Replaceable sputtering-resistant vacuum cavity for electric thruster ignition test and assembly method

A technology of vacuum chamber and ignition test, which is used in the testing of machine/structural components, instruments, measuring devices, etc., can solve the problems of long production time, high production cost, complex structure, etc., and achieves low manufacturing cost and replacement of titanium plates. Convenience and uniform specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

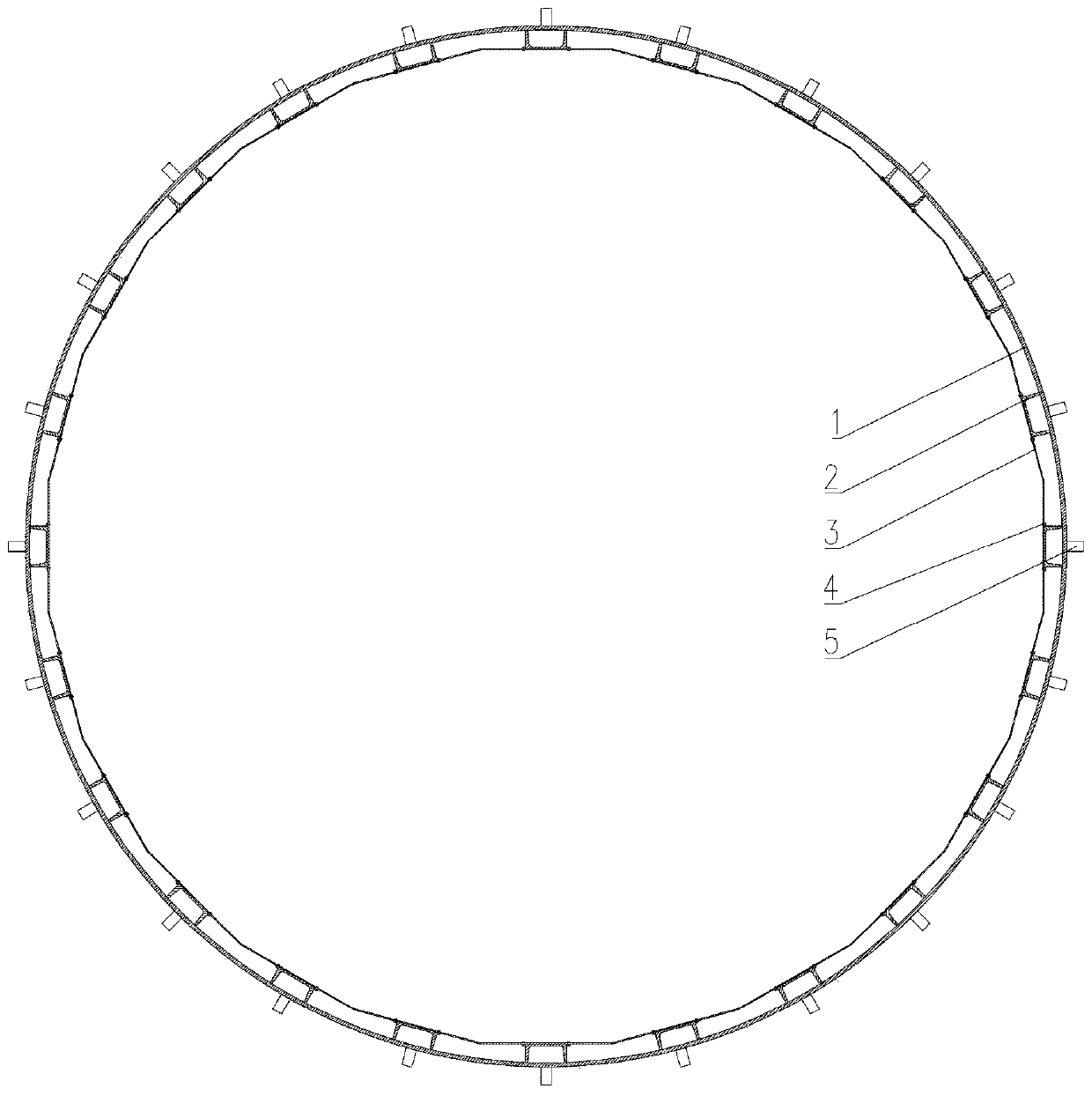

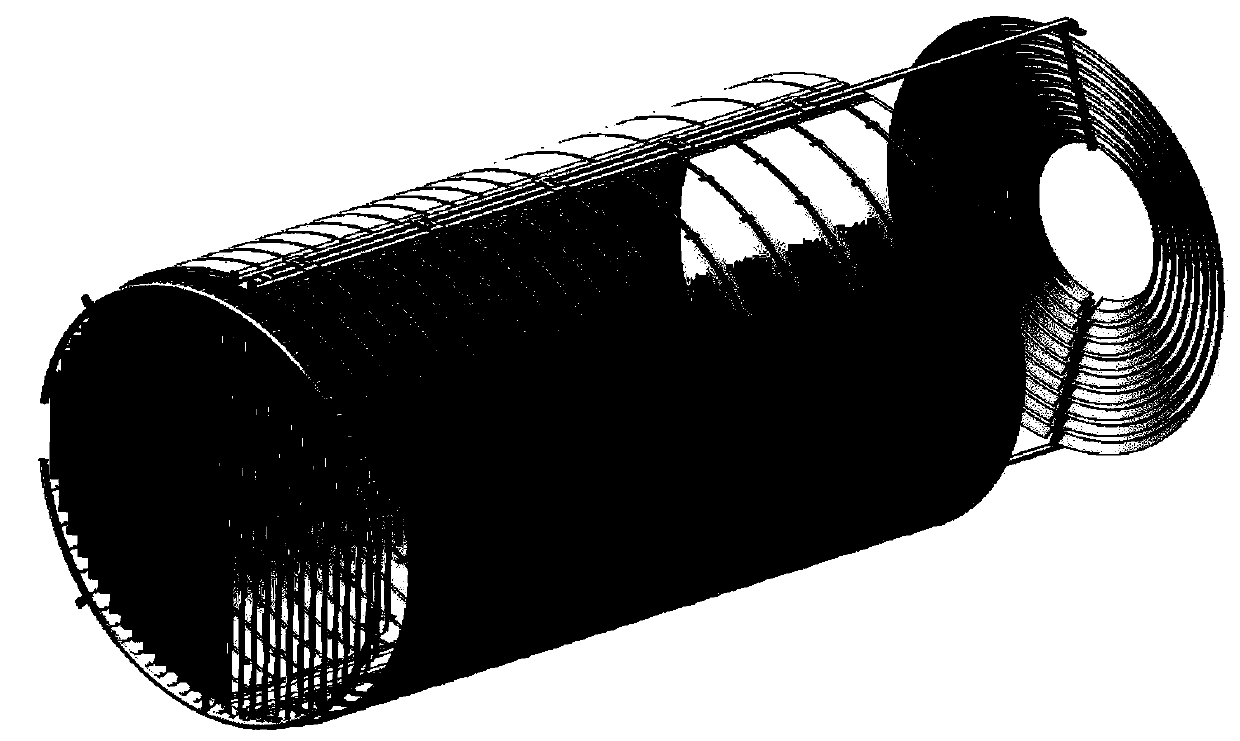

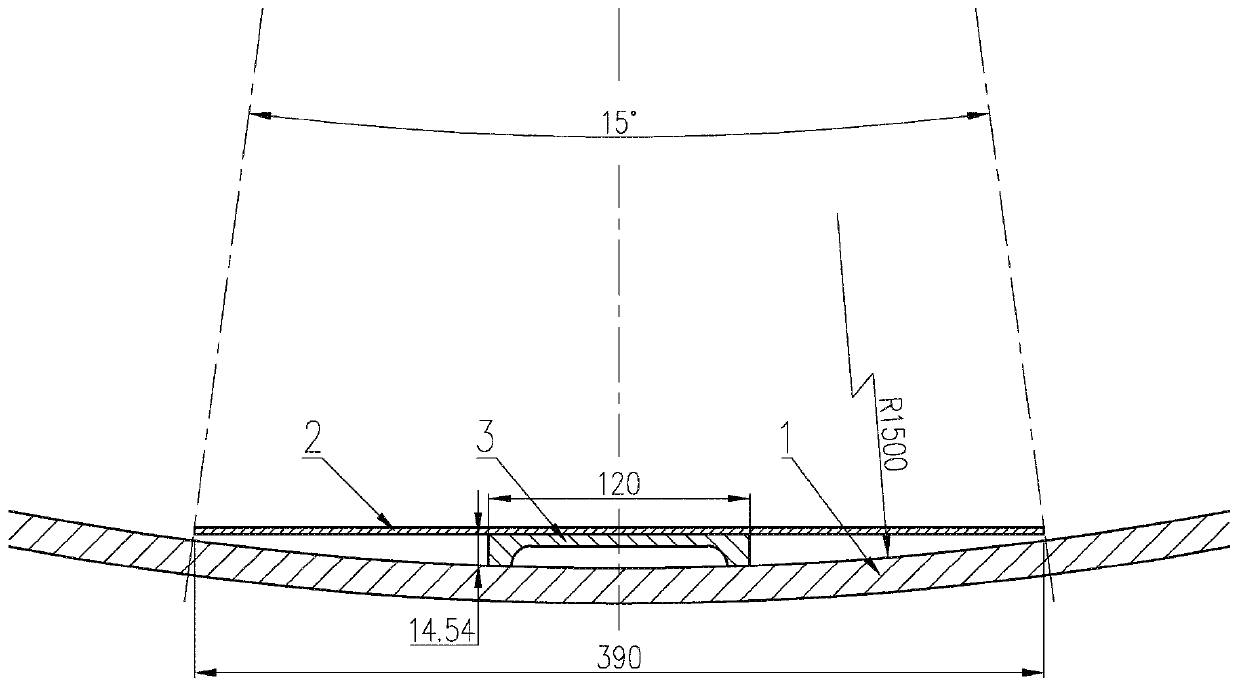

[0062] A replaceable sputtering-resistant vacuum chamber product for electric thruster ignition test has a total length of 6m, and the inner diameter of the vacuum chamber 1 is 3m. The sputter-resistant protective plate 2 completely covers the inner surface of the straight section of the vacuum chamber 1. The sputter-resistant protective plate 2 is spliced by more than one hundred titanium plates, and the structural dimensions of each titanium plate are exactly the same. The channel steel 3 is welded and installed on the inner wall of the vacuum cavity 1, and a plurality of cold water flow channels 4 are evenly distributed circumferentially along the axial direction. The anti-sputter protection plate 2 divides the vacuum chamber 1 into 24 units in the circumferential direction, and each unit has a central angle of 15 degrees. The chord length of a central angle of 15 degrees at a radius of 1.5m is 391.6mm. Due to the need to reserve a certain space for the heat dissipation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com