Method for preventing natural latex product from blooming

A technology for natural latex and dairy products, applied in the field of latex product production technology, can solve the problems of difficult screening of auxiliaries, complex process methods, and difficulty in large-scale use, etc., and achieve the effects of reducing volatilization of water, alleviating phenomena, and alleviating frost spray.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] Specifically, the preparation method comprises the following steps:

[0045] (1) Pre-vulcanization: Take natural rubber latex, vulcanizing agent, anti-aging agent and accelerator by weight and put them into the vulcanization tank, slowly heat up to 50-70°C within 1-3h for pre-vulcanization, then keep warm for 1-3h, and cool After reaching 25-35°C, add an activator and a stabilizer, stir evenly, leave for 30-60 hours to obtain pre-vulcanized latex, and adjust the concentration of the pre-vulcanized latex to 50-65wt% with ammonia water;

[0046] (2) Molding: casting method, dipping method or extrusion method:

[0047] The casting method comprises the following steps: pour the natural rubber latex into the mold, place it at room temperature for 12-24 hours, place it in an oven at 40-60°C, and demould;

[0048] The impregnation method includes the following steps: take the impregnation mold and place it in an oven until the surface temperature is 55-65°C, dip the coagulant...

Embodiment 1

[0053] From the vulcanization workshop of natural latex gloves, a total of 3 samples of the same batch of natural latex gloves that had just completed the vulcanization process were collected, and after being placed in the laboratory for 1 min, two gloves were started to be processed by the method of the present invention. Put one glove unfolded into a ziplock bag (a plastic bag with a sealed zipper, with good airtightness) and seal it; the other glove is completely wrapped and sealed with PE plastic wrap on the surface of the glove; the third glove sample does not do the aforementioned deal with. Spread the above three gloves together in a laboratory dark box (60cm*100cm*30cm), keep the temperature in the dark box at 25°C, and take them out after 3 days. Then, the ziplock bag and the plastic wrap were removed respectively to obtain 3 comparison samples. The 3 comparative samples were placed on the window sill with visible sunlight in the south for 3 months and then observed....

Embodiment 2

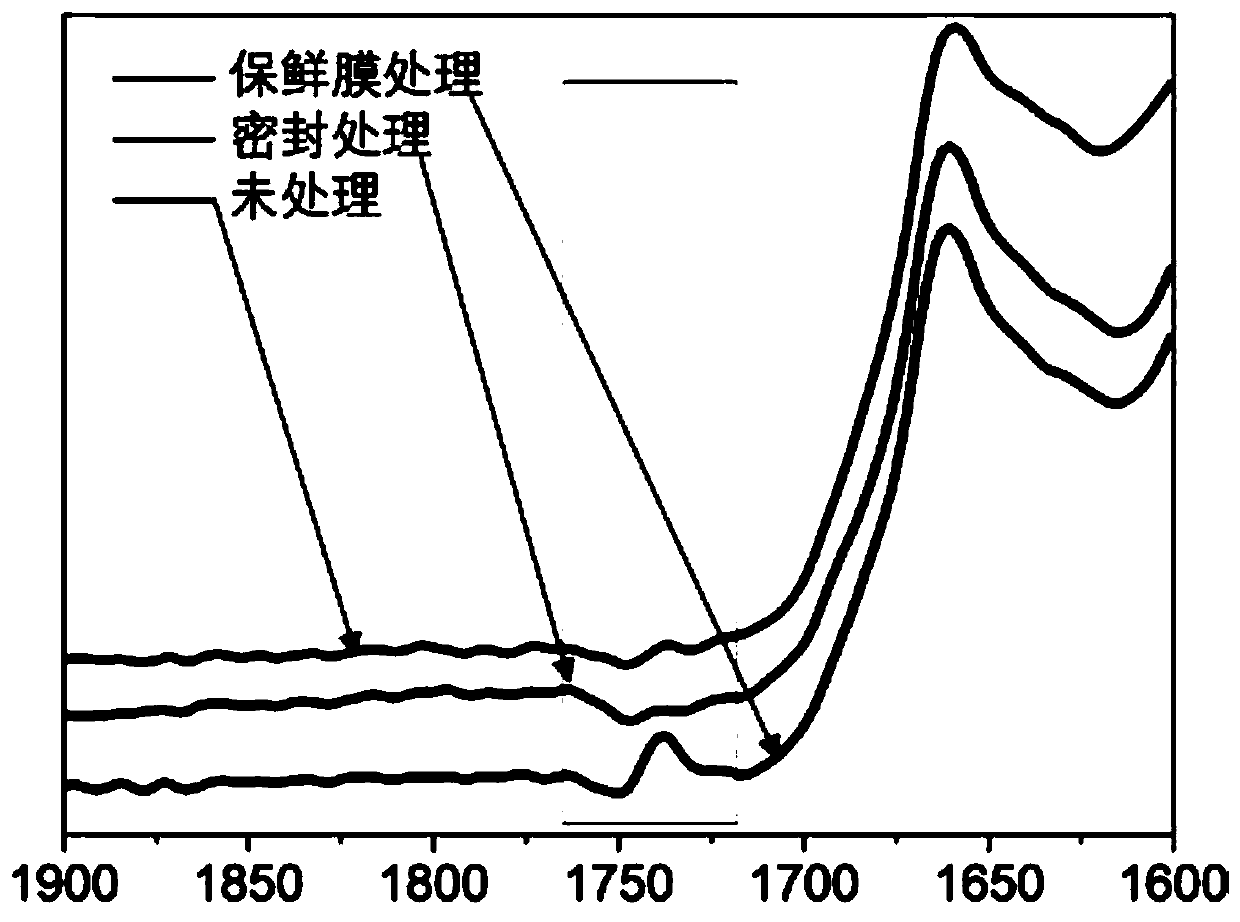

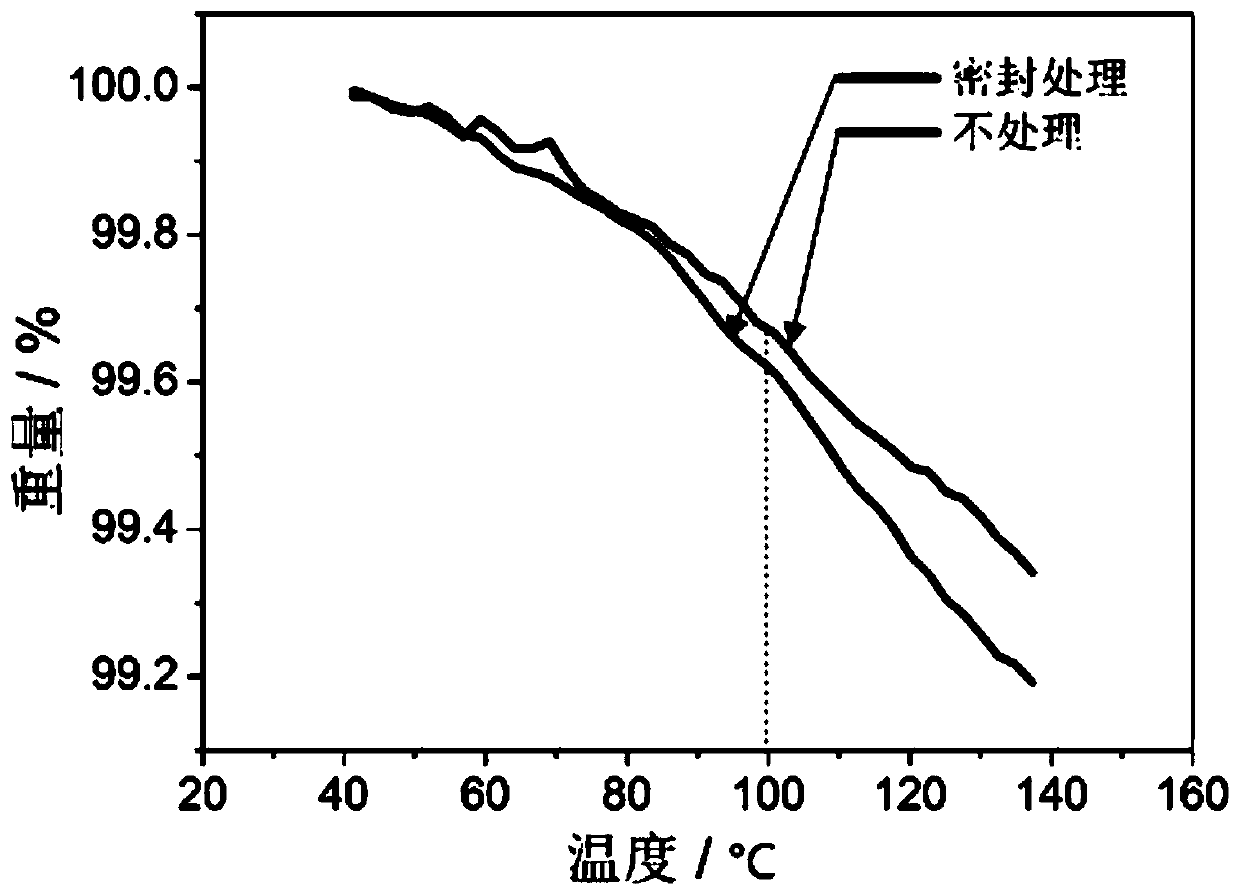

[0056] From the vulcanization workshop of natural latex gloves, a total of 3 samples of the same batch of natural latex gloves that had just completed the vulcanization treatment were collected, and after being placed in the laboratory for 1 min, two gloves were started to be processed by the method of the present invention. Put one glove unfolded into a ziplock bag (a plastic bag with a sealed zipper, with good airtightness) and seal it; the other glove is completely wrapped and sealed with PE cling film on the surface of the glove, and the third glove sample does not do the above deal with. Spread the above three gloves together in a laboratory dark box (60cm*100cm*30cm), keep the temperature in the dark box at 40°C, and take it out after 2 days. Then, the ziplock bag and the plastic wrap were removed respectively to obtain 3 glove samples to be tested. Total reflection infrared analysis scans were performed on the surfaces of these 3 glove samples. The result is as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com