Waste salt slag harmless and resource utilization system based on Internet of Things

A waste salt slag, harmless technology, applied in the field of Internet of Things, can solve the problems of large land occupation, secondary environmental hazards, high cost, etc., and achieve the effects of accelerating melting, improving flue gas flow, and improving mobile stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

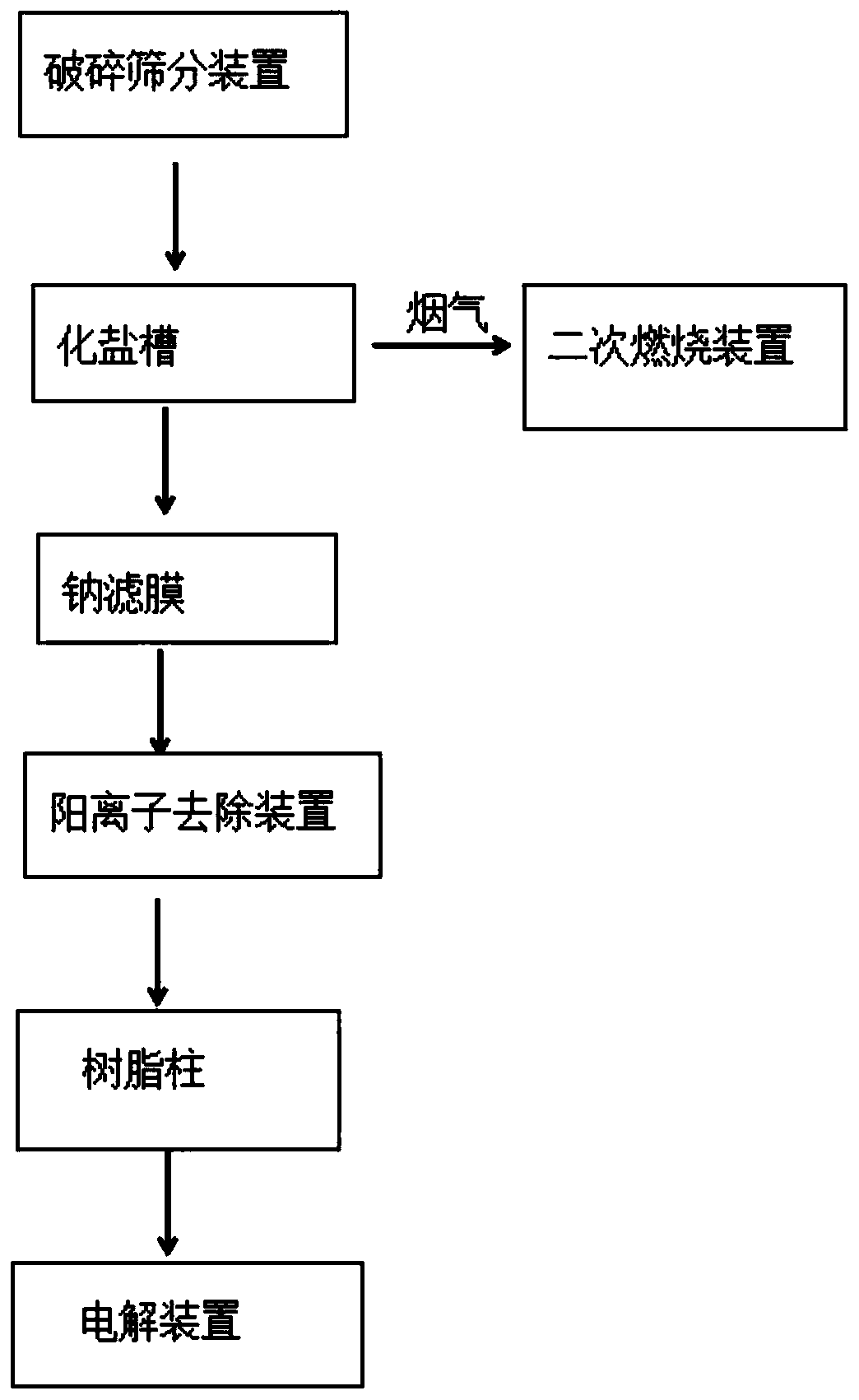

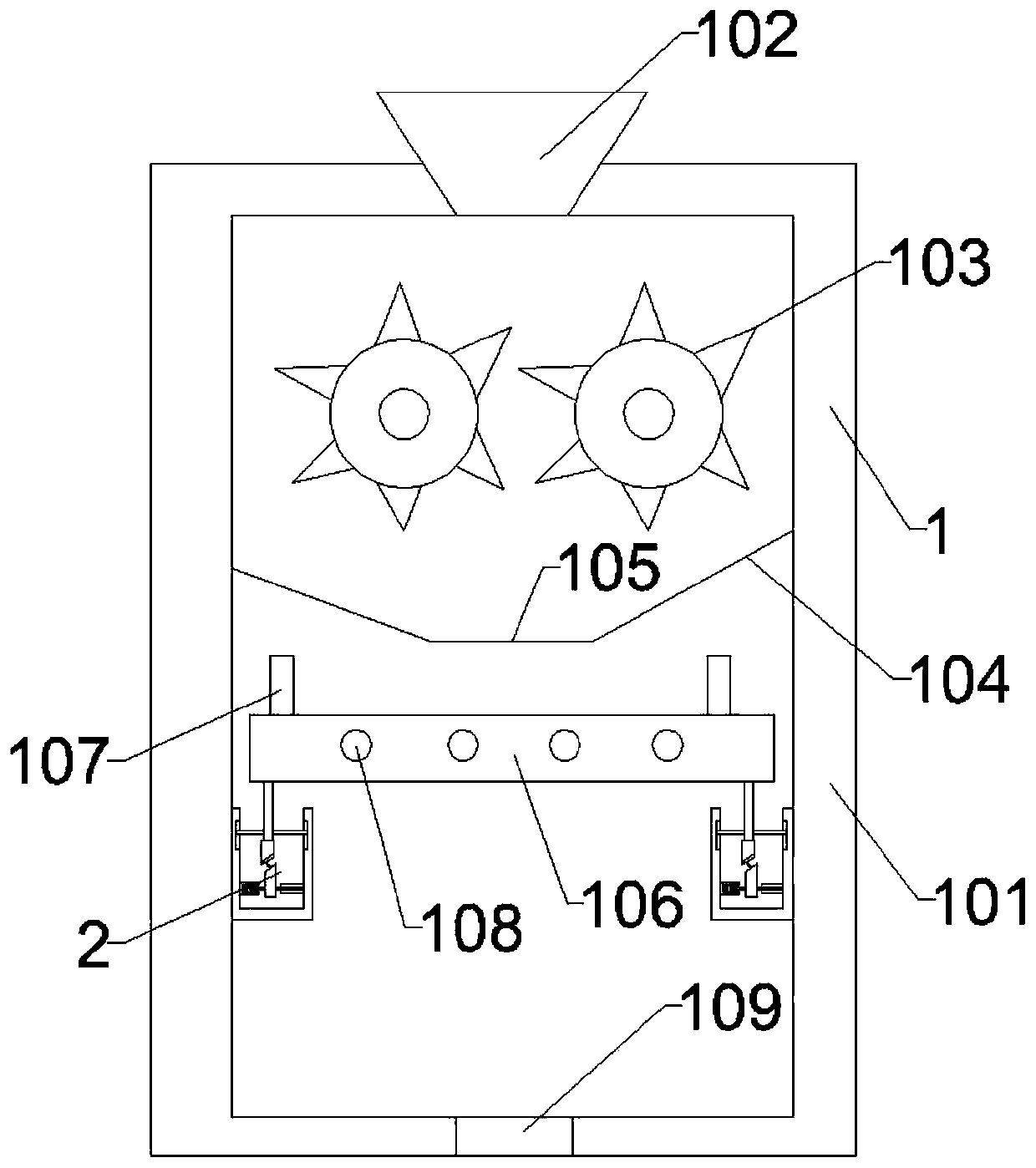

[0031] see Figure 1-2 , in the present invention, a high-efficiency waste salt slag harmless and resource utilization device includes a crushing and screening device 1, and the crushing and screening device 1 first crushes the waste salt slag and then sieves it according to the particle size;

[0032] see image 3 , the crushing and screening device 1 includes a crushing and screening box 101, the upper part of the crushing and screening box 101 is provided with a feed inlet 102, the crushing and screening box 101 is provided with a crushing roller 103, and the bottom of the crushing roller 103 is provided with a collecting plate 104, two A collection plate 104 forms a collection hopper 105, the bottom of the collection hopper 105 is provided with a sieve plate 106, the bottom of the sieve plate 106 is symmetrically provided with a vibrating mechanism 2, the top of the sieve plate 106 is provided with a dividing plate 107, and the discharge port of the hopper 105 is located a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com