Method for direct patterned growth of atomic layer transition metal dichalcogenides

A transition metal dichalcogenide, transition metal technology, applied in metal selenide/telluride, chemical instruments and methods, molybdenum sulfide, etc., can solve problems such as changing the inherent properties of TMD monolayers, mask resolution, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The detailed description set forth below in connection with the accompanying drawings is intended as a description of various configurations and is not intended to represent the only configurations in which the concepts described herein may be practiced. The detailed description includes specific details for the purpose of providing a thorough understanding of various concepts. It will be apparent, however, to one skilled in the art that these concepts may be practiced without these specific details.

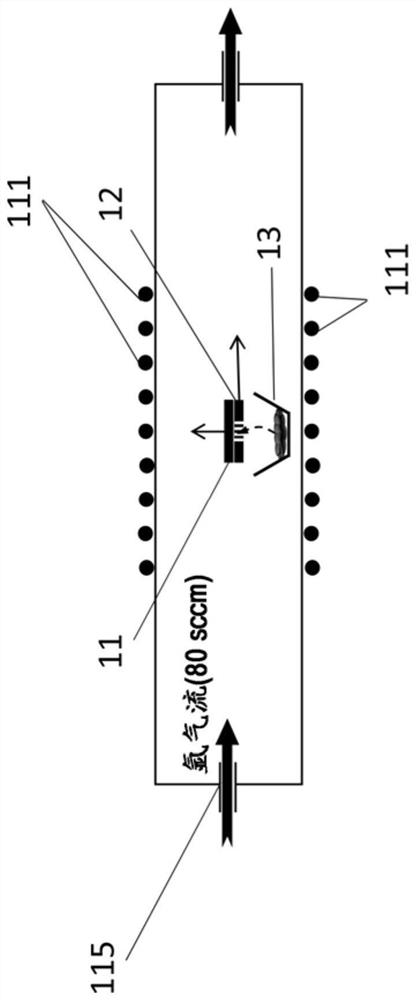

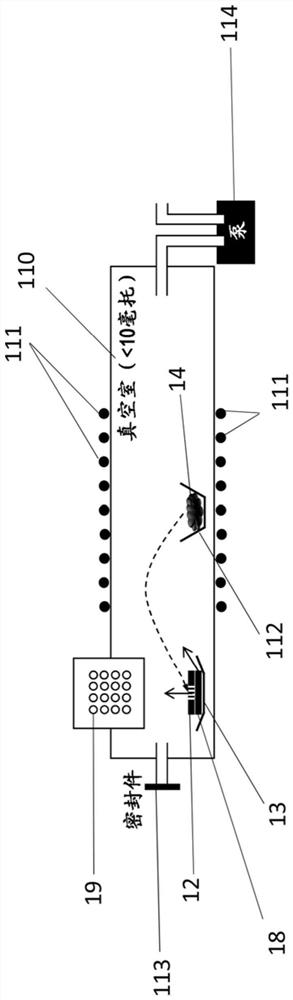

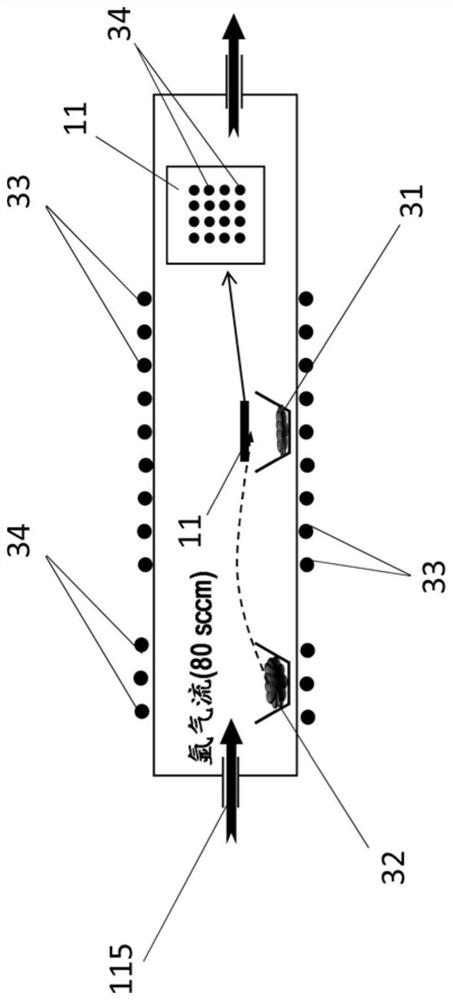

[0012] This disclosure describes a newly developed method for molybdenum disulfide (MoS 2 ) and / or direct patterned growth of atomic layers of other transition metal dichalcogenide materials. Patterned growth has been achieved by using salts as intermediate or template materials. Specifically, the salt can be deposited on the substrate through a mask having a desired pattern. The method leads to atomic layer MoS 2 (or other metal dichalcogenide materials) of the same ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com