Ultra-large orthogonal truss cable beam thermal insulation aluminum alloy combined storage tank and construction method

An aluminum alloy and truss technology, which is applied to the super-large orthogonal truss cable-beam thermal insulation aluminum alloy combined storage tank and construction, storage tank field, can solve the problems of poor thermal insulation effect and small storage tank volume, and achieves short construction period and mechanical properties. Excellent, good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing, the present invention will be further described:

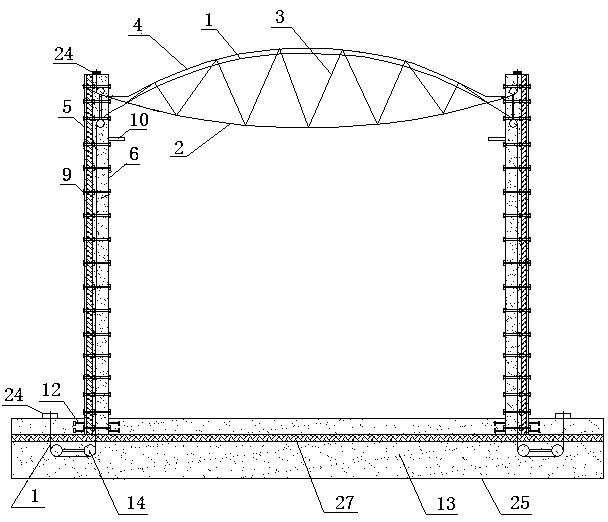

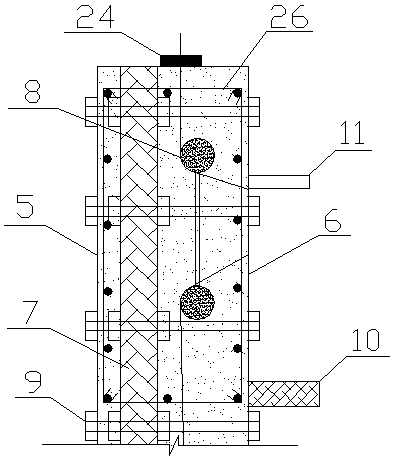

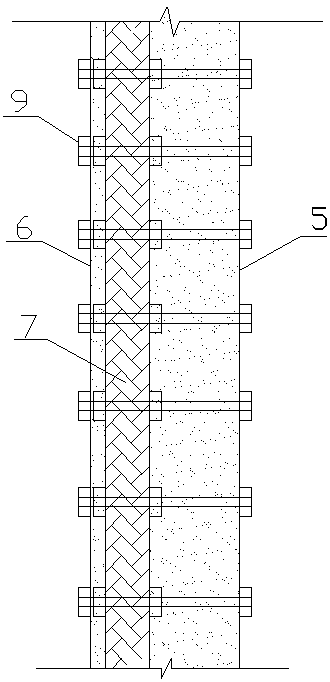

[0041] combine Figure 1-Figure 12 As shown, this super-large orthogonal truss cable-beam thermal insulation aluminum alloy composite storage tank includes a tank roof, a tank wall, and a tank bottom 25. The tank roof adopts an orthogonal truss cable-beam structure, and a roof panel 4 is laid on the orthogonal truss cable-beam structure; The tank wall is composed of an inner panel 6, an outer panel 5, an interlayer insulation panel 7, and ordinary concrete. Ordinary concrete is filled in layers, see figure 2 , the top of the tank wall is provided with a reinforced concrete ring beam 26, and a vertical ring-shaped steel pipe active powder concrete composite truss 8 is arranged in the ring beam for the conversion direction of the cable; the tank bottom 25 is composed of an active powder concrete 13 and an insulating layer 27, see Figure 11 , The bottom 25 of the tank is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com