Technical method for recycling potassium, sodium and zinc from blast furnace bag ash

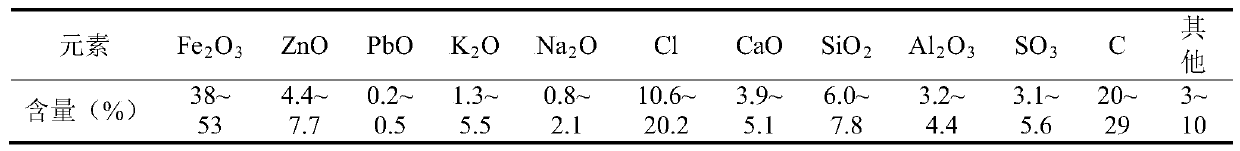

A process method, bag ash technology, applied in the field of waste resource utilization, can solve the problems of increased coke ratio, high-value utilization of blast furnace bag ash, and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

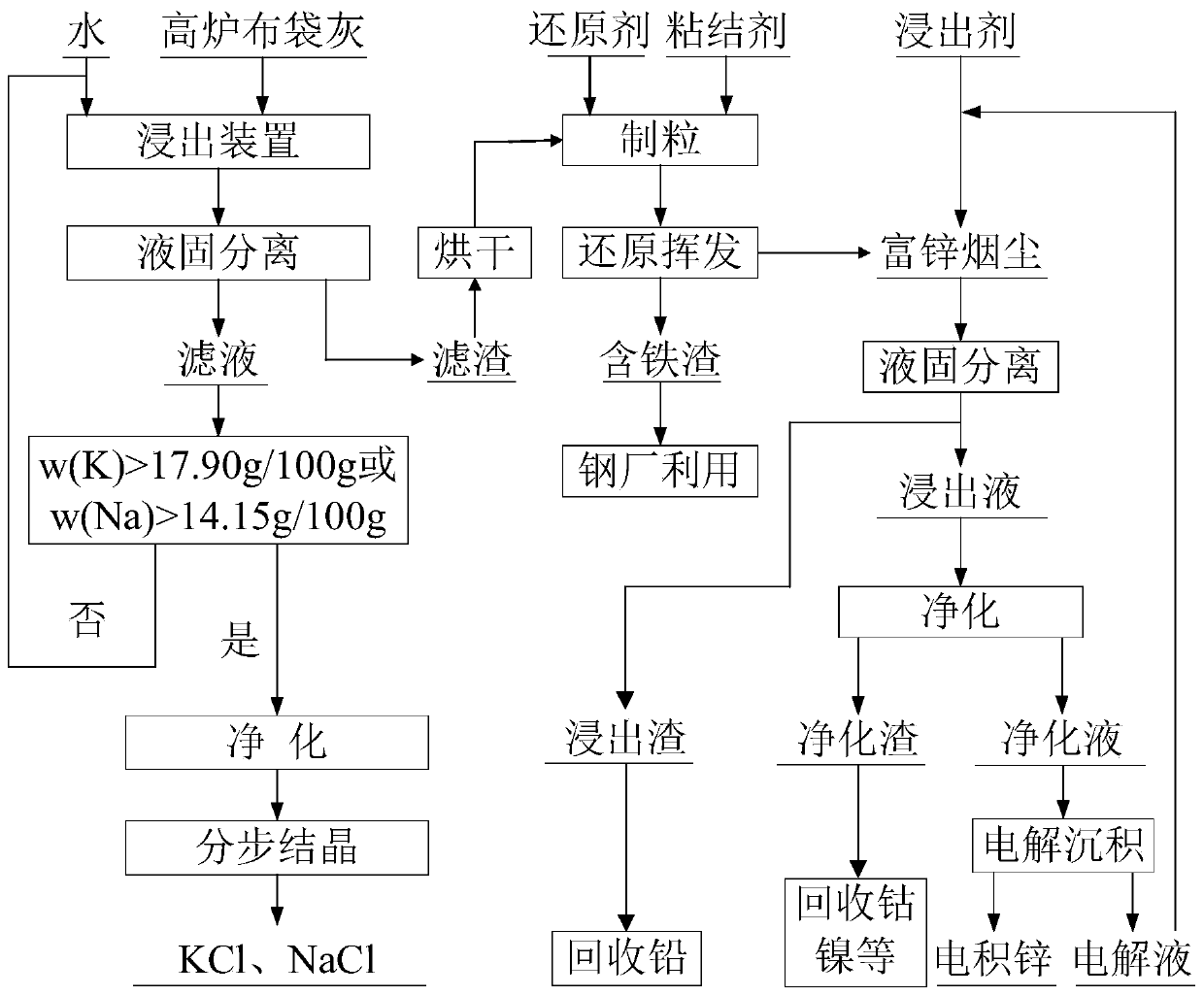

[0063] Such as figure 1 As shown, the process flow of the present invention includes the following processes: water washing recovery of potassium and sodium process, reduction of volatilized zinc process and wet recovery of zinc process.

[0064] (1) Potassium and sodium recovery process by water washing: After mixing water and blast furnace bag ash according to a certain liquid-solid ratio, wash with water at a certain stirring speed for a certain period of time, so that potassium and sodium can enter the washing liquid to the maximum extent, and then obtain the filtrate and The filter residue and the filtrate are purified and crystallized step by step to prepare KCl and NaCl products; the filter residue is used to recover zinc. As a preference, the liquid-solid ratio of water and blast furnace bag ash is controlled between 2:1-4:1L / Kg; the stirring speed is controlled between 50-100r / min; the washing time is 30-60min; liquid-solid separation is selected by pressure filtratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com