sensor 2, a temperature sensor 3, a valve 4, and a temperature adjustment mechanism 5. On-line verification contact signal sampling unit 6, intelligent control unit 7, multi-way joint 9, air supply interface 10, pressure adjustment mechanism 11. One end of the valve 4 is sealingly connected to an electrical device 8 , and the other end of the valve 4 is connected to a multi-way joint 9 . The gas density relay body 1 is installed on the multi-way joint 9; the pressure sensor 2 and the temperature sensor 3 are arranged on the gas density relay body 1, and the pressure sensor 2 is connected with the gas density relay body 1 on the gas path; the temperature adjustment The mechanism 5 is set on the density relay body 1; the temperature adjustment mechanis...

Embodiment 3

[0181] Such as Figure 4 As shown, the third embodiment of the present invention provides a gas density relay with an online self-verification function, including: a gas density relay body 1, a first pressure sensor 21, a second pressure sensor 22, a first temperature sensor 31, a second pressure sensor 2. Temperature sensor 32, temperature adjustment mechanism 5, online verification contact signal sampling unit 6, intelligent control unit 7, multi-way joint 9, air supply interface 10, self-sealing valve. One end of the self-sealing valve is sealed and connected to electrical equipment, and the other end of the self-sealing valve is connected to the multi-way joint 9 . The gas density relay body 1, the second pressure sensor 22, the second temperature sensor 32, the temperature adjustment mechanism 5, and the gas supply interface 10 are set on the multi-way joint 9; the first pressure sensor 21 and the first temperature sensor 31 are set on the gas density On the relay body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com