Preparation method of forward osmosis emergency drinking water bag prepared based on layer-by-layer self-assembly method

A layer-by-layer self-assembly and forward osmosis technology, applied in the field of environmental engineering, can solve the problems of residual and non-environmentally friendly organic solvents, and achieve the effects of improved separation performance, rich film-forming materials, and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

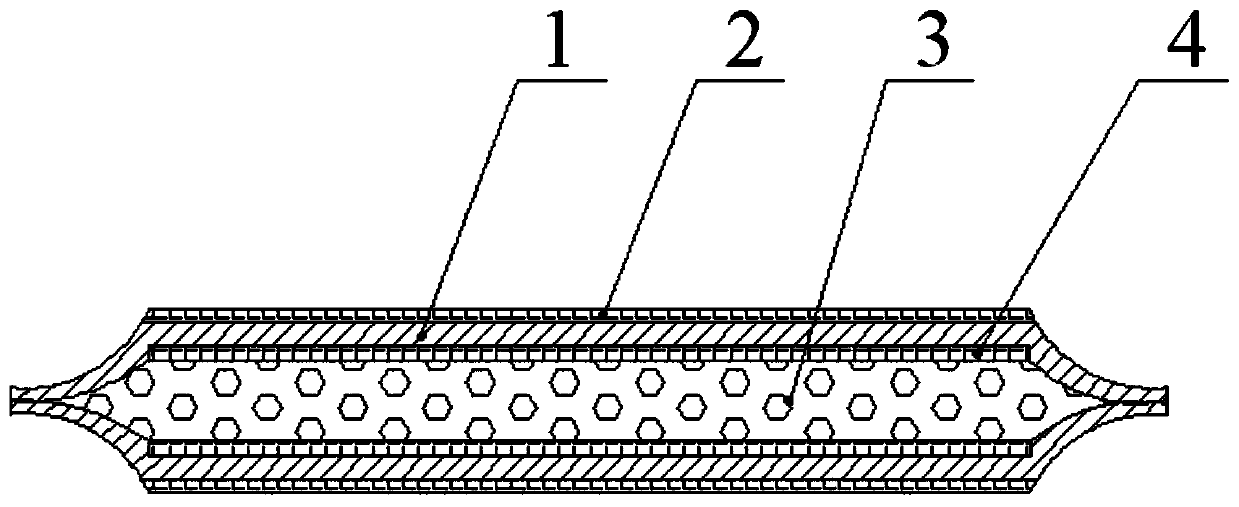

[0026] A method for preparing a forward osmosis emergency drinking water bag based on a layer-by-layer self-assembly method. The drinking water bag is made by sealing two forward osmosis membranes 1, and the water bag composed of forward osmosis membranes is filled with a draw liquid 3. The forward osmosis membrane is prepared by a layer-by-layer self-assembly method. The outer side of the water bag is the active layer 2 of the forward osmosis membrane, and the inner side of the water bag is the support layer 4, which is in contact with the drawing liquid. The specific method of the layer-by-layer self-assembly method of the forward osmosis membrane Proceed as follows:

[0027] (1) Preparation of layer-by-layer self-assembled forward osmosis membrane: configure cationic and anionic polyelectrolyte casting solutions, use ultrafiltration membranes as base membranes, cationic and anionic polyelectrolyte casting solutions as construction units, and adopt static alternating depositi...

Embodiment 1

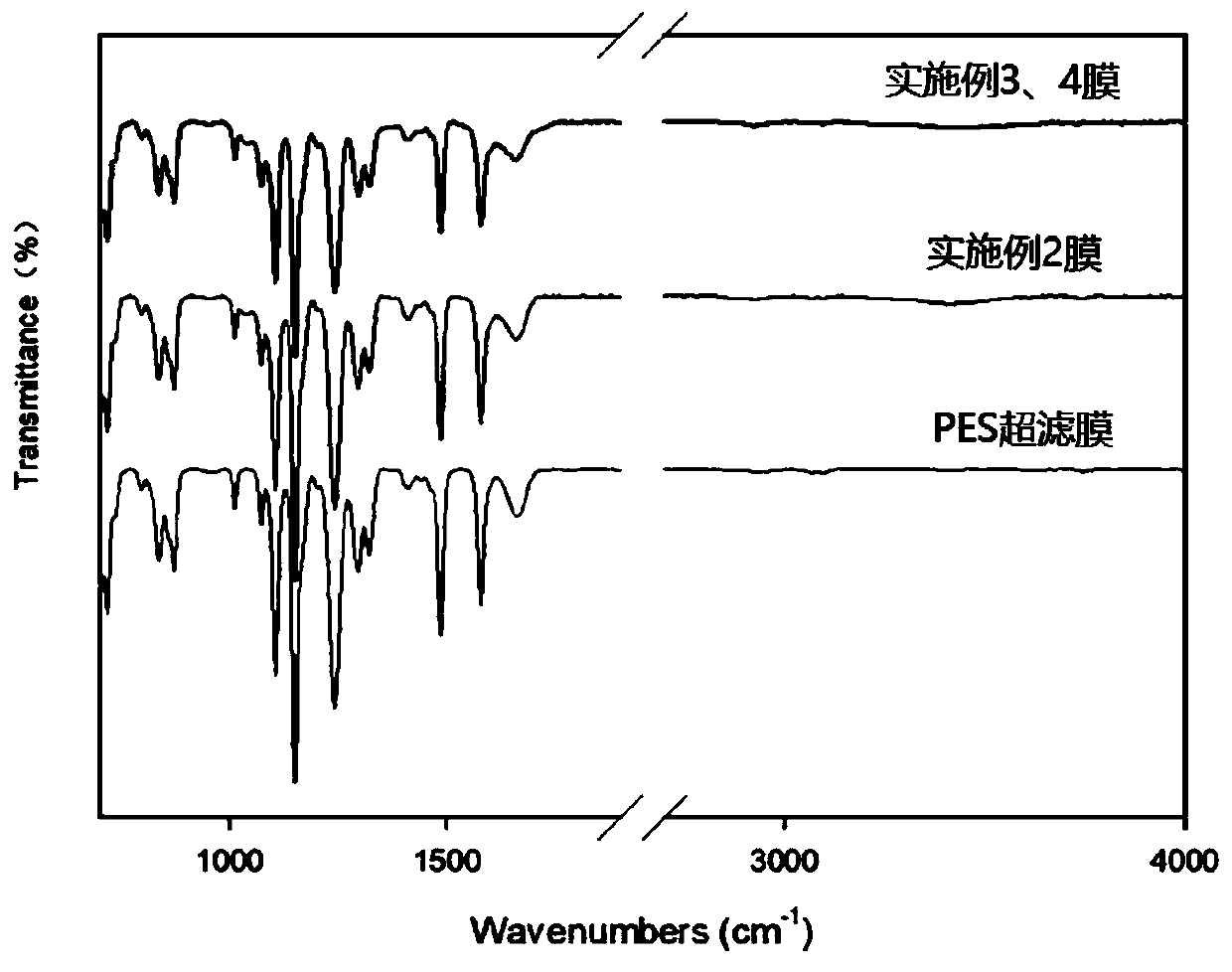

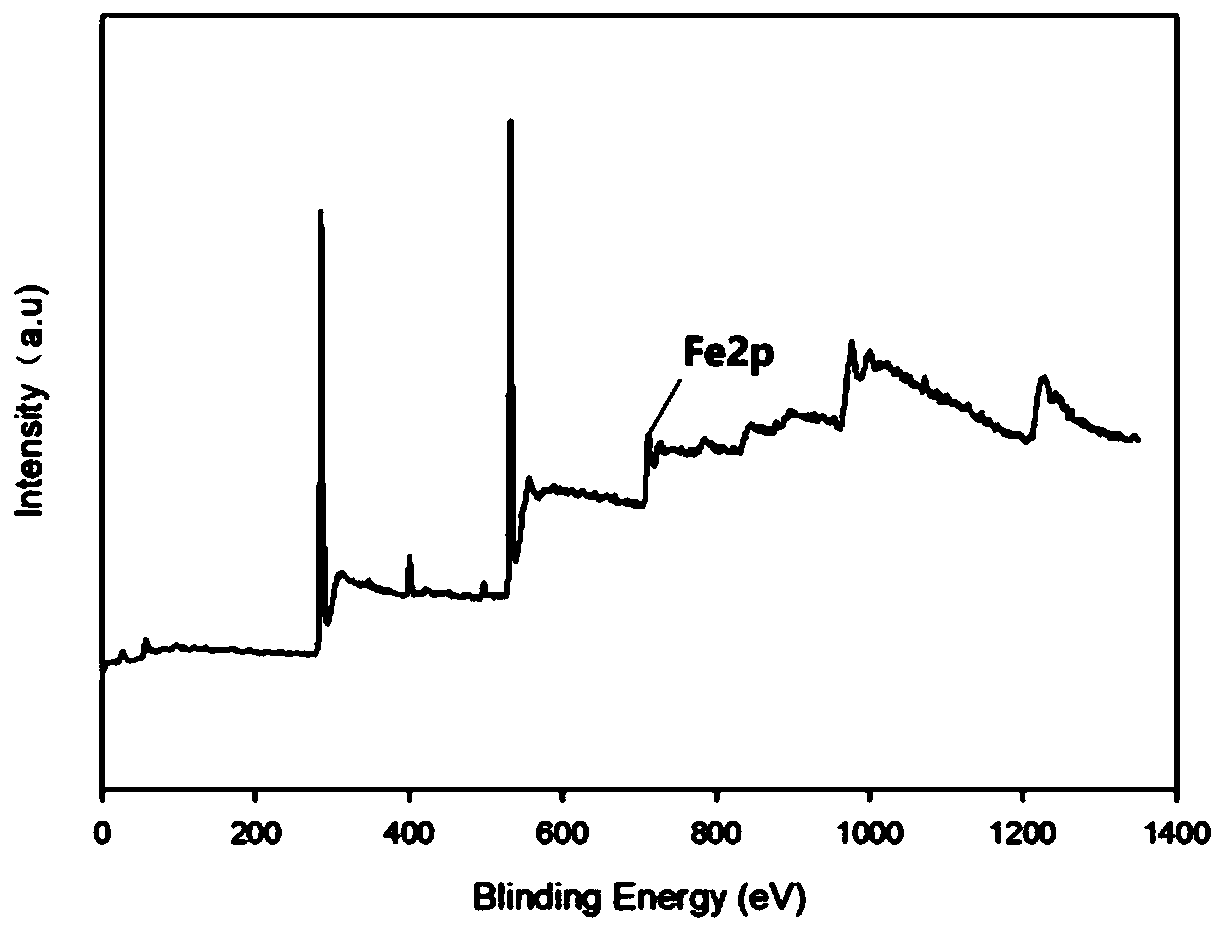

[0038] Preparation of forward osmosis membrane: prepare 1% acetic acid solution containing 2g / L chitosan as cationic polyelectrolyte casting solution, use NaCl to adjust the salt background concentration of casting solution to 0.1mol / L; prepare 1g / L sodium alginate The aqueous solution is an anionic polyelectrolyte casting solution, and NaCl is used to adjust the background salt concentration of the casting solution to 0.1mol / L. With the polyethersulfone (PES) ultrafiltration membrane with a molecular weight cut-off of 20000 Daltons as the base membrane, the cationic and anionic polyelectrolyte casting liquids are used as the construction unit, and the layer-by-layer self-assembly method of static alternate deposition (dipping coating layer self-assembly Method) Six layers of polyelectrolyte were deposited on the active layer of ultrafiltration membrane.

[0039] Specifically, rinse the active layer protective solution of the basement membrane of the ultrafiltration membrane w...

Embodiment 2

[0045] Preparation of forward osmosis membrane: prepare 1% acetic acid solution containing 2g / L chitosan as cationic polyelectrolyte casting solution, adjust the salt background concentration of casting solution to 0.1mol / L with NaCl; prepare 2g / L sodium alginate The aqueous solution is an anionic polyelectrolyte casting solution, and NaCl is used to adjust the background salt concentration of the casting solution to 0.1mol / L. With the polyethersulfone (PES) ultrafiltration membrane with a molecular weight cut-off of 20000 Daltons as the base membrane, the cationic and anionic polyelectrolyte casting liquids are used as the construction unit, and the layer-by-layer self-assembly method of static alternate deposition (dipping coating layer self-assembly Method) Six layers of polyelectrolyte were deposited on the active layer of ultrafiltration membrane.

[0046] Specifically, rinse the active layer protective solution of the basement membrane of the ultrafiltration membrane wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com