Anti-cracking autoclaved aerated concrete building block and production method

A concrete block and autoclaved aeration technology, which is applied in the field of building materials, can solve the problems such as the need to strengthen the waterproof performance and the poor crack resistance, and achieve the effects of good heat preservation, increased stability and enhanced crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

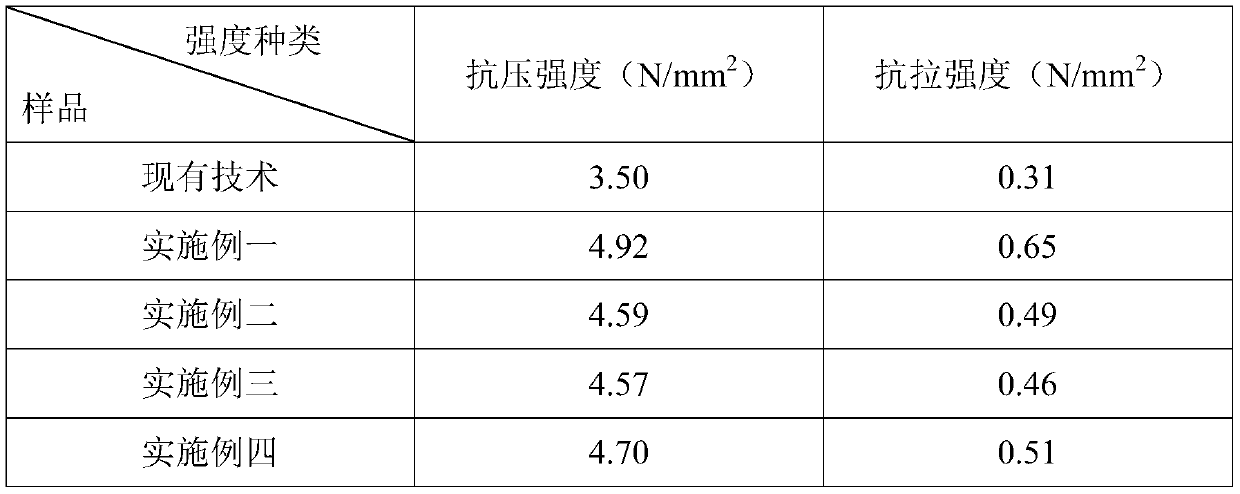

Examples

Embodiment 1

[0037] The crack-resistant autoclaved aerated concrete block in this embodiment is composed of a block body and an anti-crack fiber cloth embedded in the block body. The block body is made of the following raw materials: raw materials include water and materials, According to parts by weight, water is 50 parts; according to parts by weight, the materials include 35 parts of quicklime, which is produced by Jiande Xin'an Jiang Yonghe Plastic Factory, and the state is powder; 25 parts of cement are made by Zhejiang Qianchao Holdings The composite Portland cement produced by the Group Co., Ltd. has a strength grade of 32.5; 15 parts of gypsum are gypsum powder produced by Jinan Runmeite Chemical Co., Ltd.; 15 parts of fly ash are produced by Shijiazhuang Chilin Mineral Products Co., Ltd. Fly ash; 3 parts of anti-cracking fiber, using basalt fiber, the length of the anti-cracking fiber is 15mm, the equivalent diameter is 35μm, the tensile strength is not less than 2169Mpa, and the f...

Embodiment 2

[0055] The crack-resistant autoclaved aerated concrete block in this embodiment is composed of a block body and an anti-crack fiber cloth embedded in the block body. The block body is made of the following raw materials: raw materials include water and materials , according to parts by weight, water is 55 parts; according to parts by weight, the material includes 33 parts of quicklime, which adopts the quicklime produced by Jiande Xin'an Jiang Yonghe Plastic Factory, and the state is powdery; 27 parts of cement, adopts Zhejiang Qianchao Composite Portland cement produced by Holding Group Co., Ltd., with a strength grade of 32.5; 13 parts of gypsum, gypsum powder produced by Jinan Runmeite Chemical Co., Ltd.; 18 parts of fly ash, produced by Shijiazhuang Chilin Mineral Products Co., Ltd. fly ash; 4 parts of anti-cracking fiber, using monofilament polypropylene fiber, the length of anti-cracking fiber is 20mm, the equivalent diameter is 50μm, the tensile strength is not less than...

Embodiment 3

[0059] The crack-resistant autoclaved aerated concrete block in this embodiment is composed of a block body and an anti-crack fiber cloth embedded in the block body. The block body is made of the following raw materials: raw materials include water and materials , according to parts by weight, water is 55 parts; according to parts by weight, the material includes 30 parts of quicklime, which adopts the quicklime produced by Jiande Xin'an Jiangyonghe Plastic Factory, and the state is powdery; 25 parts of cement, adopts Zhejiang Qianchao Composite Portland cement produced by Holding Group Co., Ltd., with a strength grade of 32.5; 11 parts of gypsum, gypsum powder produced by Jinan Runmeite Chemical Co., Ltd.; 16 parts of fly ash, produced by Shijiazhuang Chilin Mineral Products Co., Ltd. fly ash; 3.5 parts of anti-crack fiber, using monofilament polypropylene fiber, the length of the anti-crack fiber is 20mm, the equivalent diameter is 50μm, the tensile strength is not less than ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com