A coreless spinning processing method of a large-scale multiple-diameter variable hollow shaft

A processing method and hollow shaft technology, applied in the field of spinning, can solve the problems of high cost, low machining allowance, poor forming quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

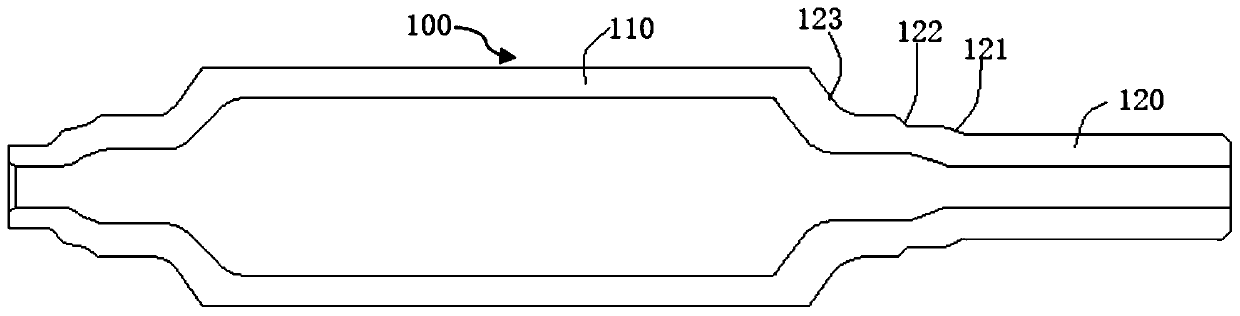

[0049] like figure 1 The hollow shaft 100 to be processed and formed in this embodiment is shown, including a hollow body section 110. One end of the body section 110 is a thin-diameter section 120 with a significantly reduced inner diameter. The thin-diameter section 120 extends for a certain length, and the thin-diameter section Between 120 and the body segment 110 are a plurality of diameter-reducing segments whose outer diameters gradually increase and transition, specifically including a first diameter-reducing segment 121 and a second diameter-reducing segment 122 extending from the thin-diameter segment 120 to the body segments 110 in turn. and the third diameter reduction section 123, each diameter reduction section is an arc-shaped smooth transition section, and a straight extension section is connected between each diameter reduction section, and a step surface distribution is formed between the diameter reduction sections as a whole. figure 1 As shown, the other end...

Embodiment 2

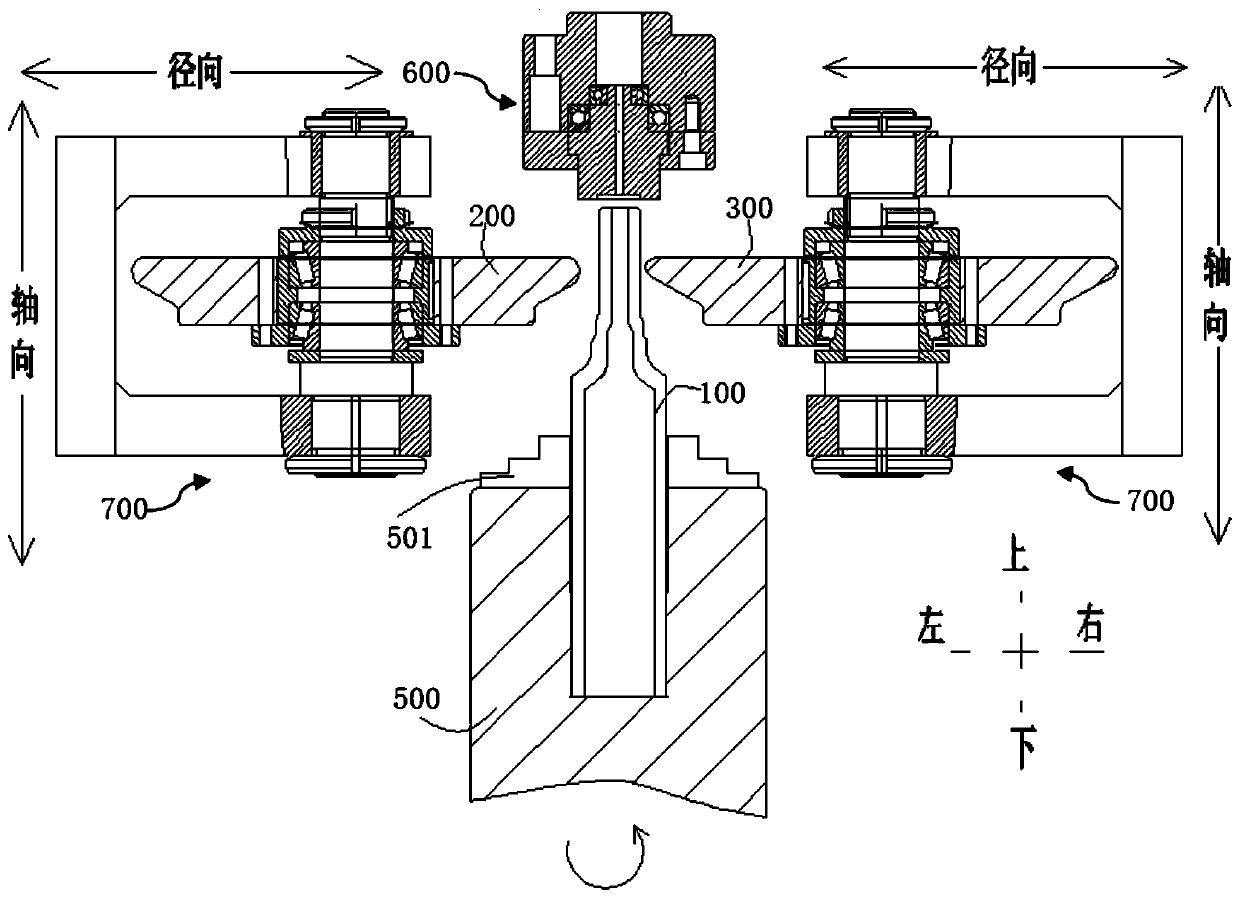

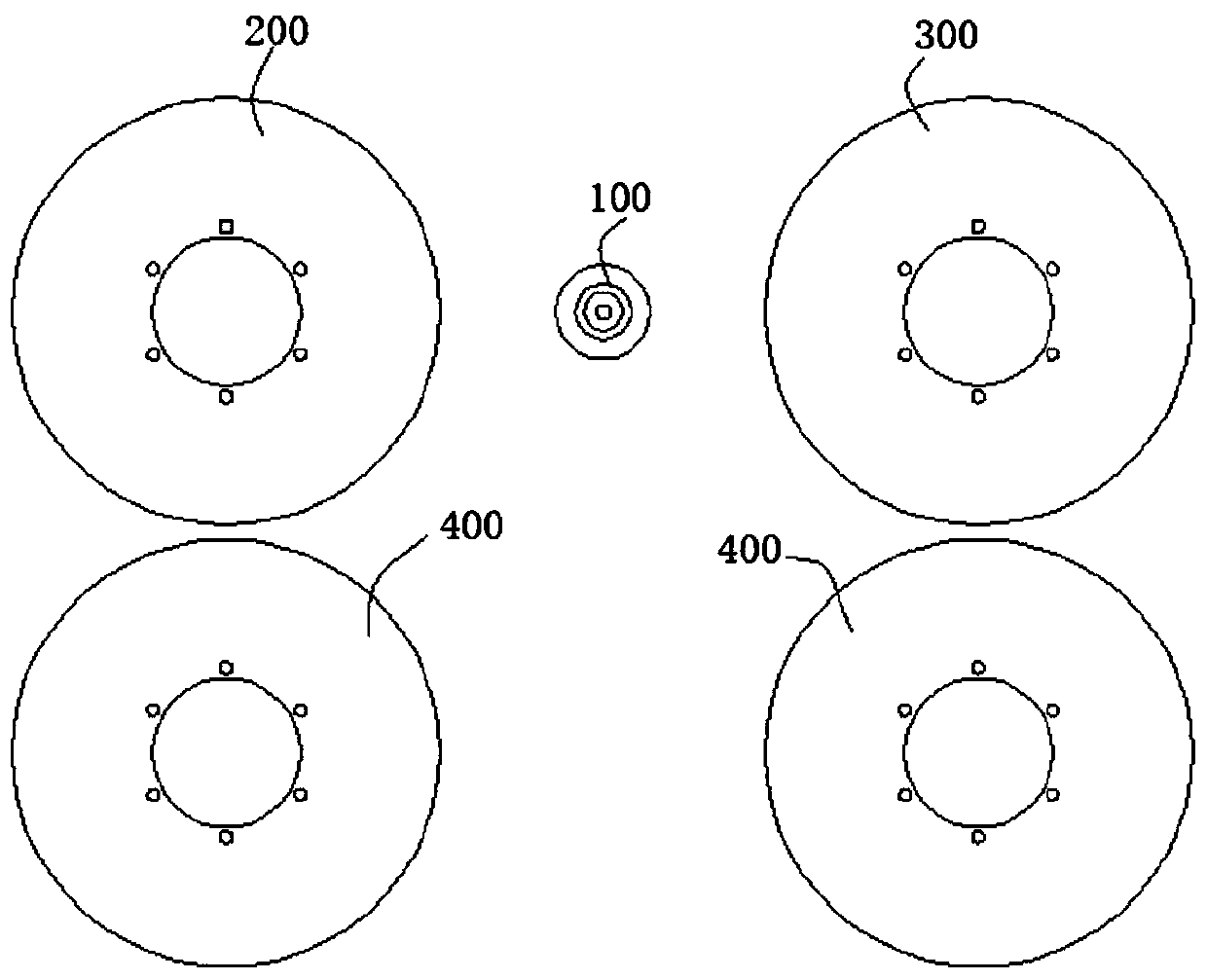

[0063] A coreless spinning processing method for a large-scale multiple variable diameter hollow shaft in this embodiment is basically the same as that in Embodiment 1. Further, the vertical spinning system applied in this embodiment includes a method for clamping workpieces. The lower die unit 500, and the rotary wheel mounting units 700 arranged on both sides of the lower die unit 500. figure 2 As shown, an upper die unit 600 is also provided above the lower die unit 500, wherein the coarse rotary wheel 200 and the shaping rotary wheel 400 are installed on the rotary wheel installation unit 700 on one side, and the rotary wheel installation unit 700 on the other side is installed with The positions of the fine spinning wheel 300 and the shaping spinning wheel 400 , the positions of the coarse spinning wheel 200 and the fine spinning wheel 300 are corresponding, and the positions of the shaping spinning wheels 400 on both sides are corresponding. When in use, the workpiece i...

Embodiment 3

[0067] A coreless spinning processing method for a large-scale, multiple-variable-diameter hollow shaft in this embodiment is basically the same as the above-mentioned Embodiment 2, and further, such as Figure 8 As shown, in this embodiment, the rotating wheel installation unit 700 includes a stand 701, and the upper and lower ends of the stand 701 are respectively provided with mounting plates 702, and the spinning wheel is arranged between the two ends of the mounting plates 702. Specifically, A rotating wheel shaft 710 is arranged between the mounting plates 702 at both ends. The end of the rotating wheel shaft 710 passes through the mounting plate 702 and is fastened by nuts at both ends, and a shaft sleeve 711 is also provided between the rotating wheel shaft 710 and the mounting plate 702. The center of 710 is provided with a wheel base 720, and the bottom of the wheel base 720 is provided with a ring of support ring segments in the axial direction. Bolts are used to fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com