Treatment construction method for continuous collapse and roof fall in small-section steep slope tunnel

A construction method and continuous technology, which is applied in the construction field of continuous landslide and roof fall of small-section steep slope tunnels, can solve the problems of landslide area expansion, surface collapse, and high height of landslide area, so as to ensure safety and construction progress, and weaken the slide The impact force and the effect of improving the support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

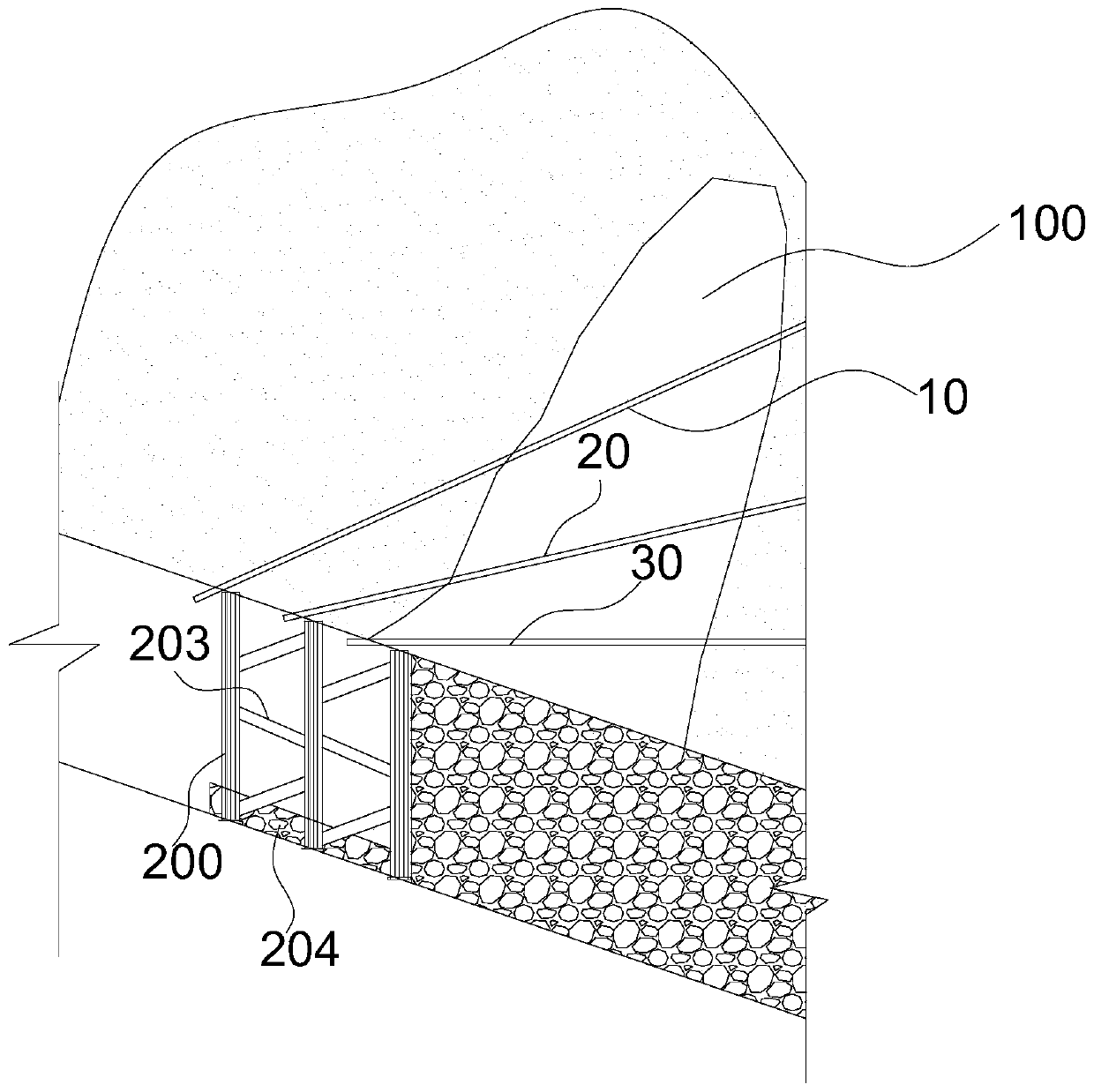

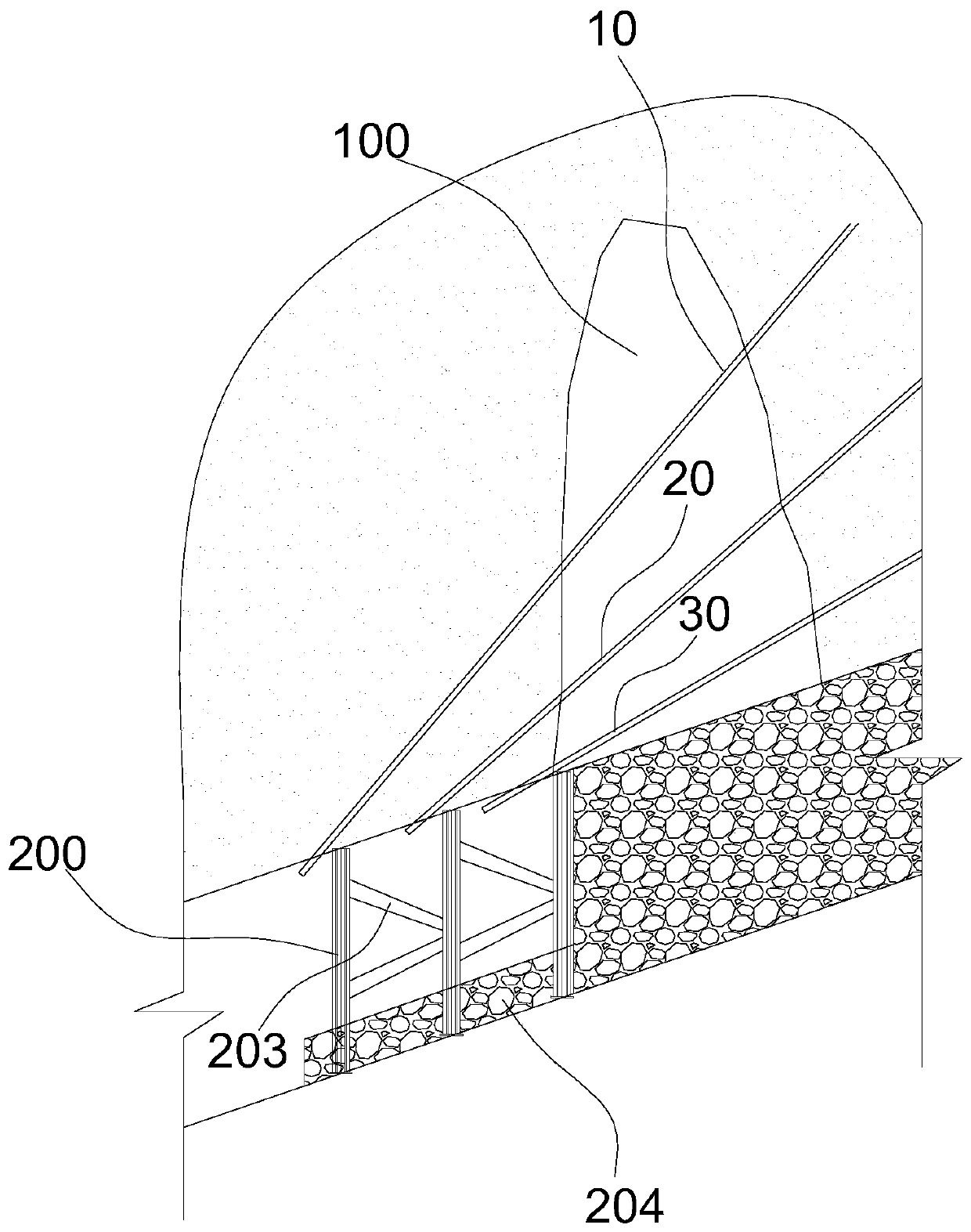

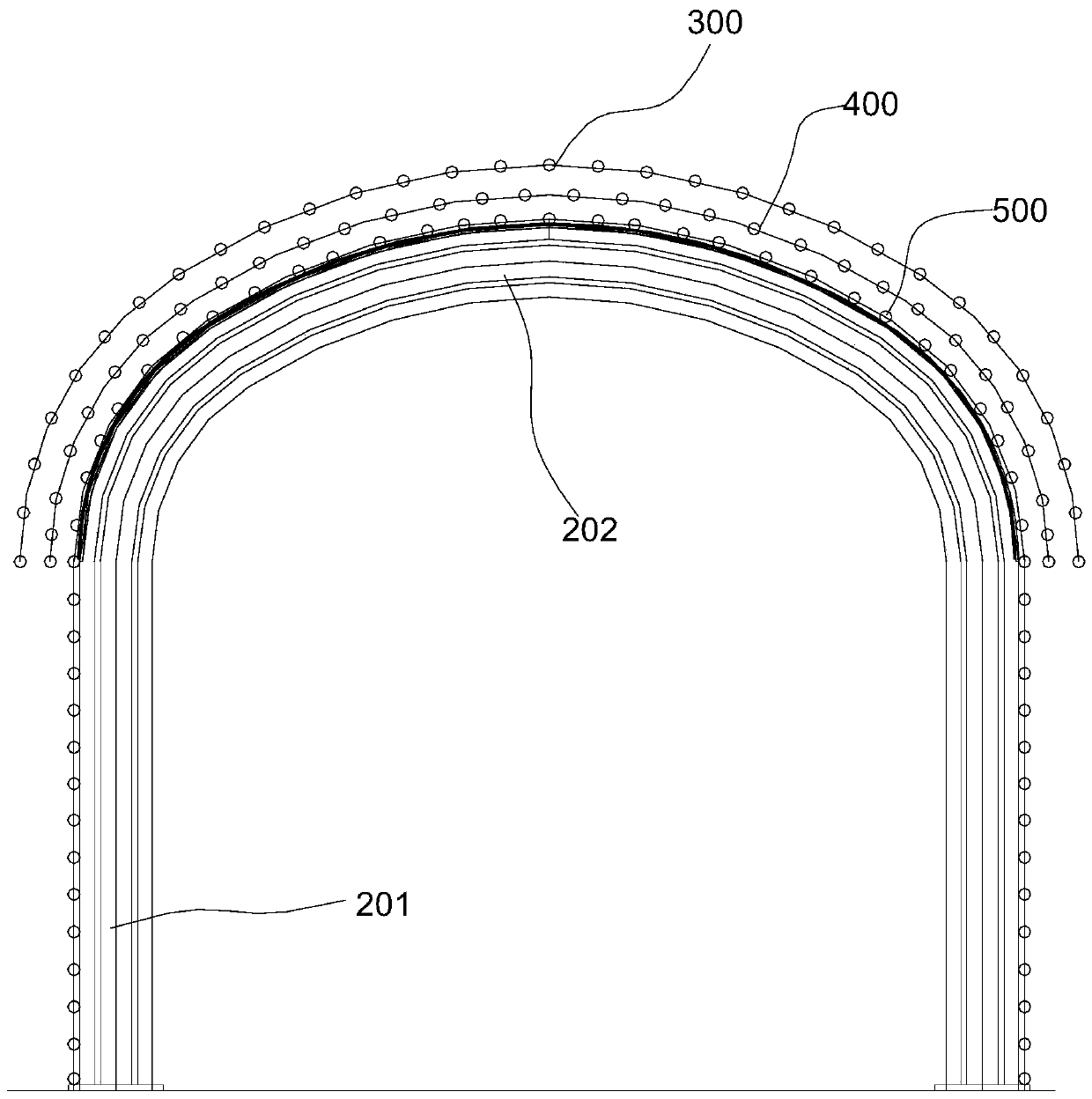

[0025] Such as Figure 5 As shown, since the conventional tunnel collapse area 100 will form a stable cavity, the focus of its treatment is mostly on the backfilling of the collapse cavity and the strengthening of support below; while the rock formation is too broken, there are a large number of fault fracture zones , and under the lubricating effect of groundwater, there will often be continuous collapse and roof fall, which is characterized in that once the collapse occurs, it will continue to expand until the surface collapses and the overall collapse occurs, and the consequences are more serious. In addition, in view of the limited space of small-section mine tunnels and the influence of long and steep slopes, it further increases the difficulty of landslide disaster management for persistent high-roof landslides. In order to solve this type of pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com