Capacity rapid recovery method for lead-acid storage battery

A lead-acid battery, rapid recovery technology, applied in the direction of lead-acid battery, acid electrolyte, secondary battery charging/discharging, etc., can solve the problems of unsatisfactory repair effect, complicated repair method, substandard capacity, etc., and achieve convenient repair method. , Shorten the repair time, and the effect of short time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

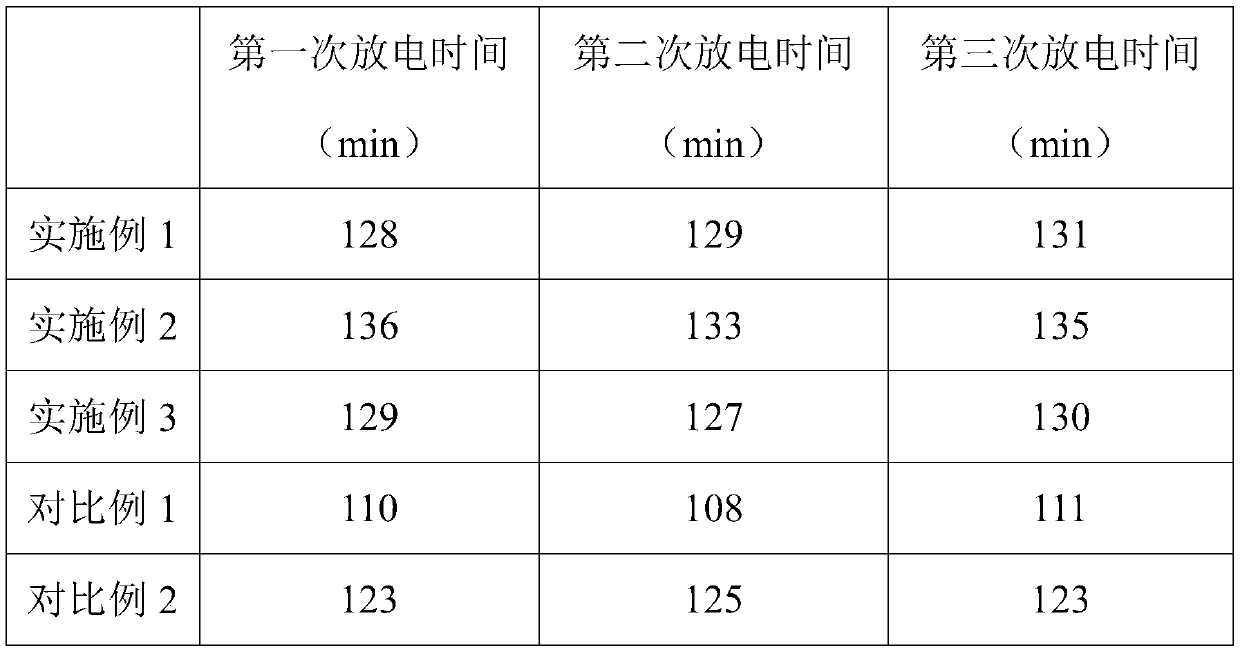

Examples

Embodiment 1

[0022] A kind of lead-acid storage battery capacity recovery method that the present invention proposes, comprises the following steps:

[0023] S1. Raw materials for preparing functional repair fluid: by weight, including a density of 1.32g / cm 3 80 parts of sulfuric acid electrolyte, 0.02 parts of sodium sulfate, 0.15 parts of erythorbic acid, 0.34 parts of 2-acrylamido-2-methylpropanesulfonic acid, 0.04 parts of tetrabutylammonium chloride; the density is 1.32g / cm3 The sulfuric acid electrolyte is diluted with concentrated sulfuric acid with a density of 1.84g / cm3 and distilled water;

[0024] S2. Preparation of functional repair solution: add the sodium sulfate and tetrabutylammonium chloride prepared in step S1 to the density of 1.32g / cm prepared in step S1 3 In the sulfuric acid electrolyte solution, mix evenly to obtain the repair solution base material; in the dark state, add the isoascorbic acid and 2-acrylamido-2-methylpropanesulfonic acid prepared in step S1 to etha...

Embodiment 2

[0029] A kind of lead-acid storage battery capacity recovery method that the present invention proposes, comprises the following steps:

[0030] S1. Raw materials for preparing functional repair fluid: by weight, including a density of 1.32g / cm 3 86 parts of sulfuric acid electrolyte, 0.03 part of sodium sulfate, 0.17 part of erythorbic acid, 0.28 part of 2-acrylamido-2-methylpropanesulfonic acid, 0.05 part of tetrabutylammonium chloride; the density is 1.32g / cm3 The sulfuric acid electrolyte is diluted with concentrated sulfuric acid with a density of 1.84g / cm3 and distilled water;

[0031] S2. Preparation of functional repair solution: add the sodium sulfate and tetrabutylammonium chloride prepared in step S1 to the density of 1.32g / cm prepared in step S1 3 In the sulfuric acid electrolyte solution, mix evenly to obtain the repair solution base material; in the dark state, add the isoascorbic acid and 2-acrylamido-2-methylpropanesulfonic acid prepared in step S1 to ethanol,...

Embodiment 3

[0036] A kind of lead-acid storage battery capacity recovery method that the present invention proposes, comprises the following steps:

[0037] S1. Raw materials for preparing functional repair fluid: by weight, including a density of 1.32g / cm 393 parts of sulfuric acid electrolyte, 0.04 part of sodium sulfate, 0.18 part of erythorbic acid, 0.22 part of 2-acrylamido-2-methylpropanesulfonic acid, 0.08 part of tetrabutylammonium chloride; the density is 1.32g / cm3 The sulfuric acid electrolyte is diluted with concentrated sulfuric acid with a density of 1.84g / cm3 and distilled water;

[0038] S2. Preparation of functional repair solution: add the sodium sulfate and tetrabutylammonium chloride prepared in step S1 to the density of 1.32g / cm prepared in step S1 3 In the sulfuric acid electrolyte solution, mix evenly to obtain the repair solution base material; in the dark state, add the isoascorbic acid and 2-acrylamido-2-methylpropanesulfonic acid prepared in step S1 to ethanol, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com