Glass electric smashing table

A technology of glass electricity and power supply, which is applied in glass production, glass manufacturing equipment, glass cutting devices, etc. It can solve the problems of poor power supply effect and inability to maintain a straight line, achieve better cutting effect, reduce glass waste, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with specific embodiments.

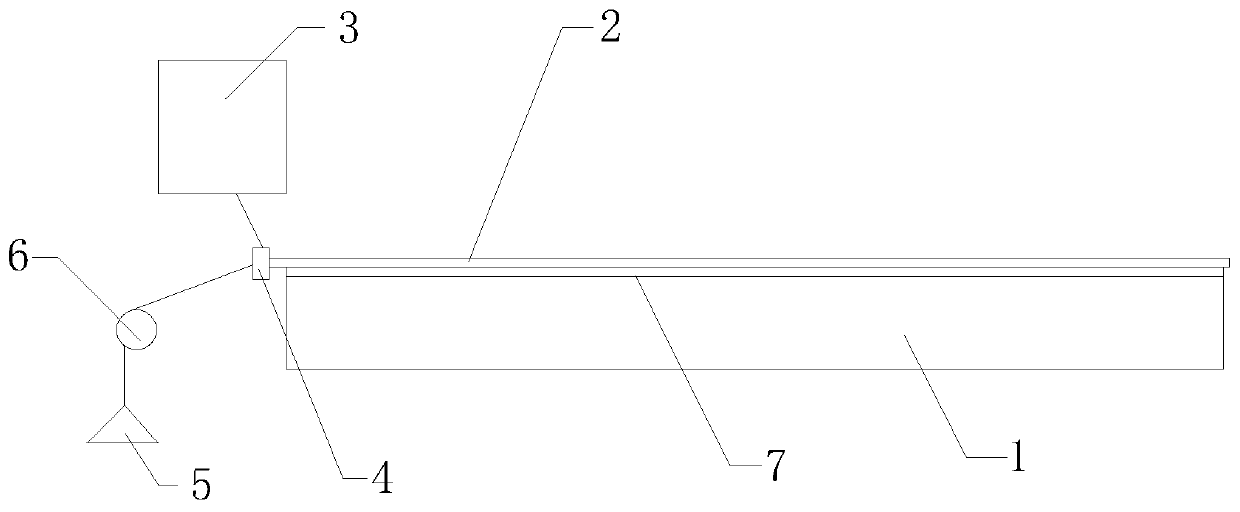

[0012] Such as figure 1 A glass electric smashing platform shown includes an operating platform 1 made of ceramic fiber board and an electric heating device, the electric heating device includes a strip resistance wire 2 and a power supply 3 connected in series with it, and the power supply 3 is fixed by an electric welding machine Adjustable power supply, manual control of working parameters, the resistance wire 2 is set on the operating platform, and the ceramic fiber cloth 7 is set on the operating platform 1, which facilitates the collection and processing of fine glass fragments while insulating heat. The softness of the ceramic fiber cloth 7 enables the resistance wire 2 to sag a part when it is placed on it. When cutting, the glass is smoother, which further improves the flatness of the cut surface and reduces material waste. A counterweight mechanism, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com