An electromechanical drilling device driven by a single motor

A technology of single-motor drive and drilling device, applied in the direction of drive device, feeding device, positioning device, etc., can solve the problems of affecting working life, high cost, high energy consumption, improve quality and efficiency, good damping and buffering effect, Easy to disassemble and replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

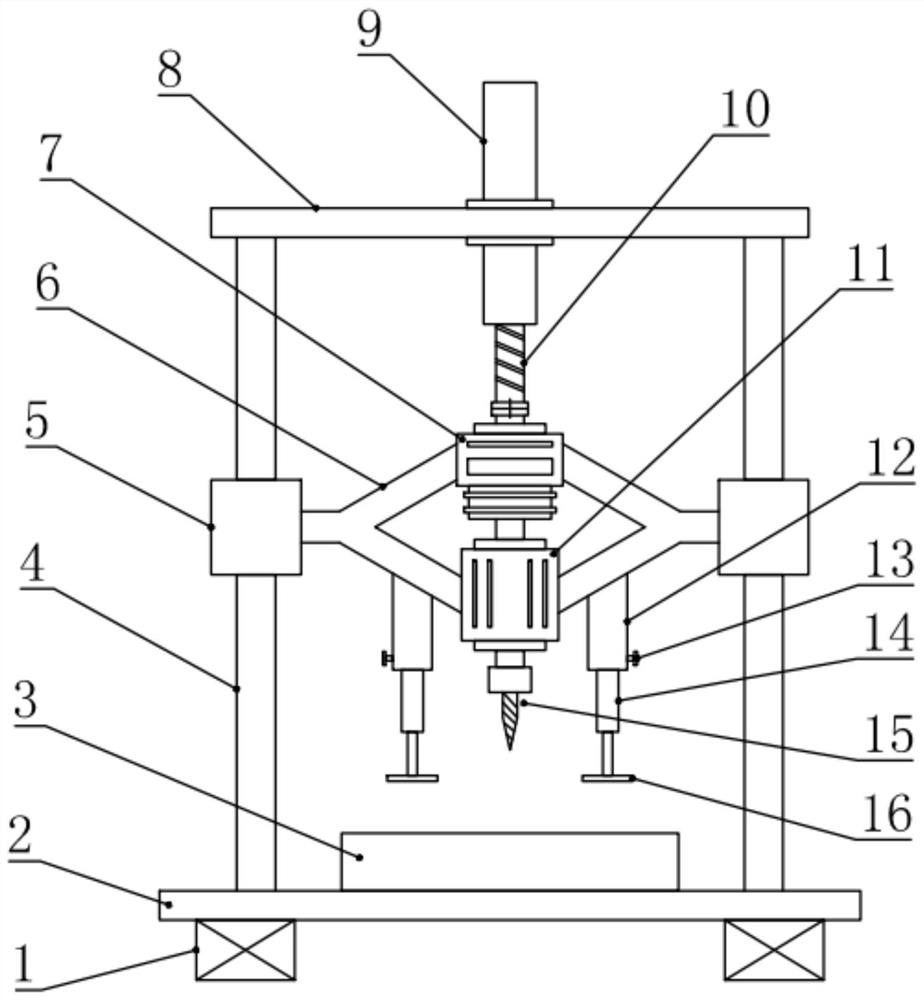

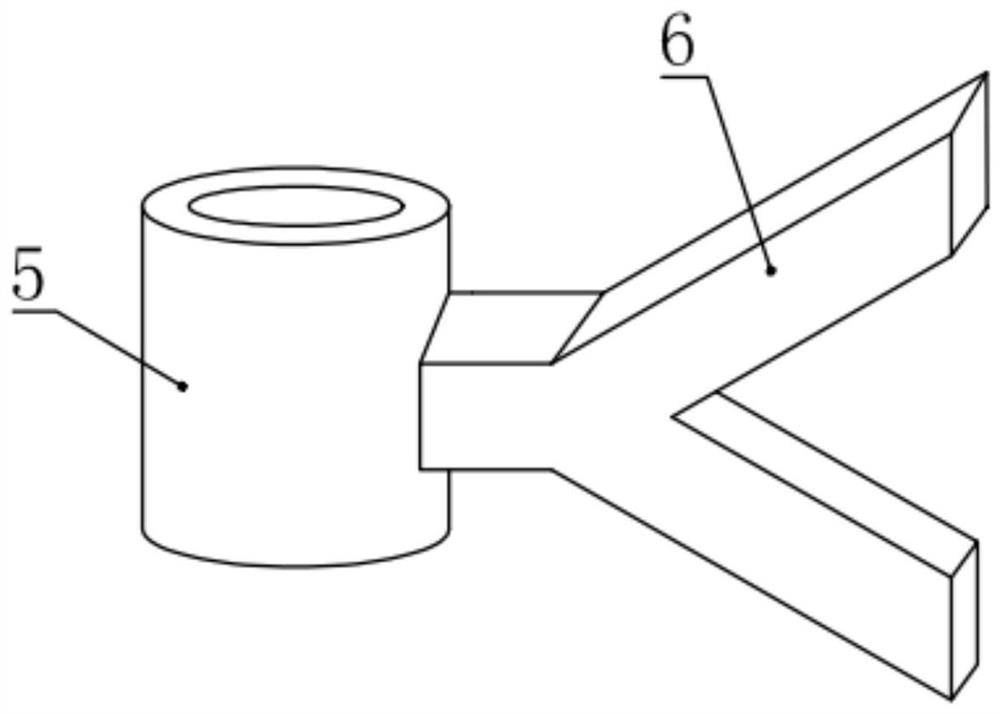

[0028] see figure 1 and 3 , in an embodiment of the present invention, a single-motor-driven electromechanical drilling device includes a floor base 2, a processing table 3, a column 4 and a top plate 8, the processing table 3 is installed and fixed on the bottom plate base 2, and the top plate 8 and A column 4 is respectively installed and fixed on both sides between the floor seats 2, and a biaxial extension motor 11 is arranged between the two columns 4, and a speed changer 7 is arranged on the upper side of the biaxial extension motor 11, and a biaxial extension motor 11 The upper motor shaft 25 is connected to the input shaft of the transmission 7, and the upper output shaft of the transmission 7 is connected and fixed to the threaded rod 10. The threaded cylinder 9 is installed and fixed on the top plate 8, and the threaded rod 10 and the threaded cylinder 9 are threadedly connected. A Y-shaped support 6 is installed and fixed on both sides of the speed changer 7 and th...

Embodiment 2

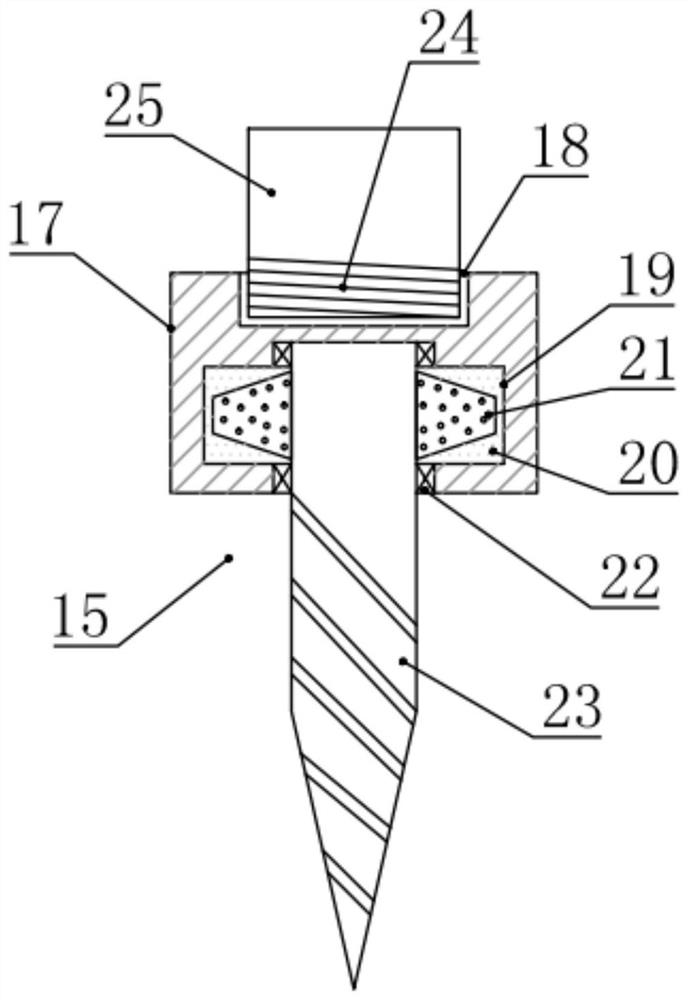

[0033] see figure 2 , the difference between this embodiment and embodiment 1 is:

[0034] In this embodiment, the drill rod assembly 15 includes a housing 17 and a drill rod 23, the inner side of the housing 17 is provided with a cavity 19, the lower side of the housing 17 is rotatably mounted with a drill rod 23, and the drill rod 23 is The upper end extends to the top of the cavity 19, and the drill rod 23 is sealed and rotated with the housing 17 at the top and bottom of the cavity 19 through the bearing 22, and the drill rod 23 in the cavity 19 is installed and fixed in the upper direction A plurality of porous damping plates 21, the porous damping plate 21 is an isosceles trapezoidal structure, the porous damping plate 21 is arranged perpendicular to the surface of the drill pipe 23, the lower bottom of the porous damping plate 21 is fixed on the drill pipe 23, the hollow The cavity 19 is filled with a damping liquid 20, which is a shear thickening liquid or glycerin, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com