Arc pipeline corridor construction method

A pipeline construction and arc-shaped technology, which is applied in the direction of pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of unsatisfactory pipe gallery construction, complicated construction technology, waste of time, etc., and achieve good economic benefits and social benefits, avoiding air pollution, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the drawings and specific embodiments.

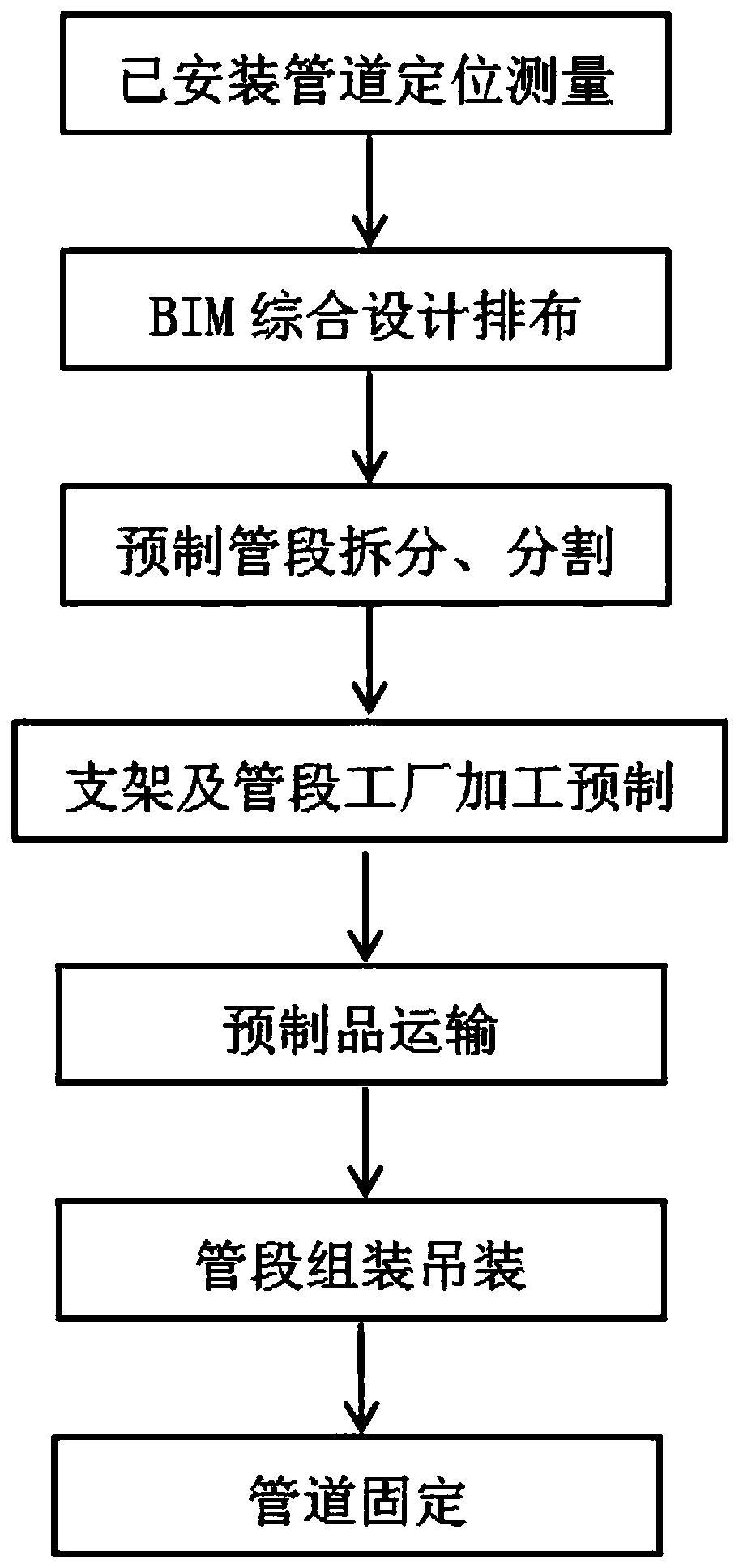

[0041] A method for constructing curved corridor pipelines:

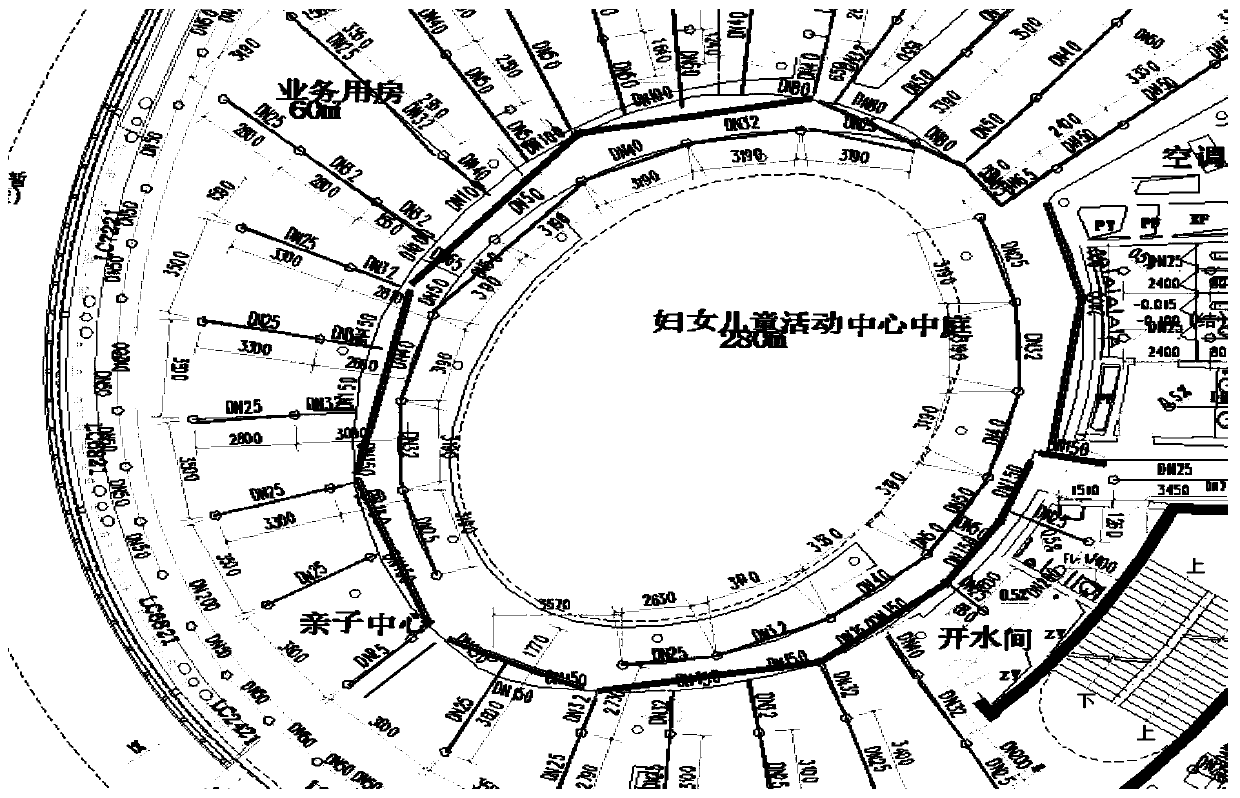

[0042] The process flow is pre-processed, and the pipe sections and accessories are processed and prefabricated in advance. When the arc-shaped pipe gallery has the installation conditions, the prefabricated pipe sections and accessories are transported to the pipe gallery for installation;

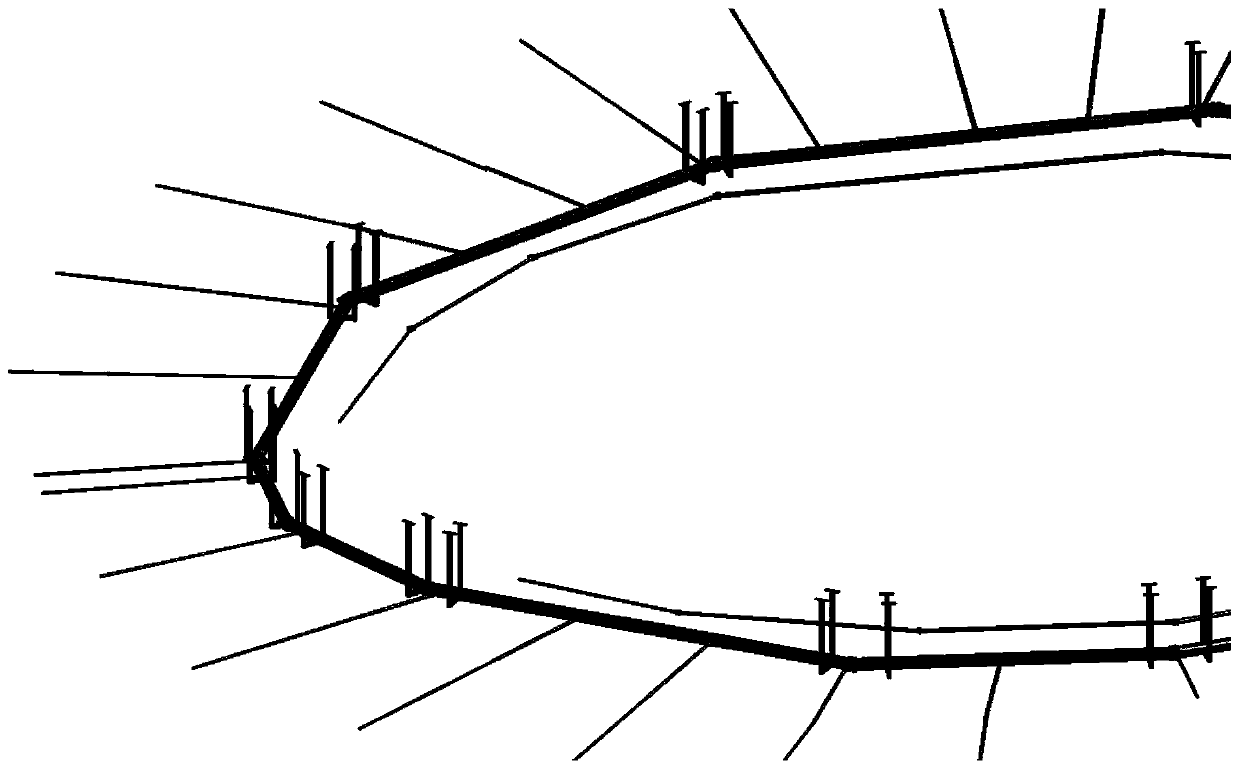

[0043] Factory processing and prefabrication of pipe sections and fittings, automatic processing according to the processing drawings designed by BIM accurate modeling, including automatic intersecting wire cutting machine cutting and automatic welding robot welding to improve processing quality and efficiency;

[0044] When installing the curved pipe gallery, modularly hoist the prefabricated pipe sections and accessories to speed up the hoisting speed;

[0045] When the pipeline is assembled, it uses full bolt conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com